ralph lauren polo ralph lauren case background

Even now, there are still many production manufacturing plants or factories that operate independently, without centralized monitoring mechanisms, intelligent controls and digital networks. Today, more and more newer factories are building digital factories from the ground up, with systems for process optimization, automated manufacturing, and predictive maintenance, but these transitions are more challenging for older, traditional factories.

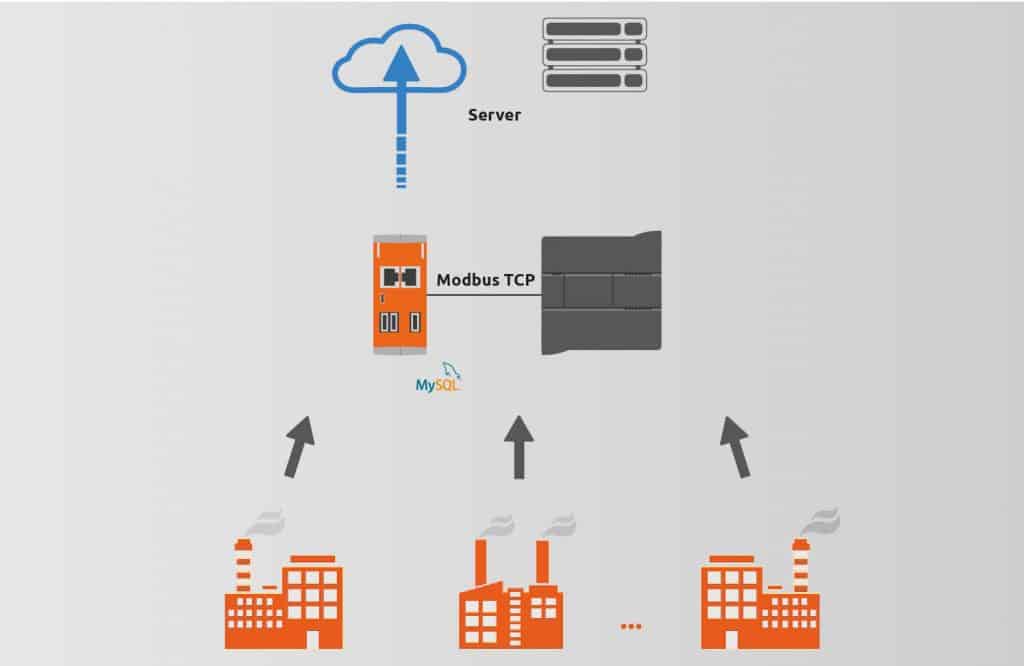

One of Thailand's leading palm oil producers found itself in just such a situation and was looking for a solution to help modernize its production facilities, which have a heterogeneous structure that has evolved over the years. Through TECHSQUARE, the local KUNBUS distributor, and its systems integration partner in southern Thailand, KPS Automation and Service, the first design with Revolution Pi Industrial Raspberry Pi was delivered to the Thai palm oil production industry. The plant took the first step in its transformation to Industry 4.0. A data center was implemented, designed to centralize all production data and thus ensure direct and effective monitoring of palm oil production.

ralph lauren polo ralph lauren solution- RevPi Connect+

In this case, the RevPi Connect+ module is used to communicate with Siemens S7 PLCs via Modbus TCP. For security reasons, the data on RevPi Connect+ is buffered locally before it is exchanged with the server. Engineers wrote a small application for data transfer in Python and used a special web service to centralize the processing and storage of production data on the server, as well as the computation within the control module. As a result, the server combines data from multiple palm oil production sites so that multiple RevPi Connect+ modules can be used at multiple production sites.

▍本文使用的模塊— RevPi Connect+

RevPi offers maximum freedom to the user due to its open platform concept (including full root access). RevPi has a 24-hour buffer of real-time time (RTC), ensuring that the device always has the correct time information, even in the event of a power failure. The operating system uses a customized version of Raspbian with real-time patching. Supports MQTT and OPC UA to transfer machine data directly to the cloud.

RevPi can be programmed via Node-RED, Python or directly in C. The modular design of RevPi allows the device to be fitted with the appropriate expansion modules, such as digital and analog IOs, and fieldbus gateways, as required. Expansion modules can be connected via connectors (plug and play) and easily configured using a graphical interface.RevPi already has master-slave functionality for both Modbus RTU/TCP network protocols, eliminating the need for additional expansion gateways.

Specification

| Specification | |

|---|---|

| processors | Broadcom BCM2837B0 with Quad-Core ARM Cortex-A53 (RevPi Connect+) Broadcom BCM2837B0 with Quad-Core ARM Cortex-A53 (RevPi Connect) Broadcom BCM2837 |

| Clock Frequency | 1.2GHz |

| Memory | 1 GB |

| Storage (eMMC) | 8 - 32 GB (RevPi Connect+) 4 GB (RevPi Connect) |

| Power supply | 12 - 24 volts |

| Dimensions (L x W x H) | 111 x 45 x 96 mm |

| Working Temperature | -25 °C...+55 °C |

| Storage Temperature | -40 °C...+85 °C |

| Humidity | 93 % (non-condensing) |

| Protection Level | IP20 |

| ESD Protection | 4 kV/8 kV |

| EMI Testing | Passed (according to EN 61131-2 and IEC 61000-6-2) |

| Surge/Surge Testing | Passed (according to EN 61131-2 and IEC 61000-6-2) |

| consistency | CE, RoHS |

| UL Recognition | Yes, UL File No. E494534 |

Interface Type

| connector |

|---|

| 2 RJ45 Ethernet sockets |

| 2 USB 2.0 sockets |

| 1 x mini HDMI socket |

| 1 x micro USB 2.0 socket |

| 1 x RS485 screw terminal (4 pole) |

| 1 x 24 V input for UPS shutdown signaling |

| 1 freely programmable relay switch contact |

| 1 x PiBridge (for RevPi expansion module) |

| 1 x ConBridge (for RevPi Con expansion module) |