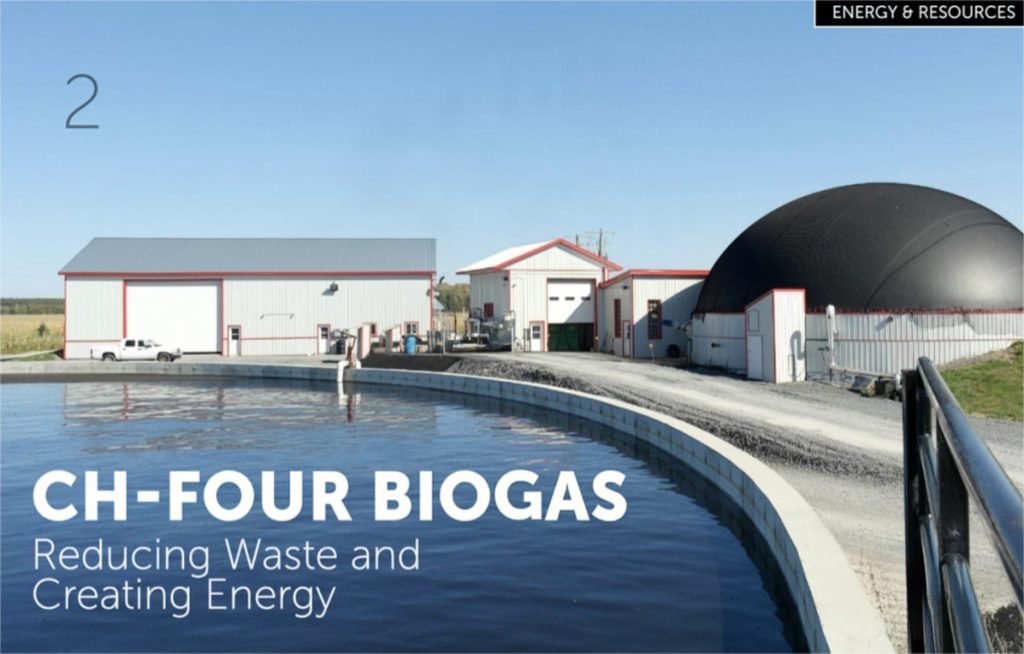

Case Introduction

CH Four Biogas, a design and consulting firm, has successfully introduced Swiss biogas technology to the North American market and has incorporated advanced anaerobic digestion technology into their projects. The company specializes in the development of anaerobic digestion and biogas facilities, including technology studies, system engineering and design, construction management, and system optimization. With the impact of the epidemic, many companies have had to look for alternative ways to accomplish tasks that used to require travel. Recently, CH Four Biogas turned to augmented reality smart glasses to support remote factory inspections. They have found that this solution not only provides a cost-effective way to avoid traveling, but has also been a key factor in supporting the company's expansion in North America.

On-site inspections constrain business development

CH Four's biogas plant construction business requires frequent inspections and tracking throughout the construction process to ensure compliance and respond to potential emergencies.

Prior to the outbreak, the company traveled to specific project sites on average four to five times per quarter for inspections, mostly between the U.S. and Canada. Since these projects were often located in rural or remote areas, the site visits took 3-5 days and involved travel costs. The high cost of on-site inspections severely limited the company's growth.

Remote support, inspection and commissioning

In a typical installation project, which takes 2-3 years, construction takes up 6-12 months. Throughout the construction cycle, engineers need to be on site to audit the building. With the Vuzix M400 smart glasses and mobile WIFI hotspots, high-cost on-site inspections can now be conducted remotely, enabling operators to utilize “what you see is what you get” technology to allow remote inspectors, often hundreds of kilometers away, to conduct accurate and efficient audits. Considering that critical milestones are often controlled during the inspection phase, smart glasses provide a level of security that ensures that the work is carried out even during high-risk periods. engineers at CH Four Biogas have equipped field managers with Vuzix M400 smart glasses, which enable them to carry out inspections, debugging and troubleshooting remotely.

“Describing things over the phone or via email often doesn't convey information accurately; we need to see what's going on in real time, and we need to make sure that there are things on site that need attention. That's a task that design engineers have to do themselves because they know the design best. The ”WYSIWYG” feature of smart glasses means that engineers have a pair of ’eyes” in the field. So the Vuzix smart glasses are the solution we need to keep our projects moving forward." said Lapointe, Vice President of Engineering at CH Four Biogas.

Reduced travel costs

During the outbreak, CH Four Biogas, which had to make frequent visits to its workplace, traveling for hours or even a week, realized significant time and cost savings from the Vuzix solution. During the outbreak, Vuzix helped the company save $70,000 for travel expenses In addition, the company is now able to make better use of the time of its senior engineers. Additionally, the company is now able to better utilize the time of its senior engineers: by placing Vuzix M400 Smart Glasses at various remote sites and having a construction manager on-site, a senior engineer can remotely inspect projects spread across North America in a single day. “From here on out, we can support more projects at the same time, better utilize our engineering staff and take on more work.” Lapointe said.

In addition to keeping the project on track and troubleshooting remotely, Vuzix's solution offers cost savings: Normally, the customer pays for the travel of CH Four's engineers to the site for inspections. By eliminating the need for engineers to be physically present on site, the customer was also able to save costs.

CH Four's forward-looking approach

Remote plant inspections using Vuzix smart eyewear solutions are just the beginning for CH Four Biogas. By saving time and travel costs, the company is able to expand its strategic commitment to its North American operations while reducing the need to send inspectors to remote facilities, thereby reducing carbon emissions and contributing to the global ecosystem.

“Vuzix allows us to work in multiple locations simultaneously, greatly expanding the scope of our team's capabilities. All of this helps us better support our partners, which is our top priority.” Lapointe said.

It is certain that from technology to products, the augmented reality glasses industry is embracing the opportunity to lead the world, and Vuzix is expected to become the core force driving the development of the global augmented reality glasses industry and remote engineering.

If you have any questions, please feel free toContact Us!