Honghong will provide you with any support you need!

Our professional Honghong team will be the first to respond and provide you with the best service to solve all your problems.

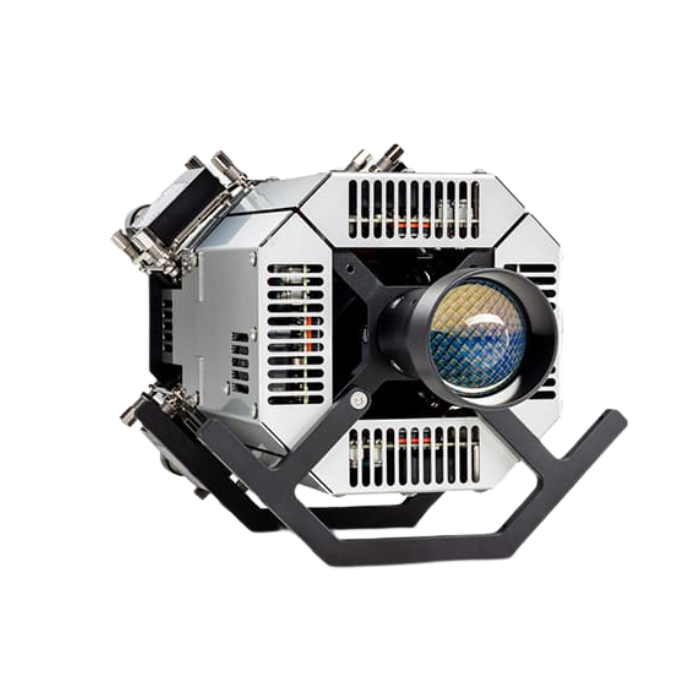

Honghong Semiconductor Lithography Light Source Solution

Easy mask lithography exposure based on Macrohon's high power ALE series UV LED light source

High-power UV LED lithography light source for large substrates, environmentally friendly alternative to high-power mercury lamps, efficiently retrofitting UV lithography equipment

Highly flexible, easy setup integration, single or multiple wavelength output configurations available, full control of broadband exposure spectrum in the 350-450nm range, high resolution down to 1μm/submicron range

Maximum output power up to 80W, consistent UV output over long periods of time, long operating life and cost advantages, no additional cooling time required

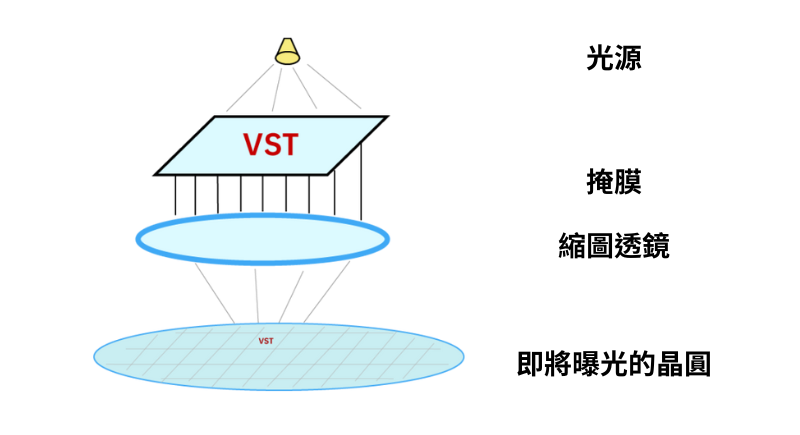

UV lithography and exposure are the core technologies used by the semiconductor industry to produce a variety of high-end wafers and microscopic circuit structures. In the UV lithography process, ultraviolet light emitted from a light source is passed through a tiny lens or grating on a mask and then projected onto a photoresist layer to form the desired micro-pattern.

For a long time, the semiconductor manufacturing field has used traditional high-power mercury lamps as the UV light source for lithography equipment. UV LEDs, with their unique technological and cost advantages, provide an ideal solution for the semiconductor manufacturing sector, as they can deliver stable, ultra-high-power UV radiation with a guaranteed long time and long operating life.

Due to the unique advantages of UVLEDs, more and more research laboratories are using UVLED light sources to replace traditional mercury light boxes. However, the replacement of equipment is not a simple “key to open the door” process, need to consider the replacement cost, equipment volume and equipment compatibility, and more critical to ensure the stability of the exposure effect.

Honghong UVLED UV light source provides stable and ultra-high power UV radiation output with single peak (365 nm) or dual peak wavelength (365/405 nm and 405/435 nm) output configurations up to 80 W. It offers long life and cost advantages, no additional cooling time, ready-to-use, replaces traditional light box construction, and eliminates the need for a main beam folding mirror, It replaces traditional light box configurations and eliminates the need for main beam folding mirrors, heat sinks to absorb radiation in excess of 450 nm under shutter and filter components.

