Author: Shandong Jinan Lu Guoqiang

Failure phenomenon:

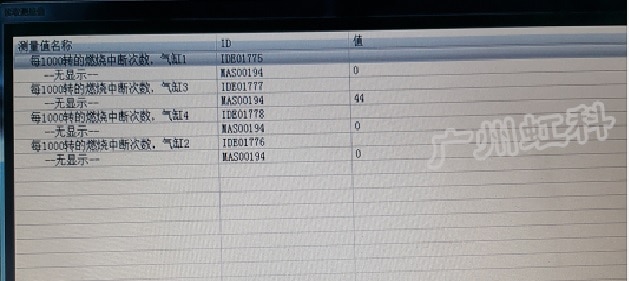

Customers to buy this used car, mileage 110,000 kilometers, the vehicle took over the engine idling jitter, the customer himself using OBD diagnostic equipment to read the engine data flow per 1,000 rpm combustion interruptions in the cumulative number of three-cylinder misfire data, but the engine fault light is not lit, the engine does not have any fault code.

Repair history:

Customers in the local workshop and the original factory because of this problem replaced the engine high-pressure oil pump, fuel injector, gasoline filter, spark plugs, ignition coil, cleaned the throttle, intake valve carbon, carbon deposits in the cylinder and other repair work failure has not been eliminated but the vehicle acceleration performance has been improved, introduced by a friend to the store to find the author of the maintenance.

Troubleshooting:

1. test engine idling jitter, the exhaust pipe transmitted “mutter” sound, the engine is obviously a cylinder is not working well. Use ODIS to read the engine fault code does not have the relevant fault code, read the engine misfire data stream, the number of combustion interruptions per 1000 rpm in the data stream in the three cylinders combustion data frequency with the engine running continuously accumulated, the other three cylinders misfire data for 0. Description of the three cylinders there is combustion interruption of the work of the failure, but not every combustion will be interrupted.

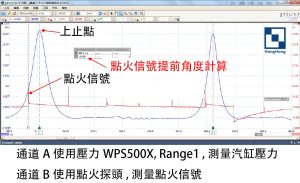

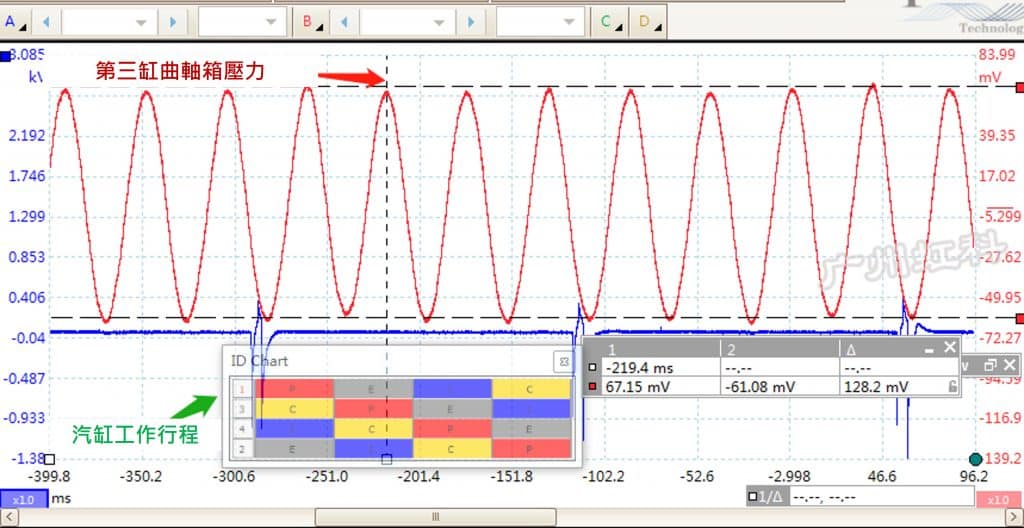

2. In order to confirm that the third cylinder is indeed not working properly, the WPS500X Pressure Sensor was used to measure the exhaust pulse and the test results are shown below.

