preamble

Wet heat sterilization method mainly refers to the use of saturated water vapor, boiling water or circulating steam sterilization method, high temperature and high pressure water vapor as a medium, due to the high latent heat of the steam, strong penetration, easy to make the protein denaturation or coagulation, resulting in the death of microorganisms, is the most commonly used in the production process of pharmaceutical sterilization methods.

(i) D-value

Tolerance parameter of microorganisms refers to the time required to reduce the number of microorganisms by one logarithmic unit or to kill 90% at a specific temperature. the larger the D value, the greater the heat tolerance of the microorganisms. the D value needs to be specified with reference to the temperature, i.e. it is expressed in DT, e.g. D121℃=1.5 minutes, which means that it will take 1.5 minutes to kill microorganisms of 90% under the 121℃ condition.

1,Examples of Microorganism D-values

(1)Thermophilic fat bacilli:The most thermally resistant microorganisms are known to have D121°C values between 1.5 minutes and 3 minutes.

(2)Staphylococcus:Often the “culprit” of cleanroom contamination, D121°C value is about 0.25 minutes.

(3)Clostridium spp:Typically highly resistant to “normal flora, D121°C value is about 0.8 min.

(4)Pseudomonas aeruginosa:Normally present in water, D121°C value is about 0.17 min.

2. D values in different media

D values of thermophilic Bacillus subtilis at different temperatures and in different media:

(1) The same microorganism in the same solution has different D values at different temperatures;

(2) The same microorganism has different D values in different solutions at the same temperature.

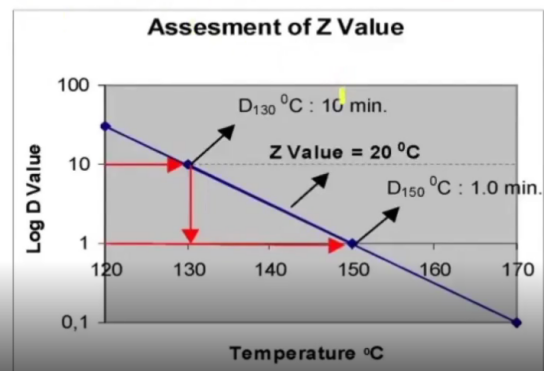

(ii) Z-value

The temperature at which the D-value of a microorganism is raised or lowered by one logarithmic unit. Often used to accumulate the killing time of a sterilization procedure as a function of temperature during the heating and cooling phases.

(iii) Sterilization rate Lethal Rate , L

1,Sterilization rate:This is the standard sterilization time for 1 minute of sterilization at a given temperature T(°C), expressed as L. L(Tref, z) = 10(T-Tref)/z

Tref Index Sterilization Temperature

2F0:means the equivalent sterilization time for a wet heat sterilization procedure to sterilize the sterilized product at 121°C when Z is taken at 10°C.

(iv)Sterility Assurance Level, SAL

Probability of microorganisms remaining in the product/item after sterilization. Describes the probability of a non-sterile unit after sterilization. Sterility assurance level ≤ 10-6, i.e., the probability of microbial survival after sterilization is less than 1 in a million.

(v)Balance Time

The time interval between the sterilization chamber (the chamber reference temperature is usually the drain probe temperature) reaching the minimum set sterilization temperature and the load reaching the minimum set sterilization temperature as measured by the slowest heating heat penetration probe. It demonstrates the ability of the sterilizer to remove air from the load and heat the load.

(vi)Biological Indication (Bl)

1,Bioindicator:Sterile carriers with established resistance to specific sterilization treatments that are packaged in an inner packaging and are ready for use.

2. Steam sterilization of commonly used BI strains - thermophilic fat spores, two important quality parameters: spore content and D-value.

(vii)Antibacterial(Sterilization)

A process used to achieve a specified probability of microbial survival for a product.

(viii)Sterilization Procedures(Sterilization Cycle)

A program consisting of a series of operating parameters (e.g., time, temperature, pressure) and conditions that render an object sterile.

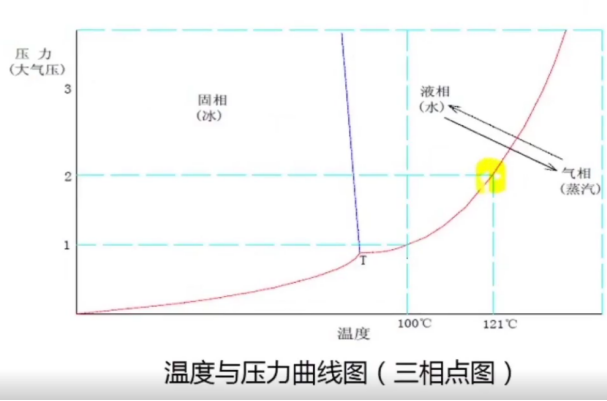

(ix) Principles of sterilization

At 121℃, water undergoes a phase change and generates a large amount of heat. When the saturated steam comes into contact with the sterilized material, a phase change occurs and the saturated steam turns into water, generating a large amount of heat, which kills the microorganisms.

1, water at different temperatures saturated vapor pressure: 121 ℃ corresponds to two atmospheric pressure, 134/135 ℃ corresponds to three atmospheric pressure

The relevant regulations for moist heat sterilization: EN285 UK, GB8599 China, HTM USA - Requirements for Steam Sterilization Cabinets

(x) Basic requirements for sterilization

1. Sterile drugs should be ultimately sterilized by heating as far as possible.

2. The SAL sterility guarantee value shall not be higher than 10-6.

3、Load mode confirmed by verification

4、Re-validation cycle of sterilization process: up to one year.

(xi)Sterilization Standards

1. Physical indicators:Temperature time curve; F0 value

2. Bioindicator (bio-indicator):Reduced by 6 log values, positive control experiment

The most commonly used sterilization criterion is the F0 value.

Since 1949, Avision Ellab has been your validation partner, providing the pharmaceutical and biotechnology industries with leading accuracy and quality thermal validation solutions, including the wired temperature system E-Val Pro and the wireless temperature verification system TrackSense Pro, with hardware and software designed and manufactured at our headquarters in Denmark. Ellab provides verification equipment and IQ/OQ services, as well as rental and calibration services, and has earned the trust of our customers with our professional customer support program, including technical support, on-site and factory calibration, and service capabilities. ellab serves large, medium, and small companies in the pharmaceutical, medical, and food industries, and covers virtually all in-process verification solutions, including those in the areas of sterilization, freeze drying, tunnel baking, and temperature measurement. freeze drying, tunnel ovens, pasteurization, warehouse temperature distribution verification, pasteurization and many other applications.

HK-TrackSense®Pro Wireless Authentication System

As a durable, intelligent, accurate and highly flexible system, the final configuration of a wireless data logger solution is achieved by combining the appropriate logger with selected interchangeable sensors. With a temperature range of -90°C to +150°C, the integrated sensors for ultra-low-temperature applications are compatible with most applications and are the most versatile choice.

HK-EVal™Pro Wired Authentication System

Provides a highly modern solution for wired verification. Small and lightweight, easy to maneuver in controlled environments, handles up to 40 thermocouples, large internal memory holds up to 10 checks at a time, features interchangeable sensor arrays that can be easily disassembled for maintenance and calibration, and complies with FDA regulations and GAMP guidelines.