Honghong Diagnostics | 2008 BMW X5 3.0Si K-CAN Bus Troubleshooting and Repair

Failure phenomenon

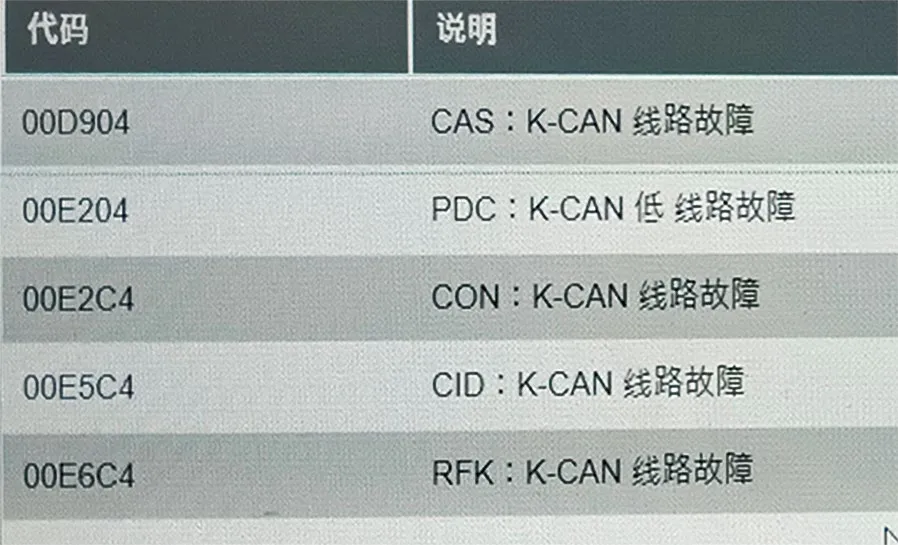

A 2008 BMW X5 3.0Si with N52B30BF engine has accumulated mileage of approximately 190,000 kilometers. When the vehicle was inspected by Diagnostic Troubleshooter during factory maintenance, it was found that several control units, including the Suspension Height Control (EHC), Keyless Start Control (CAS), Park Distance Control (PDC), Center Touch Display (CID), and Reversing Camera Module (RFK), had stored the fault code of "K-CAN Bus Fault" as shown in Fig. 1 below, and could not be cleared. cannot be cleared.Initially, the K-CAN bus of this vehicle may have an abnormality.

Fig. 1|K-CAN Error Codes Stored in the Control Unit

Fault Diagnostics

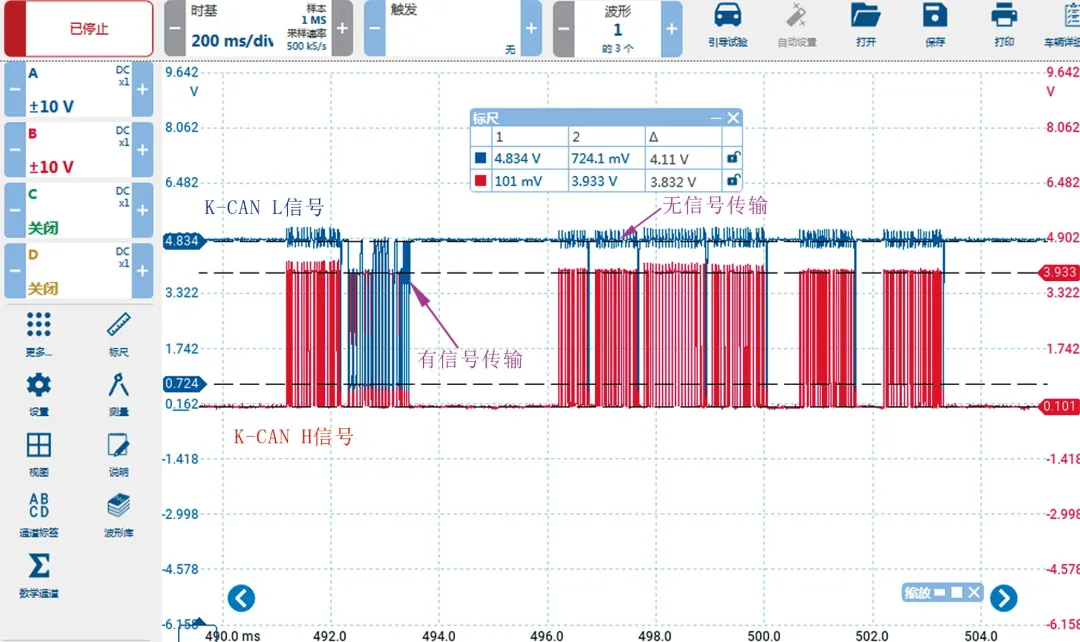

The K-CAN bus signal waveform is measured from the EHC module side using an Acer Pico automotive oscilloscope (see Figure 2):

K-CAN H line The signal is transmitted normally when the low level is about 0.1 V and the high level is about 3.9 V.

K-CAN L lineThe signal amplitude is normal, but the signal is lost frequently.

Note: The vehicle's K-CAN bus has a communication rate of 100 kbit/s, which is a low-speed CAN system that can maintain communication in a single-wire situation.