3. From the exhaust pulse and the ignition signal of the third cylinder, it can be confirmed that there is a misfire in the third cylinder.

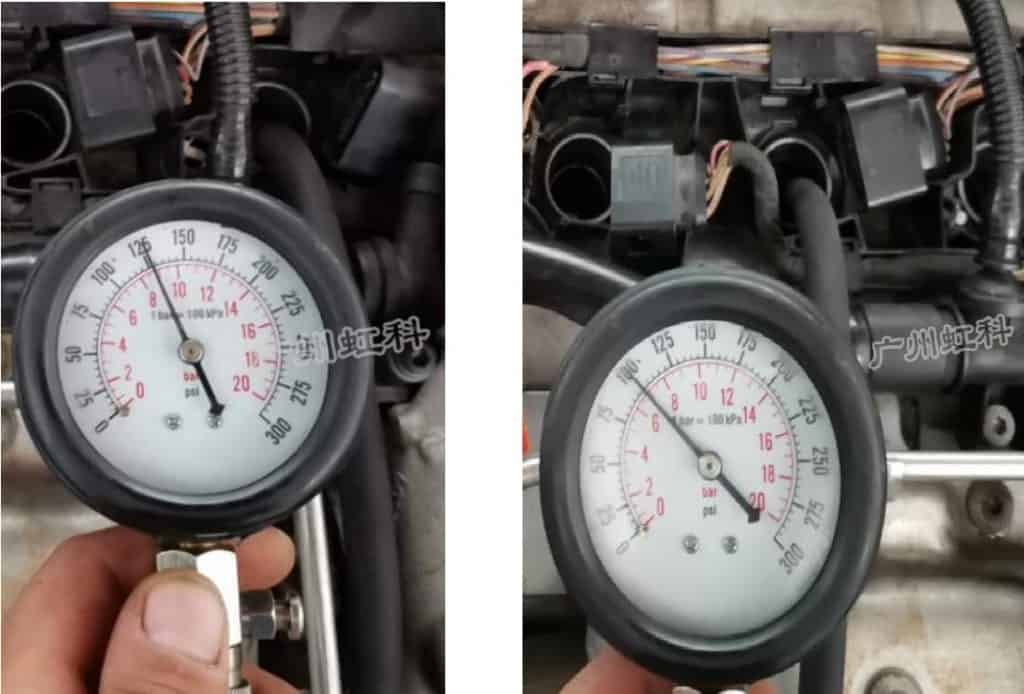

4. Use a cylinder pressure gauge to measure the cylinder pressure of 4 cylinders, 8.5 bar for cylinder 1, 9 bar for cylinder 2, 7 bar for cylinder 3, and 9 bar for cylinder 4.

Note: Mechanical cylinder pressure gauge readings for the cumulative cylinder pressure, because the cylinder pressure gauge piping structure has a one-way valve, the pressure can only be transferred from the cylinder to the cylinder pressure gauge head direction, each time the compression will overcome the piping pressure to the pressure gauge head to transfer the pressure, case after the use of the PICO WPS 500X pressure sensor to test the pressure of the cylinder because the PICO WPS500X pressure sensor structure does not have a one-way valve, the test pressure data for the cylinder each time the compression pressure, there will be a difference which is normal. Because there is no check valve in the structure of the PICO WPS500X pressure sensor, the pressure data of the test is the pressure of the cylinder each time it is compressed, and it is normal that there will be a difference.

According to the test results, we calculated that the average pressure of the three cylinders without misfire data in 8.8bar = (8.8 + 9 + 9) ÷ 3, for a normal gasoline engine pressure difference between the cylinders can not be greater than 8%, the calculated value of 8.8 × 8% = 0.7ba, with the average value and the three cylinders of the compression pressure for comparison 8.8-0.7 = 8.1bar, the third cylinder The cylinder pressure of 7 bar is lower than the average cylinder pressure value of 1.1 bar.

