故Obstacle phenomenon

一Vehicle 2013 Land Rover Freelander 2 with 2.0L Si4 Petrol engine, totaling about 45,000 miles.

Owners have reported that their vehicles occasionally fail to start. When the malfunction occurs, after trying to start the engine, the instrument panel will display "gear not in P" and "charging system malfunction", etc., when the center display does not light up. After a period of time, the instrument panel will turn off automatically. If you press the ignition switch again, the instrument panel will display "Key not found". After waiting for a while, the malfunction phenomenon will disappear.In the past year, this kind of failure has occurred seven or eight times, especially in the case of theDuring the winter months, the frequency of malfunctions is higher, but theThere's no obvious rule.。

故Barrier Diagnosis

First, we conducted a test drive. As it was an occasional fault, the fault was not reproduced at that time. Using a fault detector, we found that the vehicle had several fault codes starting with "U", pointing to the medium-speed CAN bus. A network integrity test was carried out using the fault detector and all control units were able to communicate normally. In order to further confirm whether the fault is caused by the medium-speed CAN bus, fault simulation is carried out: press the ignition switch to start the engine, and artificially short-circuit the CAN H and CAN L of the medium-speed CAN bus, the fault phenomenon is consistent with the owner's description.

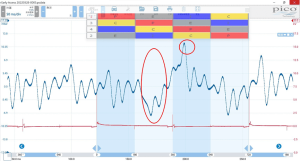

Figure 1: Fault Codes Stored in the Vehicle

First, we conducted a test drive. As it was an occasional fault, the problem was not reproduced at that time. Using a Pico oscilloscope for fault detection, the vehicle was found to have a number of fault codes starting with "U", pointing to the medium-speed CAN bus. A network integrity test using a Pico oscilloscope showed that all control units were communicating normally. Therefore, in order to further confirm whether the fault is caused by the medium-speed CAN bus, a fault simulation was carried out: by pressing the ignition switch to start the engine, the CAN H and CAN L of the medium-speed CAN bus were artificially shorted out, and the fault phenomenon was consistent with the owner's description.

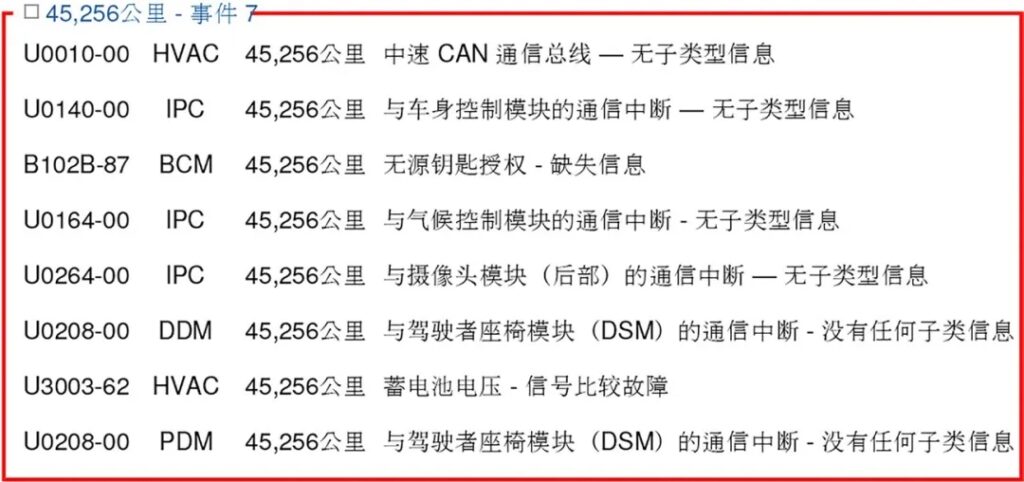

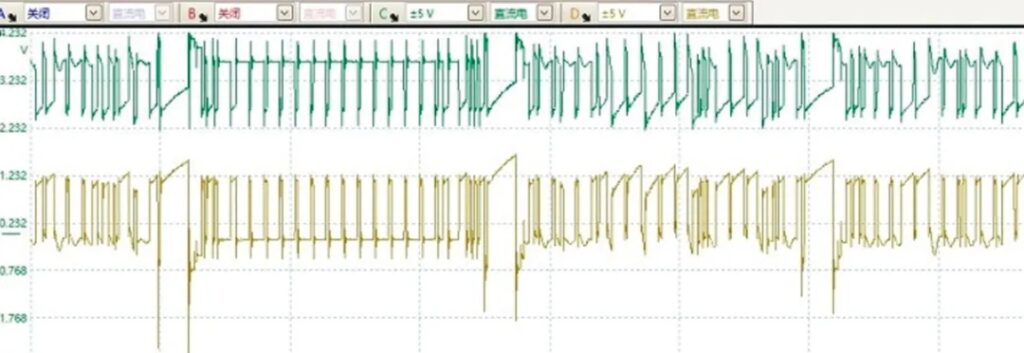

Install the medium-speed CAN bus, test drive repeatedly, and measure the medium-speed CAN bus signal waveforms with a Hongke Pico oscilloscope, and the waveforms are normal (Figure 2). By simulating the vibration and knocking the control units on the medium-speed CAN bus one by one to test, the fault phenomenon can not be reproduced. Check that the wire connectors of each control unit are connected normally, and the relevant wires are not damaged. On the advice of the manufacturer, it was decided to replace the body control module and hand over the vehicle to the owner. Seven months later, the owner reported that the malfunction had reappeared, and twice in the last half month, so the malfunction was obviously more frequent.

Fig. 2: Medium-speed CAN bus signal waveform is normal.

