Autonomous Driving Solutions

Mainly contains the German b-plus solution for recording, storing and converting vehicle data for analysis.

Data Conversion Analysis Tool - MDILink GMSL2/FPDLink Ⅲ/CSI-2

Data ingestion to data center or cloud replication - COPYLynx

BRICK 2

Product Features

high performance

Hexa-core Intel® Core™ i7-9850HE processor, 64GB memory, Intel® UHD graphics 630

Rugged and sophisticated design

Designed for harsh vehicle conditions and limited space.

Huge I/O bandwidth

6x 10 Gb Ethernet, 3x 1 Gb Ethernet, 4x USB3.1 Gen1

Time Synchronization

- Internal platform: all Ethernet interfaces are hardware-based time synchronization

- Cross-platform: Multi-domain time synchronization via IEEE 1588 802.1AS-2020

Storage Add-ons

- Removable Storage Units

- Write speeds up to 24 Gbit/s and capacities up to 32 TB

- Removable Storage Units

- Write speeds up to 32 Gbit/s and capacities up to 60 TB

Add to BMC

Each BRICK uses additional components for up to two measurement cards (BMC = BRICK Measurement Card).

BMC ETH 6000 - 6 Gigabit measurement card with time-synchronized Ethernet port and Ethernet power support

BMC VB2 - Flexible BRICK Measurement Card with 8 CAN FD or 4 CAN FD and 2FR

- Up to 2 cards in BRICK provide up to 16 CAN FD or CAN FD/FlexRay interfaces in different configurations.

- Modular concept with up to 4 bus modules

MDILink GMSL2

GMSL2 splitter

- 2x GMSL2 Connection Input (RX)

- 2x GMSL2 Connection Output (TX)

- Fully transparent TAP mode

- GMSL2 MAX9295A / MAX9296A SerDes

- Up to 2 10GbE download ports

- Coaxial cable power supply (external power supply)

GMSL2 4EP

- 4x GMSL2 Connection Input (RX)

- GMSL2 MAX9296A SerDes

- Dedicated deserializer for each port for maximum flexibility

- Up to 2 10GbE download ports

- Coaxial cable power supply (external power supply)

GMSL2STP

- 2 GMSL2 in Twisted Pair (RX)

- 2x GMSL2 Output Twisted Pair (TX)

- Fully transparent TAP mode

- GMSL2 MAX9295A / MAX9296A SerDes

- 2 10GbE download ports

- GND isolation connection

MDILink FPD-Link Ⅲ

Why choose FPD-Link III?

FPD-Link III is an interface designed for transferring high-resolution video data from cameras, radars and laser radars.

Combined with Power over Coax (PoC), it is ideally suited to the automotive environment. This eliminates the need for a separate unit for power supply, as the sensor draws power directly from the connected recording device. In addition, longer transmission distances can be realized compared to Power over Ethernet (PoE).

MDILink CSI-2

Why CSI-2?

The CSI-2 interface is typically used with camera sensors to provide a direct interface between the sensor and the ECU evaluation. The CSI-2 establishes a direct connection to the ECU so that image data can be transferred through the bus system without detours.

MDILink FPDLink III supports TSN IEEE1588 802.1AS-2020 standard, which enables high-precision time synchronization and time stamping in vehicles. As a result, we realize accurate and reliable transmission of high bandwidth from the ECU while maintaining data integrity at all times. With 10 Gbit Ethernet, we can ensure secure transmission without losing data - even over longer distances.

Solutions

AVETO.

On-board recording: Sensor raw data for recording camera lens, radar and laser radar data

For the development, testing and validation of ECUs and vehicle systems for driver assistance (ADAS) and autonomous driving, it is essential to collect data and realize real-world test drives.

The AVETO.recording function block provides a seamless and future-proof measurement solution for decoupling, transferring and recording raw sensor data from the sensor front-end to a data center or to the cloud.

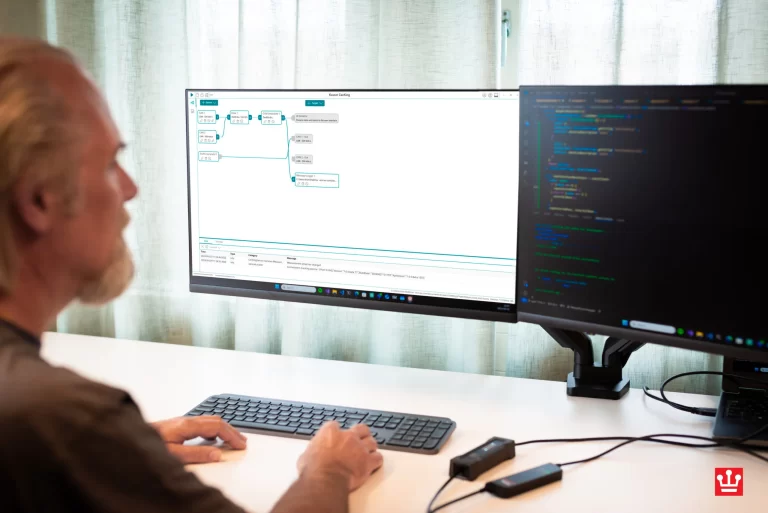

AVETO Analysis

Sensor Raw Data Analysis: An analysis tool for on-board use and visualization of sensor raw data.

The analysis and visualization of the sensor raw data is crucial for the development of ADAS/AD systems: it has many aspects and has been carried out both online during vehicle test drives and offline in the office, and further investigations have been carried out using the data recorded by the vehicle.

AVETO.analysis function blocks provide seamless and high-performance support from the first analysis, all the way through processing to testing.