5. Based on the test results, it is determined that there is insufficient compression pressure in all three cylinders, but whether this is caused by insufficient air intake or poor cylinder sealing requires further inspection. Use the Cylinder Leak Tester to check the leakage of each cylinder of the engine, and compare the leakage data of the normal cylinder with that of the abnormal cylinder.

The leakage of the three cylinders reached 15% or more, four cylinders of the leakage of only 1%, indicating that there is a serious cylinder sealing problem in the three cylinders, gasoline engine standard leakage of 10% or less, the author of the high value is the data of the early vehicle engine, can not be used as a basis for the judgment of the maintenance failure. However, by comparing the leakage of other cylinders of this car is 1%, which indicates that the leakage of three cylinders seriously exceeds the standard, and according to the test results, it is not due to the problem of insufficient intake caused by the low compression pressure, but due to the cylinder sealing leakage caused by the cylinder compression pressure is too low.

Cylinder sealing abnormalities may occur as follows:

- The intake and exhaust valves do not seal properly;

- Piston rings are stuck or mated;

- Cracked piston ring;

- One end of the piston is cracked;

- Cylinder bed gasket is not sealed properly;

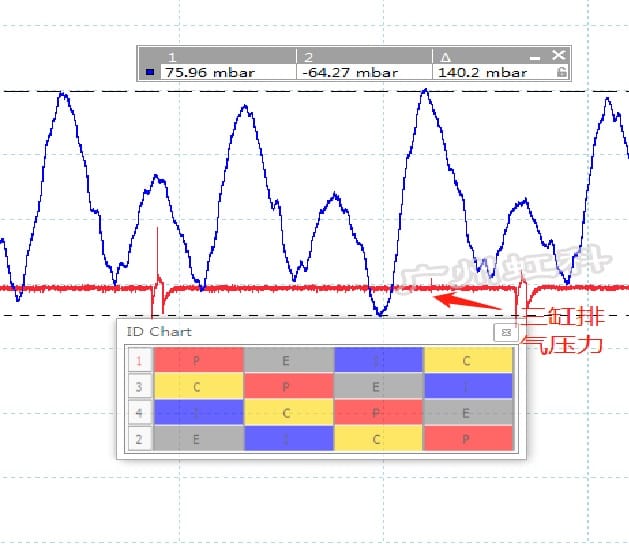

6. Measure crankcase pressure to determine if piston ring or piston leakage is causing cylinder sealing problems, start the vehicle and use the WPS500X to measure crankcase pressure.

7. From the crankcase pressure waveform, it can be seen that the leakage of each cylinder to the crankcase is the same, and there is no significant increase in the crankcase pressure during the three-cylinder power stroke, so it is judged that the leakage of the cylinders is not in the piston rings or pistons.

