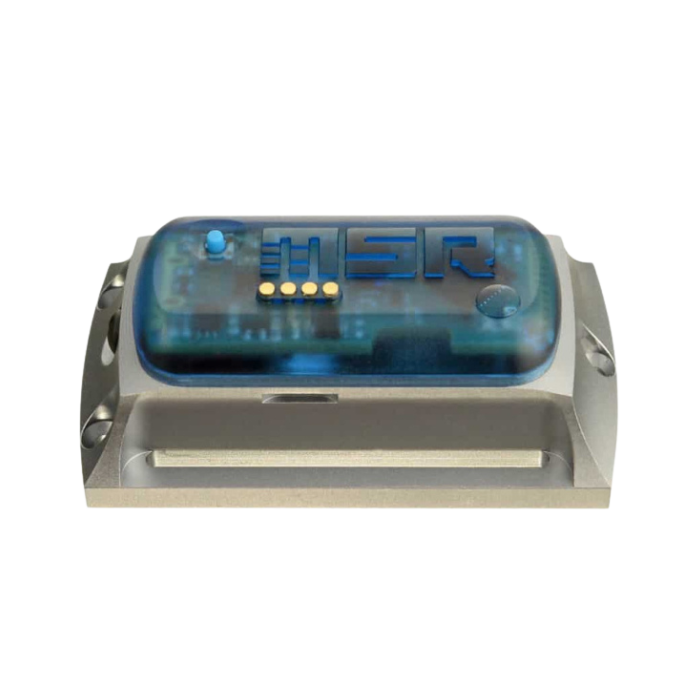

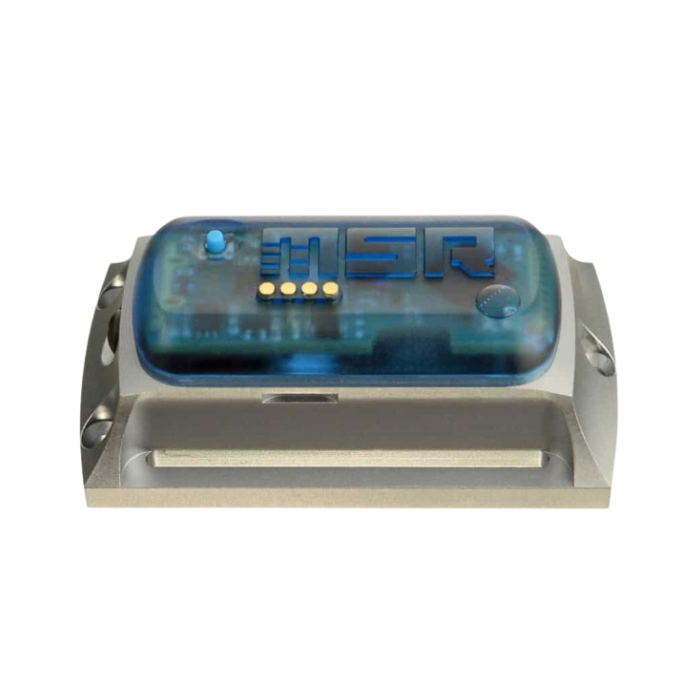

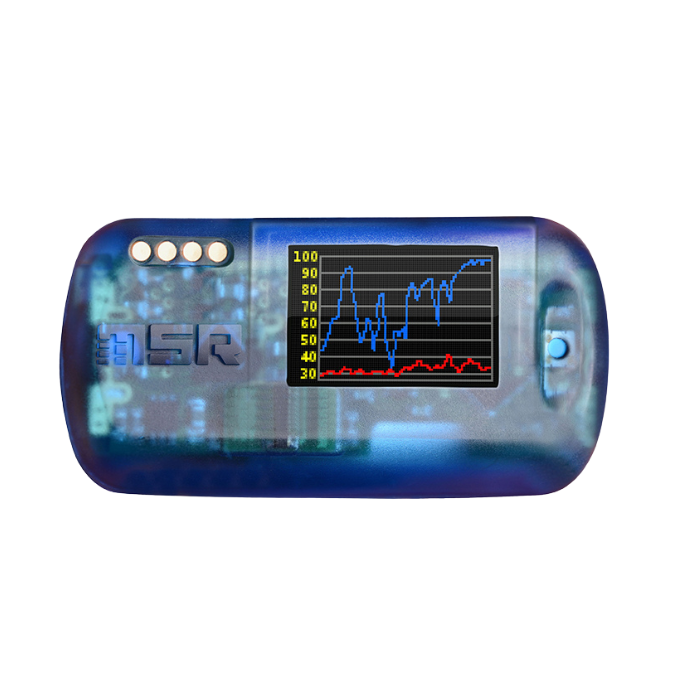

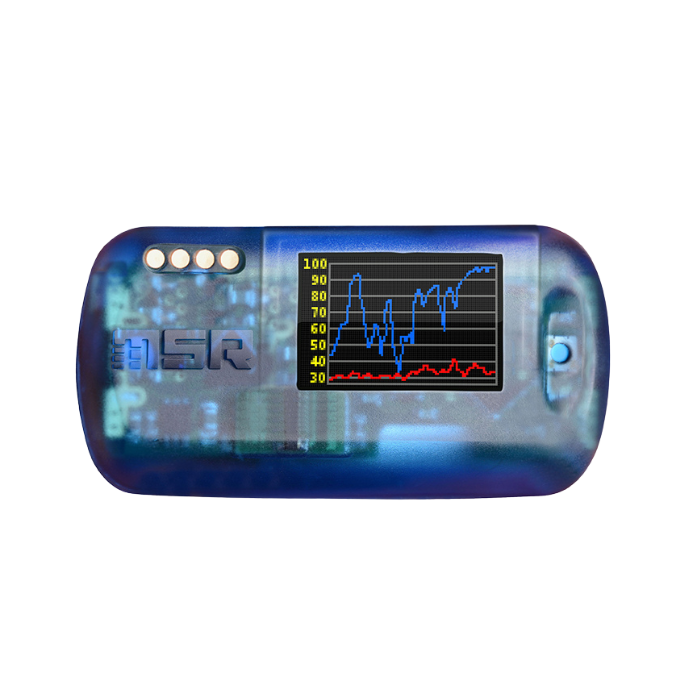

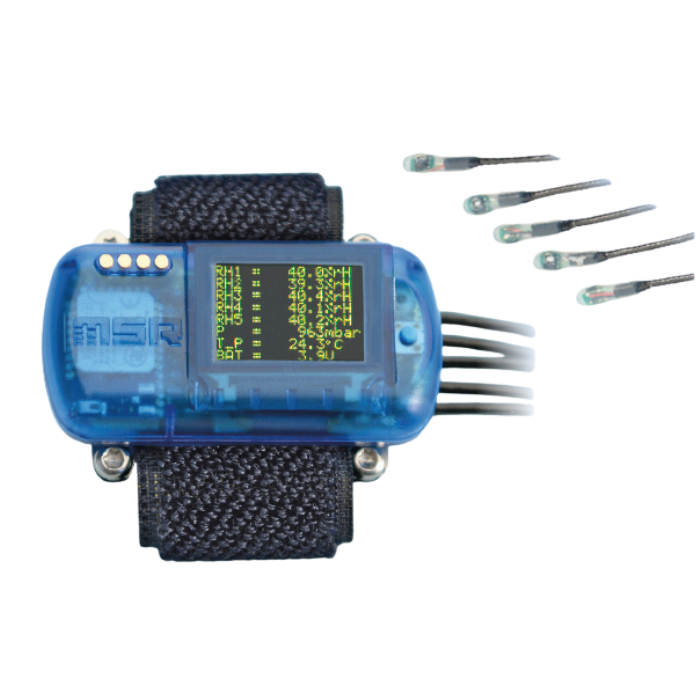

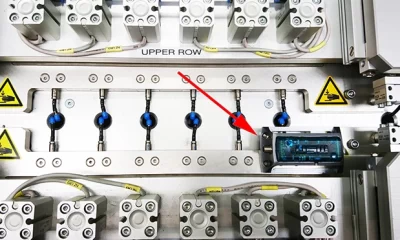

Sensitive goods such as precision machinery, chemicals or electronic equipment are exposed to a variety of risks during transportation. Whether transported by road, rail, water or air, the threat of collisions and tipping events exists both during loading and in transit. Similarly, changing environmental conditions can cause damage to the goods being transported.Data loggers use sensors to monitor various environmental parameters such as temperature, air pressure, humidity, lighting conditions and/or mechanical dynamic loads such as shocks and impacts.

Acceleration (shock, collision) is recognized as the main cause of transportation damage.

Impact events during transportation can have a very negative effect on the mechanical structure of any industrial or consumer product. Damage is not always visible externally, which makes the data recorded by acceleration sensors all the more important as they can be used to clarify liability and quality assurance issues. In addition, even if the goods being shipped are insured, the insured loss is often only a small part of a potentially much larger overall loss. Consideration must also be given to consequential losses due to incorrect transportation, such as losses due to missing goods, unplanned follow-on production, delays or business interruptions. Choosing the right impact data logger depends on the goods being transported and the purpose of the logging. Are you looking to optimize your packaging by measuring the loads on your shipment through a drop test or test shipment? Are you recording shipments as a precautionary measure so that any damage to the goods can be detected early? Is it to record shipments that last several weeks in order to comply with standards and regulations?

Temperature and humidity are important parameters in cold chain monitoring.

If the goods are perishable goods or highly regulated goods such as frozen products, pharmaceuticals, organs or even plastic components.Temperature and humidity limits and standards must be adhered to and fully documented during transportation and storage.。

Relative HumidityIt is closely related to temperature through the dew point parameter. Humidity must also be recorded, e.g. in order to be able to quickly determine the cause of corrosion on metal parts or the cause of moisture and mold damage on organic materials.

Light intensity(lux)It is also an important factor for physical influences such as foodstuffs and chemicals, as solar radiation often has a damaging effect on sensitive goods. However, the "light" parameter is particularly important for detecting unauthorized operations in normally sealed containers: the incidence of light indicates that the container has been opened, which may lead to conclusions about planned or executed thefts.

Air PressureIt is also an important value which can, for example, influence the properties of deformable goods. In this context, reference should be made to hollow objects made of plastic and to deformables filled with gases or liquids. This parameter is particularly important for the transportation of air cargo, since the air pressure inside the aircraft needs to be closely monitored.