Food Temperature and Humidity Monitoring Solutions

Temperature and humidity have a huge impact on the quality of food and beverages. Monitoring of the entire supply chain is essential for compliance and product quality.

Temperature and humidity have a huge impact on the quality of food and beverages. Monitoring of the entire supply chain is essential for compliance and product quality.

During the production, storage and transportation of food products, continuous temperature control is necessary to ensure food safety. This not only ensures the quality of the product, but also protects the health and safety of consumers. Cooked or frozen foods stored and transported outside the recommended temperature range can lead to the growth of bacteria and fungi. In order to comply with legal regulations and maintain products at the desired temperature, temperature deviations during production, storage and transportation must be alarmed and recorded as follows:

Temperature control of food is an important measure to prevent bacterial growth and food spoilage. If the temperature of food is not monitored and controlled during production, storage or transportation, bacteria may grow, leading to food deterioration, cross-contamination of pathogenic bacteria, etc. and increasing the risk of food poisoning.

Changes in temperature affect the taste, color, flavor and nutritional value of food. Failure to check the storage and transportation temperatures of food products may lead to a decline in food quality, even affecting the taste experience of consumers and reducing the competitiveness of the food products in the market.

In many countries and regions, the monitoring of temperature during food production, storage and transportation is a legal requirement. If a food business does not comply with these regulations, it may face fines, product recalls, reputational damage, and even warnings or closure by regulatory authorities.

Failure to check temperature may result in overheating or overfreezing of food during production and storage, causing damage or deterioration of some food products and increasing the risk of loss and food waste.

The perishable nature of foodstuffs depends to a large extent on the temperatures at which they are handled, stored and transported, and the DIN 10508 standard defines the ideal temperature range for the storage of various foodstuffs:

Fresh vegetables, whole fruits and cut fruits require different storage temperatures. Storing food correctly not only complies with all regulations, but also allows for optimal results during the shelf life of the food. Food temperature and humidity monitoring solutions.

Use professional temperature monitoring equipment, such as high quality temperature recorders, to regularly monitor and calibrate refrigeration equipment, heating equipment, ovens, etc. in food production.

Continuously monitor the temperature in the production environment, including production workshops, storage rooms, cold storages, etc., to ensure that the ambient temperature complies with food safety and quality standards. Establish a comprehensive monitoring system.

Monitor the temperature of ingredients during the food production process. Ensure that the temperature of raw materials and semi-finished products during the production process meets the requirements to avoid bacterial growth and food spoilage.

Strict temperature control in the cold chain during food storage and transportation. Temperature recorders are used to monitor the temperature of refrigerated vehicles, cold stores and freezing equipment to ensure that food products are kept at a suitable temperature throughout the supply chain.

Conduct regular temperature distribution verification of equipment, warehouses, storage rooms, etc. to ensure that they have good temperature control performance.

A temperature alarm system is installed to provide timely warning when the temperature exceeds the safe range. This allows for timely detection of problems and the adoption of measures to avoid food damage and safety issues.

The ELPRO Cloud Starter Kit includes everything you need to set up a GxP-compliant temperature monitoring solution, including a communication module and two wireless temperature data loggers.

Get started with our plug-and-play solutions in five minutes!

With ELPRO Cloud, you get an intuitive and efficient reporting tool that visualizes sensor activity and generates reports when you need them.

Your starter kit includes a coupon for a free software license for the first year of our ELPRO Cloud surveillance system!

WiFi Temperature and Humidity Sensor - Built-in Temperature and Humidity Probe

Built-in Sensor Temperature and Humidity Recorder

Internet of Things Wireless Temperature and Relative Humidity Data Logger

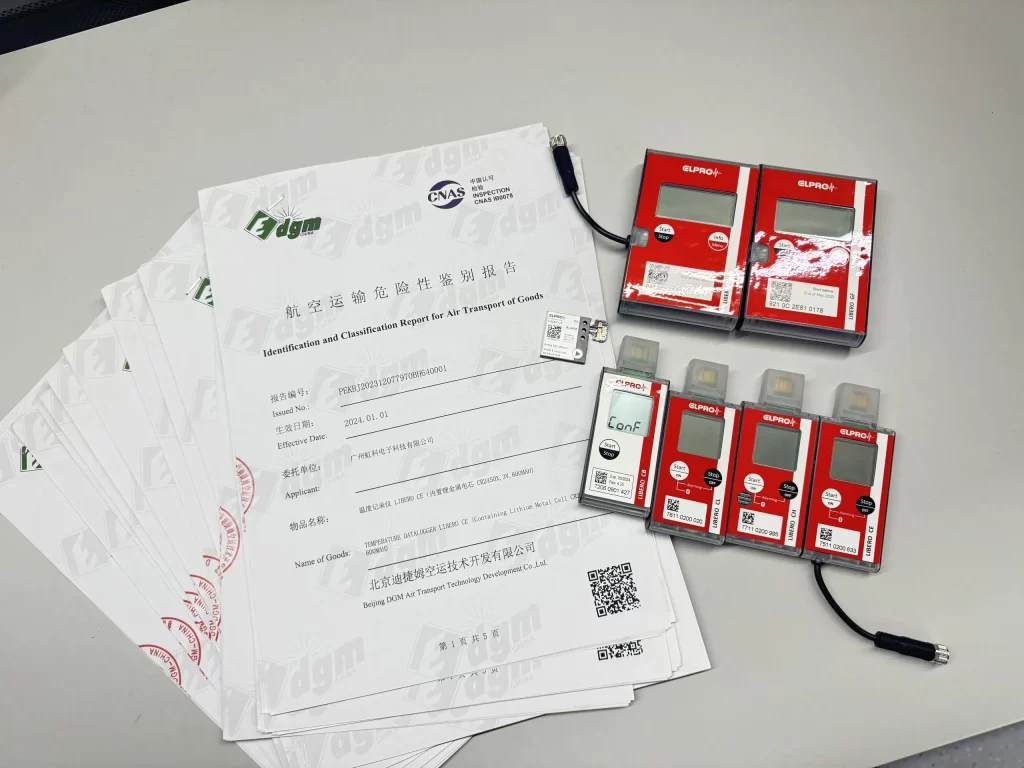

All of the liquid nitrogen tank transportation and storage temperature monitoring products provided by Honghong have obtained the aviation safety appraisal report (Cargo Transportation Condition Appraisal Certificate) from Beijing DGM and Shanghai Institute of Chemical Technology, and can be safely transported by air.

Our professional Honghong team will be the first to respond and provide you with the best service to solve all your problems.

Address: 3F, No. 99, Jingye 1st Road, Zhongshan District, Taipei City, Taiwan (Da Wan Technology Center Building)

3rd Floor., Dawan Technology Center Building, No. 99 Jingye 1st Road, Zhongshan District, Taipei City, Taiwan

©2025.hongtronics. All Rights Reserved.