I. Background and Challenges of Cooperation

Founded in Germany, the JUNKER Group is a global leader in the field of machine tools. The company specializes in the development, production and sale of high-precision grinding machines and industrial air filtration equipment for metal processing.While providing standardized equipment, they also focus on providing customized solutions, technical consultation and comprehensive after-sales service.

Because of its precision and heavy weight, grinding machine equipment is often exported to third-party countries, where it is often subjected to long sea voyages, temperature fluctuations and bumpy transportation.Prolonged sea transportation and temperature fluctuations can lead to invisible damage to the equipment, which in turn can affect accuracy or cause malfunctions. To ensure safety during transportation, the JUNKER Group was looking for a modern monitoring solution, especially for the real-time monitoring of shock events and temperature fluctuations in grinding machine equipment.

Picture 1: JUNKER's grinding machine equipment.

Practical application

01 Reliability Assessment:

Before deciding to adopt the Honghong ASPION G-Log impact recorder in volume, the JUNKER Group's transportation team conducted several rounds of impact tests using a prototype. The technicians evaluated the equipment's impact resistance by comparing it to actual transportation situations, such as hanging weights on a crane to simulate a load.The test results showed that the equipment was able to effectively record and provide feedback on critical impact events, which is critical to transportation safety.

Subsequently, the field technicians completed the deployment and commissioning of the ASPION G-Log loggers during a major equipment transportation project. Each time the grinding machine system is transported, two loggers are used: one is mounted directly on the grinding machine and its add-ons, and the other is mounted via a bracket on the control cabinet or filter system, thus enabling full monitoring.

02 Intuitive ease of use:

In addition to its outstanding technical performance, the ASPION G-Log Impact Recorder is also notable for its ease of use. The device supports operation via PC software and mobile APP. Users can quickly configure the logger with NFC technology and instantly view and analyze the data during transportation via the mobile APP.This intuitive operation greatly shortens the learning curve and improves work efficiency.

According to the logistics and transportation team, the easy-to-understand operation of the computer software enables technicians to quickly configure the parameters of the EDRD, while the mobile phone APP facilitates the destination assemblers to quickly read and share the data.This not only helps to generate clear transportation reports, but also provides strong data support for insurance claims.

Customers have also found that the NFC capability enables assemblers around the world to easily upload stored data from the logger to the transportation team.Ensure that information is delivered efficiently and accurately.

03 Wide applicability:

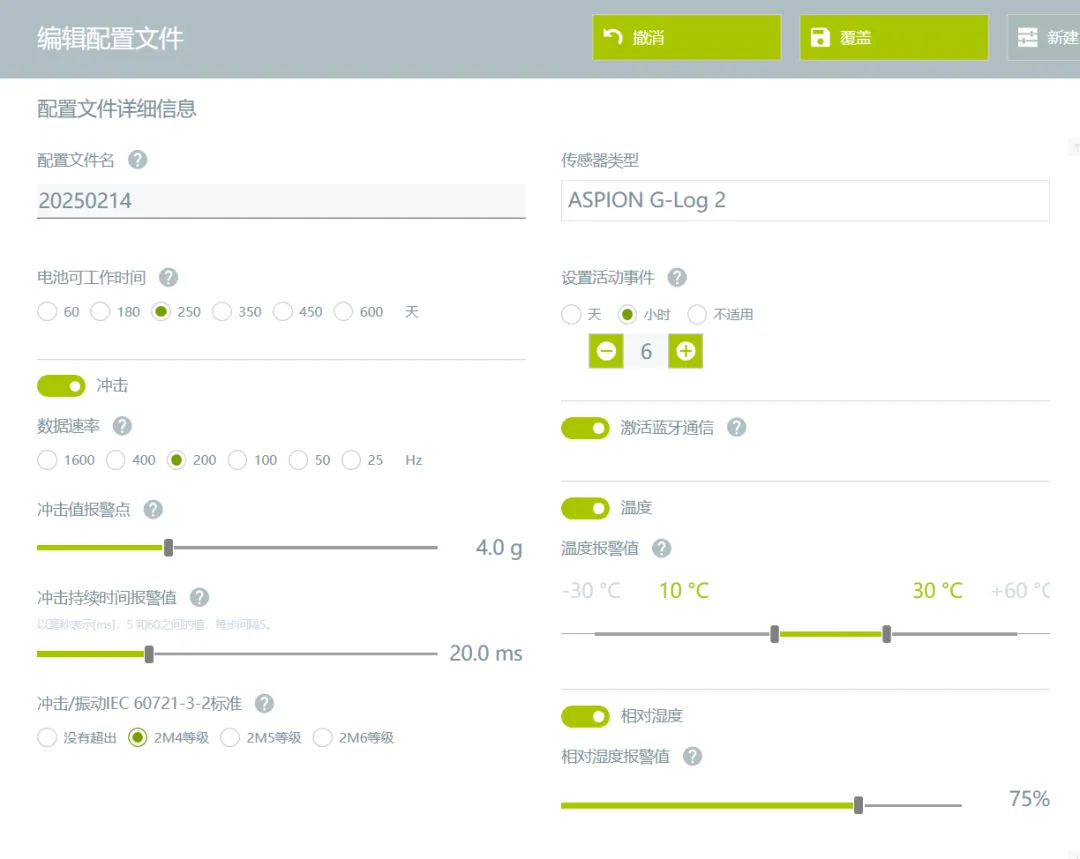

The ASPION G-Log is not only suitable for sea, air and land transportation, but also for complex intermodal situations. The preset parameters of the device can be fully customized to meet the specific needs of each type of equipment.The JUNKER Group creates a dedicated profile for each type of grinding machine, enabling precise monitoring.

In addition, the device supports customized settings such as impact strength, duration, and temperature and humidity thresholds.Simply selecting the appropriate profile and uploading it to the recorder simplifies the operation process and improves the overall monitoring performance.

Figure 4. Freely Defined Monitoring Thresholds for Shock, Temperature and Humidity

Case Summaries

By using Honghong's ASPION G-Log impact recorder, JUNKER Group has successfully achieved the following transportation monitoring goals:

Accurate records:The time-stamping function of the EDRD can clearly identify the time and location of each abnormal event in the transportation process, thus facilitating the assignment of responsibility and the tracking of problems.

Multiple monitoring:In addition to impact monitoring, the ASPION G-Log recorder can also monitor temperature and humidity changes in real time to ensure the safety of equipment during transportation.

Easy Assessment and Reporting:Transportation reports generated via PC or mobile app can be quickly sent to the relevant parties to ensure that any transportation damage can be identified and used as the basis for insurance claims in a timely manner.

Figure 5: ASPION G-Log Data Display Interface

Product Recommendation

ASPION G-Log Shock Sensor

- Real-time monitoring:Accurately records every impact event during transportation.

- Quick Configuration:Supports NFC technology, making the configuration process simple and intuitive.

- Multi-mode applicable:Suitable for sea, air, land and intermodal transportation.

- High precision records:Ensure the accuracy of data for each transportation and safeguard the safety of the equipment.

ASPION G-Log 2 Transportation Data Logger

- Multi-sensory integration:Integrate more sensors to provide high-level computing power.

- Highly accurate monitoring:Precise impact monitoring for oversized or complex transportation scenarios.

- Customized alarms:Customizable alarm thresholds and notification methods to enhance transportation safety.

- Data visualization:Seamless connectivity with Trusted Data Portal for at-a-glance analytics reporting.