Author: Cai Yongfu

Failure phenomenon

A 2015 Land Rover Freelander with a 2.2 L engine and approximately 160,000km has been reported by the owner as having a high speed cooling fan that does not stop when the vehicle is turned off.

Fault Diagnostics

After taking over the vehicle, first test drive, the fault phenomenon does exist. Using a fault detector, there is a permanent fault code “P0480-11 Fan 1 Control Circuit Shorted to Hitch” and an intermittent fault code “P0480-13 Fan 1 Control Circuit -Disconnect”. Try to use the fault detector to clear the fault code after the test drive, found that the fault remains, re-read the fault code, in the PCM is still stored in the fault code P0480-11.

Using a fault detector to read the cooling fan data flow, found that the engine coolant temperature of 74 ℃, cooling fan pulse width modulation control instructions for the 0%, indicating that the PCM did not give the cooling fan operating instructions, which can rule out the coolant temperature sensors, air conditioning pressure sensors and their wiring may be faulty.

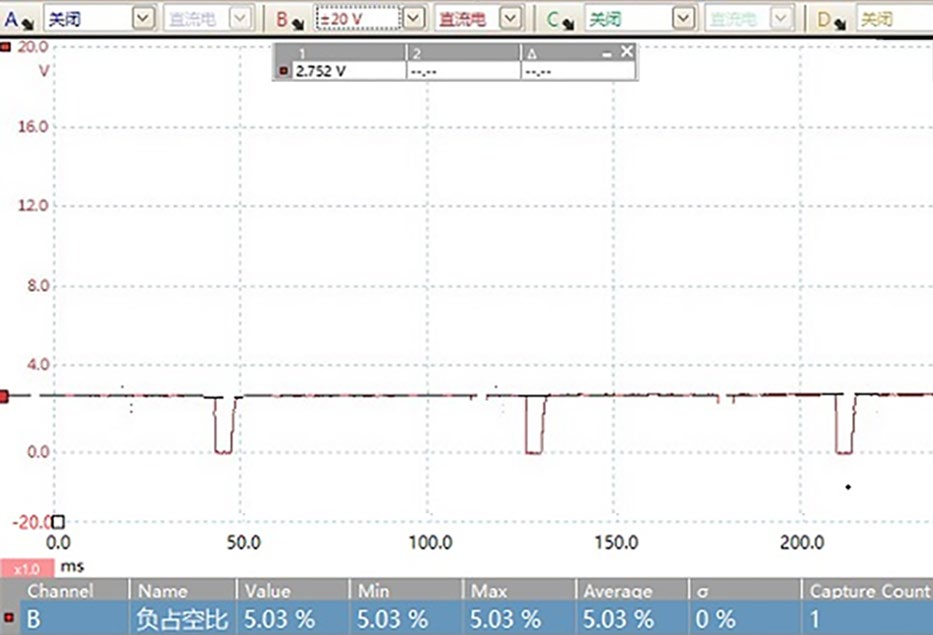

Check the maintenance manual, the cooling fan control module can receive the PCM 0% ~ 100% pulse width modulation frequency (PWM) signals, cooling fan control module according to the PWM signal to determine the output voltage of the two cooling fan motor, so as to regulate the speed of the cooling fan. According to the cooling fan control circuit (Figure 1), using a pico oscilloscope to measure the waveform of the PWM signal received by the cooling fan control module (Figure 2), it was found that the PWM signal received by the cooling fan control module has a high potential of 2.752 V, a low potential of 0 V, and a low-potential duty cycle of 5.031 TP3 T. After disconnecting the wire connector C1EC01A of the cooling fan control module, the following was measured There was no change in the waveform of the PWM signal from the PCM.