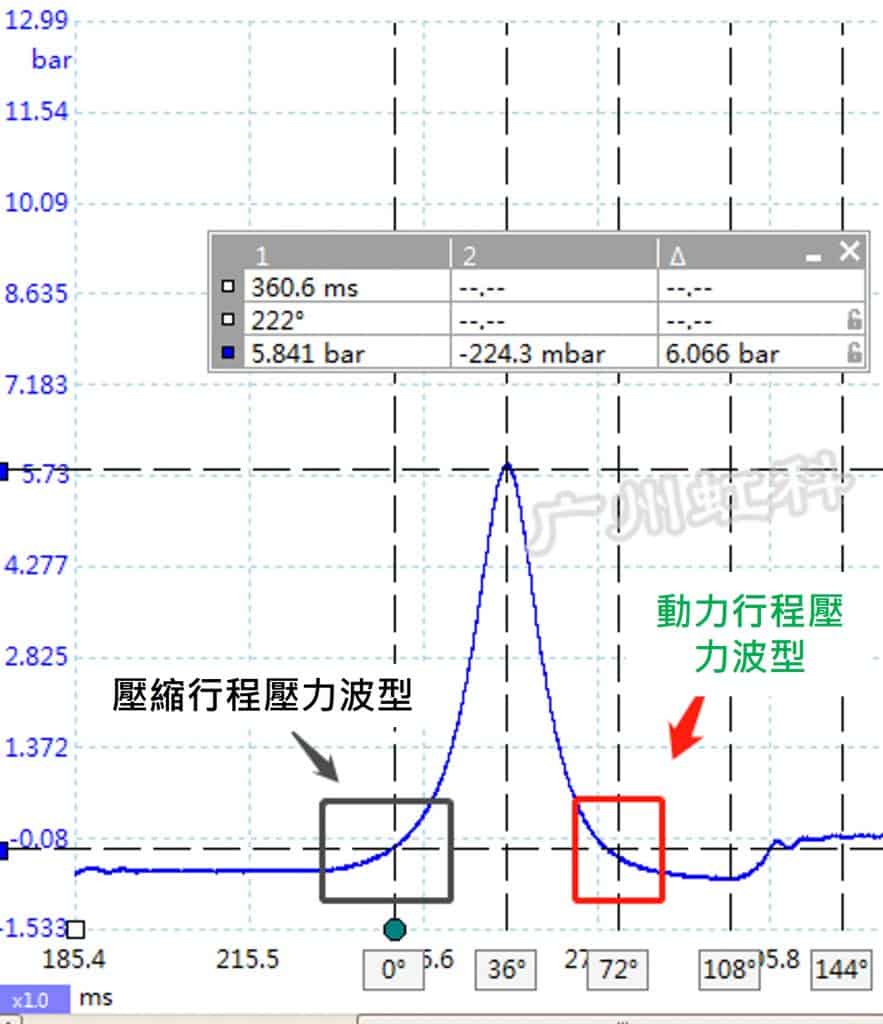

8. Measure the cylinder pressure waveform during operation of the third cylinder.

9. The compression pressure of the third cylinder is 5.84 bar, which is the difference between the electronic pressure sensor and the mechanical cylinder pressure gauge. From the change of the pressure waveform of the three cylinders, it can be seen that the pressure drop curve at the end of the power stroke is steeper than that of the compression stroke, and that the pressure curve in the cylinder of a normal engine is symmetric regardless of whether it is the compression stroke pressure waveform or the power stroke pressure waveform on both sides, so it is judged that the leakage of the third cylinder has caused the low compression pressure. Therefore, it is determined that the third cylinder is leaking, resulting in low compression pressure.

Note: Because the cylinder is not really working when using WPS500X to test the cylinder pressure waveform, the power stroke is changed to the release stroke of the compression pressure, so there is no sudden change of the ignition pressure, this test parameter can accurately determine the timing angle of the engine and the working condition of the mechanical parts.

10. With the customer's consent to dismantle the engine, it was finally determined that the point of failure was the exhaust valve of the three cylinders was corroded, resulting in the sealing surface of the valve sealing surface of the cylinder head and the sealing surface of the valve seat sealing surface sealing leakage caused by a decrease in the compression pressure of the cylinder.

Diagnostic Conclusion:

This fault diagnosis process uses a variety of equipment for fault determination, some maintenance peers would say cumbersome, in fact, before disassembling the comprehensive test is to improve the accuracy of fault diagnosis, because after disassembling to find the fault is not time-consuming and laborious, now the fault diagnosis is the need for systematic basic theoretical knowledge + diagnostic ideas + detection tools + maintenance experience, which is insufficient to increase the fault judgment The difficulty of fault judgment will be increased if any one of the links is insufficient.

The misfire data of an engine is based on the acceleration of the crankshaft per unit of time during the ignition power stroke of the cylinder, i.e., the angle of rotation. If the cylinder is working well, the acceleration of the crankshaft is high during the power stroke, and the angle of the crankshaft turned is large, and vice versa, there is an engine misfire. Therefore, the engine computer logically calculates according to the crankshaft position signal and ignition signal, and counts the misfires of each cylinder, and only when a certain number of misfires are reached in a unit of time, will the engine misfire fault code be stored and the engine malfunction light be illuminated. It reminds the driver that the vehicle is in trouble and should be repaired in time.