The Pico oscilloscope was used again and the fault codes were still present. Since all the faults occurred when the vehicle was started, an attempt was made to simulate an owner's use of the vehicle. During the test, it was found that when the vehicle was unlocked for the first time after a long period of locking (vehicle hibernation) and the left front seat switch was operated immediately, the left front seat would not be adjusted. After turning on the ignition or starting the vehicle, and then operating the left front seat switch, the left front seat still could not be adjusted. After unlocking for about 40 seconds, the adjustment of the left front seat switch returns to normal, but the malfunction does not reappear at this time. Compared with a normal vehicle, after locking the vehicle for the same length of time and then unlocking it, the left front seat switch adjustment function can be operated normally immediately, thus indicating that the faulty vehicle left front seat switch adjustment function is abnormal.

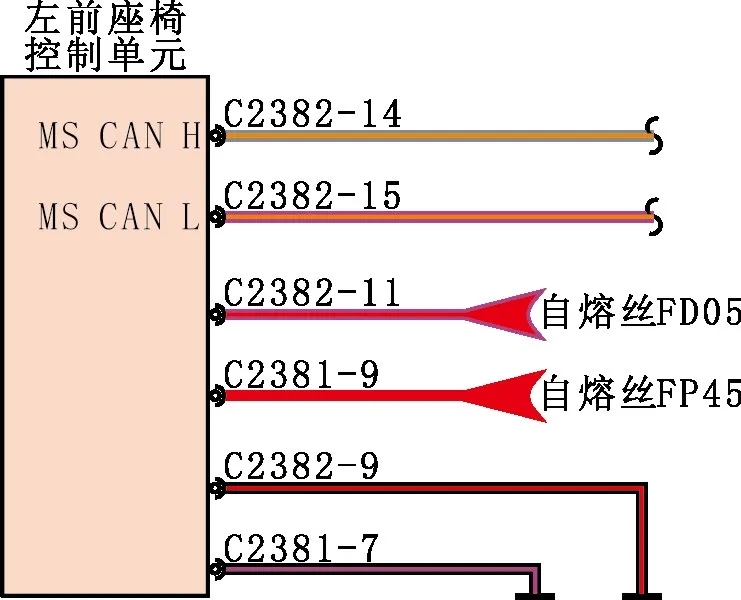

According to the left front seat control unit control circuit (Figure 3), using a multimeter to measure the left front seat control unit power supply, iron are normal.

Figure 3: Left Front Seat Control Unit Control Circuit

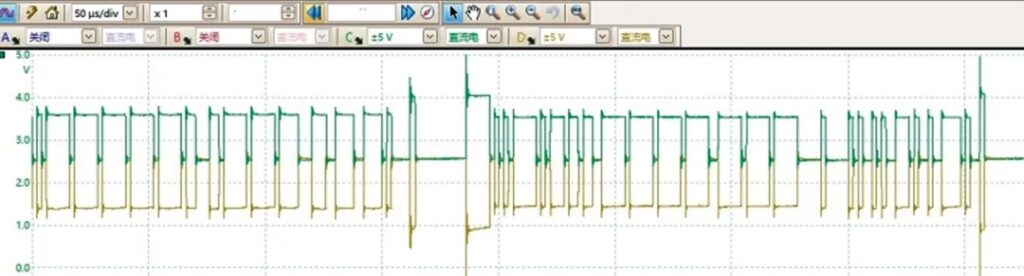

When the left front seat switch adjustment function is abnormal, the waveform of the medium-speed CAN bus signal is obviously abnormal (Fig. 4), and the waveform returns to normal after about 40 seconds, and the left front seat switch adjustment function also returns to normal at this time.

Figure 4: Medium-speed CAN bus signal waveform abnormality

After disconnecting the left front seat control unit wire connectors C2381 and C2382, lock the vehicle for a long time, and then measure the medium-speed CAN bus signal waveform when the vehicle is unlocked and activated, and the result is normal, which confirms that the left front seat control unit is faulty, resulting in the malfunction phenomenon.

Fault Replacement

Replace the left front seat control unit, use Pico oscilloscope to perform the left front seat control unit replacement program, lock the vehicle for 20 minutes, immediately after unlocking, operate the left front seat switch, the left front seat can be adjusted. The left front seat could be adjusted. All the test drives were normal, so the vehicle was handed over to the owner. A month later, the owner reported that the problem did not recur, so the problem was solved.

Fault Summary

When dealing with such low-frequency, long-interval episodic failures, it is very difficult to capture the communication state at the time of the failure. For this reason, we propose the following steps:

- Understanding the Scene of Use:Detailed understanding of the owner's usage scenarios and simulations are performed to better reproduce failures.

- Test related control units:Test the functional status of all relevant control units to detect other phenomena that may have been overlooked by the customer.

- Troubleshooting easily reproducible faults:Prioritize those faults that are easy to reproduce and easy to troubleshoot, which may also address related complex and difficult to reproduce faults.

In addition, Acer's Pico oscilloscopes are equipped with real-time display and recording functions, which are very effective in helping to capture occasional fault signals without missing any instantaneous signal changes.

-e1718934454624.jpg)

Acer Pico Automotive Oscilloscope Kit

Acer Pico Automotive Oscilloscope KitDiagnose faults in any vehicle with engine or motor, widely used in automobiles, ships, aircraft, construction machinery and stationary equipment.Such as large generators. A wide range of routine tests can be performed, including: sensors, actuators, relative compression testing, etc. To learn more, please refer to ourProduct Introduction Page。

Find the test equipment you need today and contact us to talk about it. We'll show you what Pico oscilloscopes can do for you. For more information about CAN bus systems, please refer toWikipedia entry on CAN buses。