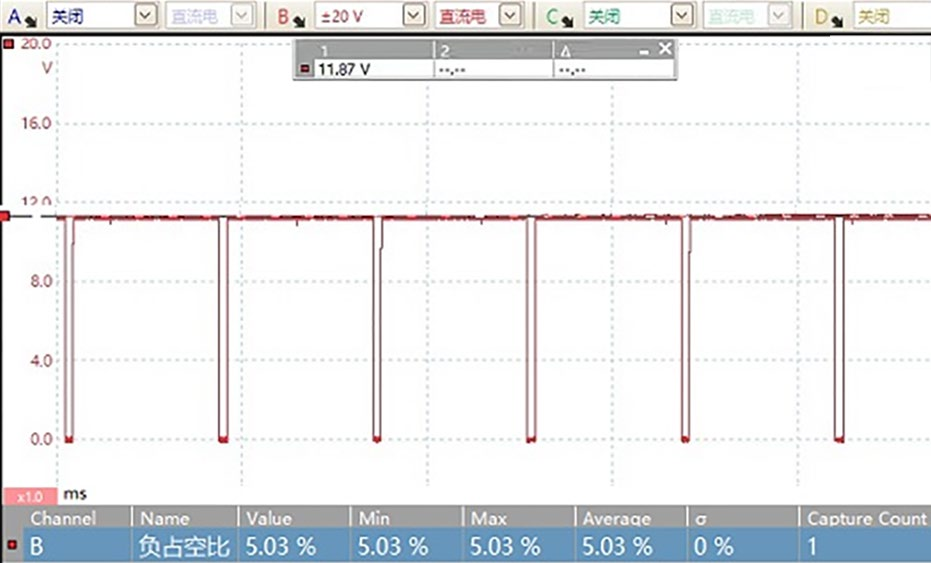

After clearing the fault code P0480-11 with a fault detector, the PWM signal from the PCM was re-measured to be 11.87 V at the high level, 0 V at the low level, and 5.03% at the low level duty cycle (Fig. 3). After installing the cooling fan control module wire connector C1EC01A, the fan is still running at high speed, and the PWM signal waveform received by the cooling fan control module is still as shown in Figure 2.

The radiator fan control module wire connector C1EC01A terminal 4 back pin, use the fault detector to clear the fault code P0480-11, and then again measured the radiator fan control module wire connector C1EC01A terminal 4 waveform for a 2.752 V straight line (Figure 4), measured the PWM signal waveform from the PCM as shown in Figure 3.

Compared to a normal car, the PWM signal from the PCM was measured to be 14.09 V at the high level, 0 V at the low level, and 5.031 TP3T at the low level duty cycle. After backing off the pin at terminal 4 of C1EC01A of the radiator fan control module lead connector, the waveform of the PWM signal from the PCM did not change, and the waveform of terminal 4 of C1EC01A of the radiator fan control module lead connector was measured to be The waveform of terminal 4 of C1EC01A of the cooling fan control module was measured as a 12.69 V straight line.

Through comparison, it is found that the faulty car in the radiator fan control module wire connector C1EC01A terminal 4 after backing out the needle, measured the radiator fan control module wire connector C1EC01A terminal 4 voltage is obviously low, which confirms that there is a signal circuit in the radiator fan control module to the iron short circuit, resulting in the emergence of the fault phenomenon.

fault resolution

Replace the cooling fan control module after several test drives, the fault phenomenon disappeared, so the problem is solved.

Fault Summary

The problem is caused by a short circuit in the signal circuit of the radiator fan control module, which prevents the fan from stopping after the engine is turned off.

After detecting and clearing the fault code through traditional thinking, the fault still could not be eliminated. Using a Pico oscilloscope to make several measurements on the cooling fan control module and compare it with a normal car, the cause of the problem was finally pinpointed on the position of wire connector C1EC01A terminal 4, and the problem was successfully solved.

Hong Hong Auto Repair Goodies

All of Pico's automotive oscilloscopes are designed to diagnose faults in any vehicle with an engine or motor, and can be used in a wide range of applications such as automobiles, ships, aircraft, construction machinery and stationary equipment such as large generators. They allow you to perform a wide range of routine tests including: sensors, actuators, relative compression tests and more.

If you have any questions, please feel free toContact Us!