Based on the results of waveform analysis, it can be determined that the waveform characteristics are consistent withK-CAN L line openThis means that even if one line is down, the other line can still maintain communication. That is, even if one line is interrupted, the other line can still maintain communication, so it can be initially recognized as aK-CAN L line break fault。

Fig. 2|Waveform of K-CAN bus signal during failure

Further inspection of the K-CAN bus circuit reveals that there is a total ofFour Docking Points:

1. X15001 and X15002

2. X15003 and X15004

3. X15005 and X15006

4. X15011 and X15012.

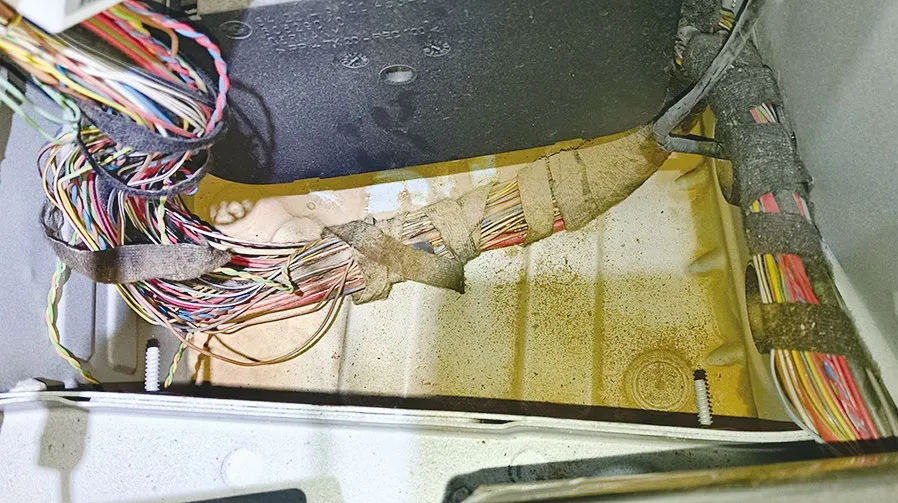

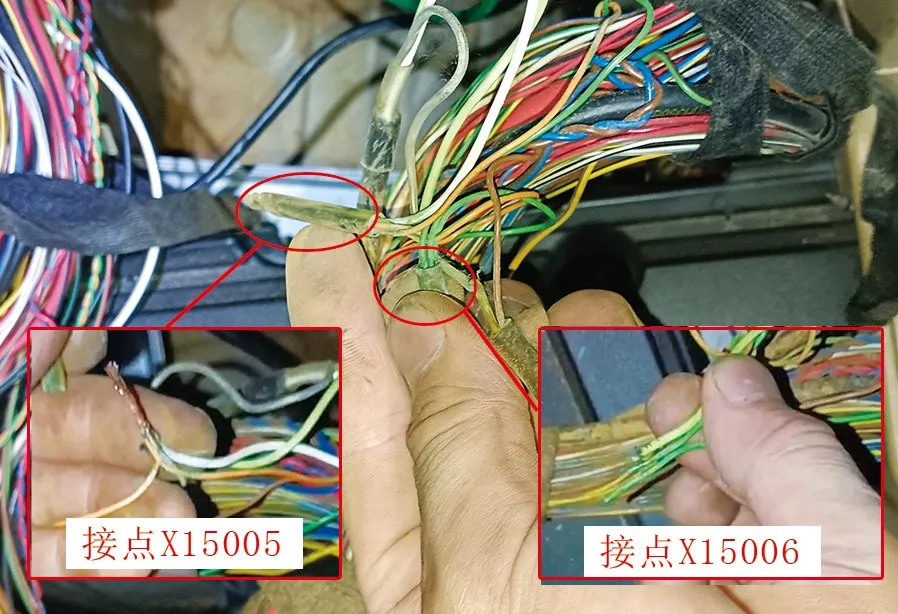

Since oxidized or loosened contacts are a common problem, the technician prioritized checking the contacts X15005 and X15006 on the right side of the rear row, and found that there was a problem inside the wiring harness. Water seepage marks(See Figure 3).

Fig. 3|Water seepage marks inside wiring harnesses

After stripping the wiring harness, a contact was found. X15006 Obvious oxidized corrosion(See Figure 4). The K-CAN L wire breaks when gently pulled and tested; it is assumed that the fault is caused by this contact. And the contact X15005 also slightly oxidizedThe K-CAN H line can communicate normally because it is not in contact with the K-CAN H line, but still maintains contact.

Fig. 4|Contact X15006 oxidized heavily

fault resolution

The technician repaired and soldered the wires at X15005 and X15006, completed the waterproofing and insulating treatment, and then tested the car again. The fault code "K-CAN bus fault" has been successfully cleared and the system resumes normal communication, which means the troubleshooting is complete.

Fault Summary

The K-CAN bus of this vehicle has a communication rate of 100 kbit/s and belongs to theLow-speed CAN systemTherefore, even if a single line is disconnected, some communication functions can still be maintained.

However, when the amount of transmitted data on the bus increases, signal loss becomes more pronounced, resulting in some functional limitations. This fault case sharing shows that using theHigh Resolution Pico Automotive OscilloscopesThe CAN bus can be used to determine the type of CAN bus abnormality, and can still communicate even if the bus is disconnected on a single line, but the CAN bus can be used to communicate even if the bus is disconnected on a single line.Be aware of potential delays and data loss.Water seepage in wiring harnesses and oxidized connectors are common causes of vehicle communication system failures and need to be addressed.Special inspection of environmental sealing。