What is IO-Link?

IO-Link is a fieldbus-independent, open point-to-point communication that is an industrial communication interface for devices at the lowest level of industrial control (e.g., simple sensors/actuators), enabling the integration of devices into virtually any fieldbus or automation system.

Unlike traditional field buses, the IO-Link protocol enables the connection of the device layer (sensors, actuators) to the controller with standardized IO, so that the controller can directly access the device layer and not just stay at the remote IO module or extended IO module. This fully digital transmission helps to solve the data isolation problems of traditional signaling modes and enables the integration of both traditional and intelligent sensors/actuators in automation systems.

IO-Link technology has the advantages of strong anti-interference ability, no signal loss, simplified wiring network, disconnection monitoring, etc., and has a very broad application prospect.In line with the trend of Industry 4.0, we have launched an embedded module, HK-IOLD-OEM, which is transplanted with IO-Link device protocol stack.

HK-IOLD-OEM

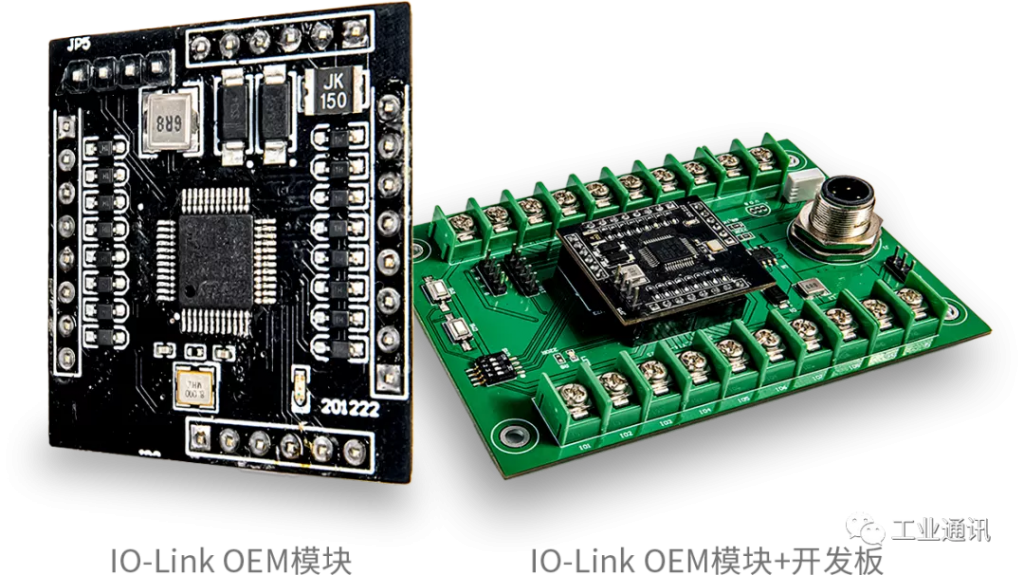

IO-Link OEM Modules

Rapid introduction of IO-Link technology

The IO-Link OEM module released by HONGKEI has transplanted the IO-Link device protocol stack and opened up the USART interface for user MCU to communicate. Simply by exchanging the real-time process data through the USART serial port, you can expand the IO-Link interface on non-IO-Link devices (sensors, actuators or hubs) to meet the development needs of various sensors, actuators or analog hubs, allowing you to easily and quickly develop IO-Link functionality on your devices. It meets the development needs of various types of sensors, actuators, or analog hubs, and allows you to easily and quickly develop IO-Link functionality on your devices.

Key features -IO-Link OEM Module

HK-IOLD-OEM

- Plug and play, no need to transplant the protocol stack, shorten the time to market.

- Flexible expansion for rapid development of IO-Link sensors, actuators, IOs and other IO-Link slave devices.

- The main MCU of the device interacts with the module through the USART interface.

- With 16 IO signal pins, it can meet the design of 16-point digital IO, and can be configured as 16DI, 16DO or 8DI8DO.

- Small module size meets most IO-Link slave design requirements

- Customized development services are available

For the convenience of users, HONGKOT has launched an evaluation kit for this IO-Link OEM module, which can assist the evaluation test and configuration of the IO-Link OEM module, greatly reducing the user's development workload.

Hi-Tech Electronics IO-Link Evaluation Kit

Key Features-HongKe IO-Link Evaluation Board

- The evaluation board supports USART serial interfaces, one for USART communication with OEM modules and one for printing messages.

- Evaluation board with 16 IO signal terminals, through the hardware lead OEM module IO signals

- Evaluation board with humidity sensor, infrared distance sensor development routines.

- The main chip of the evaluation board is STM32F103C8T6, and the development routines are written based on this model chip.

Contact Honghong Electronics