In order to analyze the measurement data stream, it is necessary to use thePowerful software framework to visualize multi-gigabit sensors.AVETO visualization software enables this task, first in the vehicle for on-line inspection and then in the laboratory for more in-depth analysis. It can process hundreds of gigabytes of measurement data from multiple sensors. It can visualize lens data, bus data and even 3D point clouds, as is often the case with laser radars.

In order toFlexibility to extend your own visualizationThe framework provides an SDK for developing and integrating customer-specific visualizations.

DATALynx Vehicle Server

Our DATALynx series is designed to meet the difficult balance between performance and robustness in the testing and validation of sensor systems. It is designed for demanding in-vehicle applications while delivering the superior performance expected from data centers.

We bring the world together and unleash the power on the road with the DATALynx collection.

Data collection platform

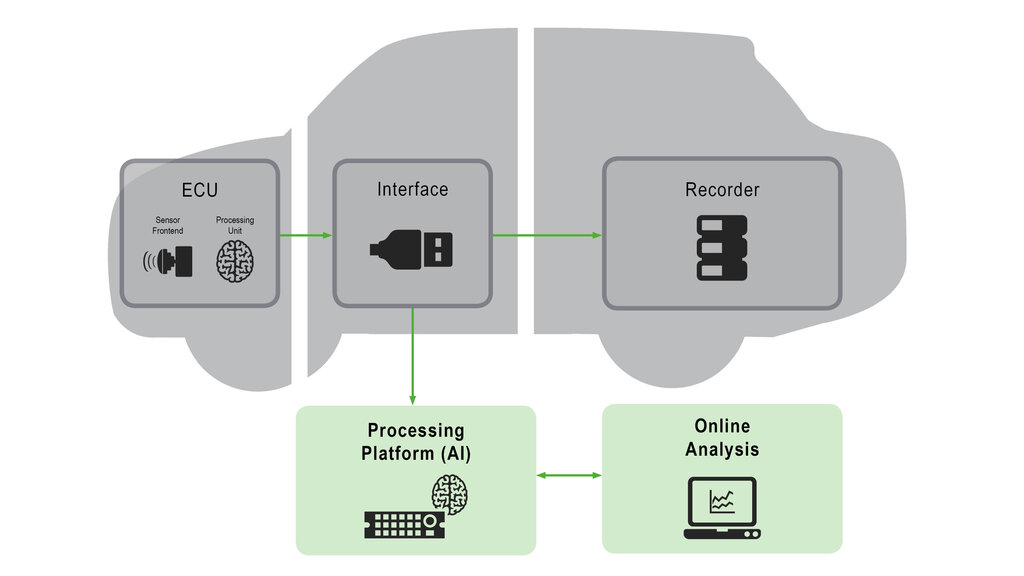

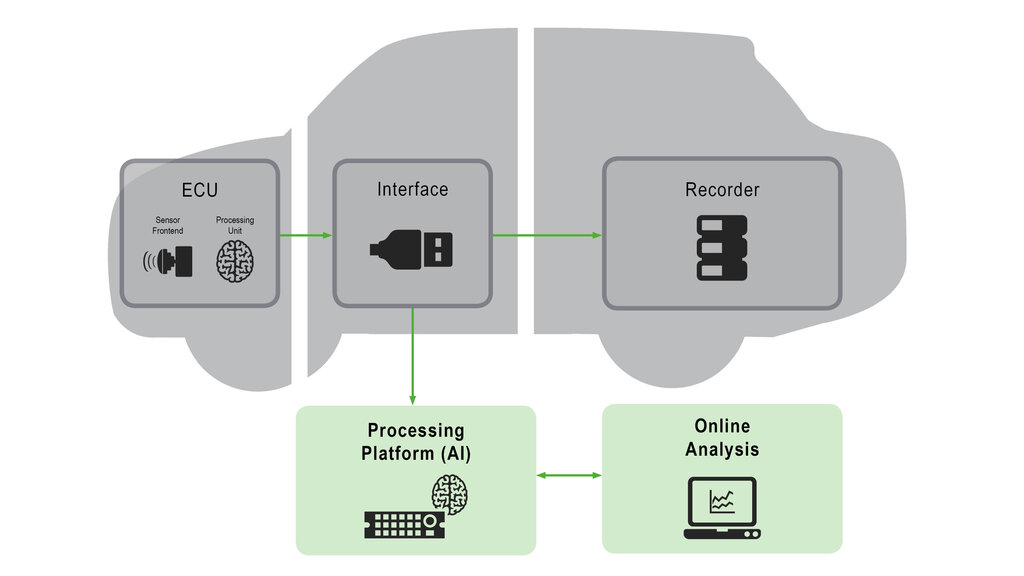

Data collection from multiple sensor data streams is a typical task during vehicle sensor development. This is a simplified example of how to use DATALynx aggregation to process multiple source data streams simultaneously.

Data Processing Platform

In the first step of developing a sensor-based system, it is often necessary to prototype the algorithms and process the images. Another task is to pre-label and filter the scene in real time during the test drive. See below for a simplified setup for online analysis and processing.

DATALynx Vehicle Server

Our DATALynx series is designed to meet the difficult balance between performance and robustness in the testing and validation of sensor systems. It is designed for demanding in-vehicle applications while delivering the superior performance expected from data centers.

We bring the world together and unleash the power on the road with the DATALynx collection.

Data collection platform

Data collection from multiple sensor data streams is a typical task during vehicle sensor development. This is a simplified example of how to use DATALynx aggregation to process multiple source data streams simultaneously.

Data Processing Platform

In the first step of developing a sensor-based system, it is often necessary to prototype the algorithms and process the images. Another task is to pre-label and filter the scene in real time during the test drive. See below for a simplified setup for online analysis and processing.

Automotive Electronics Case Study

All automotive electronics test solutions can be found here!