(Schematic diagram of UV lithography exposure process)

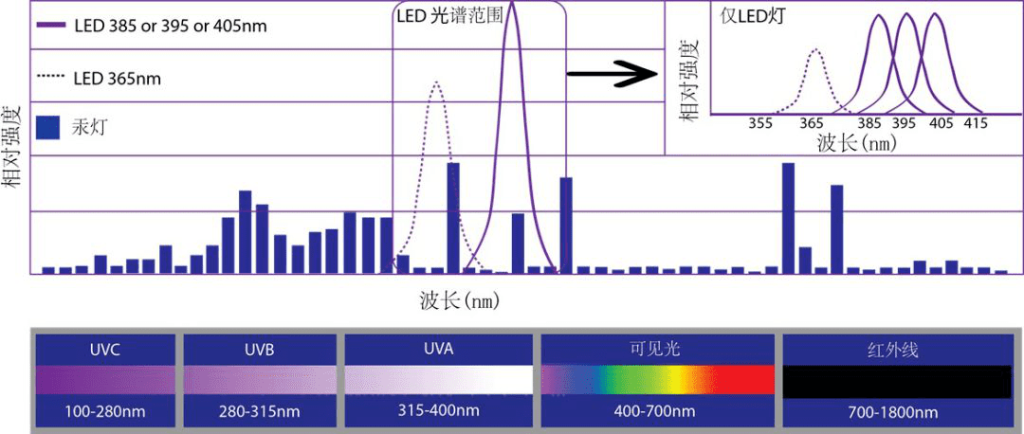

(UV LED spectrum)

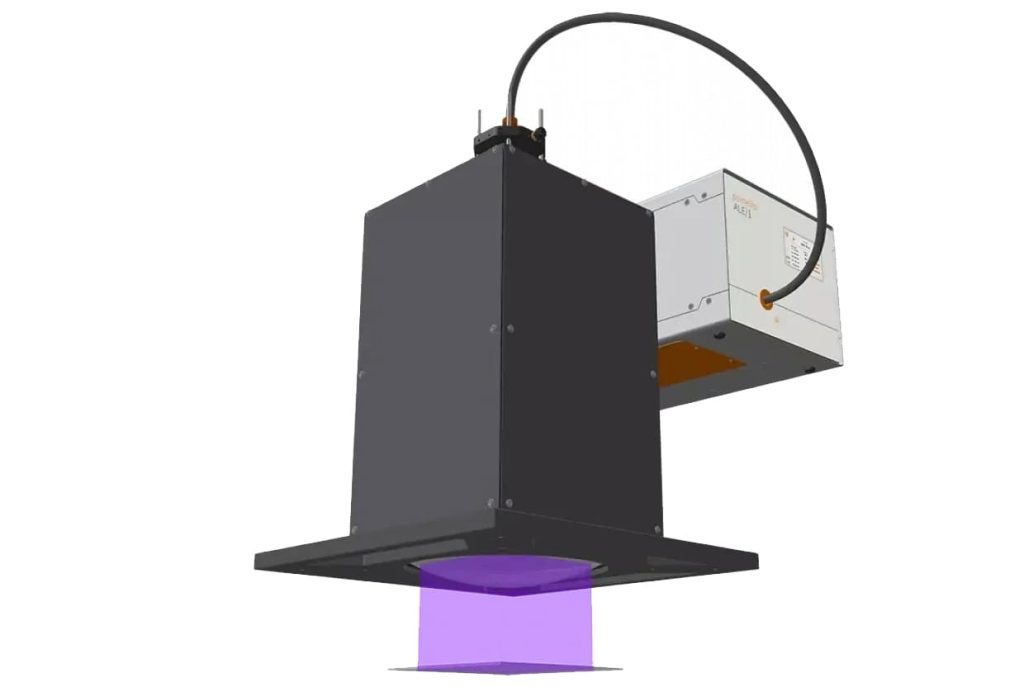

Honghong (brand) ALE high power UVLED The combination of a light source and collimated flood exposure optics not only upgrades the traditional mask collimator light box to the UVLED The versatility and flexibility of the technology is also more affordable.

Honghong UVLEDs are configured with 4 UV wavelengths, 365, 385, 405 and 435nm, allowing at least 1 and up to 5 wavelengths to be selected to satisfy a wide range of testing needs.

Honghong's ALE UV light source is a safer alternative to traditional mercury lamps in research laboratories because it does not contain mercury. Mercury is harmful to human health and the environment, and traditional mercury lamps pose a potential exposure risk

ALE UV light sources consume less energy than traditional mercury lamps. Not only does this help reduce energy bills in the long run, but it also makes UVLEDs a better choice for laboratories that are trying to reduce their carbon footprint.

ALE UV sources have a longer life than traditional mercury lamps, meaning they require less frequent replacement and maintenance, saving laboratories money.

ALE provides consistent UV output over time without the need to adjust lamp intensity or change lamps frequently, ensuring greater accuracy and reducing the risk of errors due to uneven illumination.

The ALE can be perfectly integrated into modern laboratory setups. The fully adjustable output spectrum and advanced control interface are designed for advanced exposure experiments and make it easy to collect data and analyze results.

|

Backend lithography applications in the semiconductor, MEMS, LED wafer, power device and microfluidic industries utilize a wide variety of mask alignment systems. Manual, semi-automatic and fully automatic mask aligner systems are available to meet the requirements of any production environment. Macronix UVLED UV source solutions (ALE/1, ALE/1C and ALE/2) have been successfully integrated into a variety of mask alignment systems, producing excellent results in contact exposure, projection exposure applications, and are now seeing excellent uniformity, collimation (<2°), high resolution down to 0.7μm and high surface radiation power. |

| 2. Broadband stepping systemWideband stepper systems play a crucial role in advanced packaging applications such as Fan-Out Wafer-Level Packaging (FOWLP), Wafer-Level Chip-Scale Packaging (WLCSP) or Through-Silicon Vias (TSV). complex microstructures, such as MEMS or LEDs, are important examples of what can be manufactured on highly specialized stepper devices. By combining individual LED modules around the i-, h- and g-lines into a single light path, the MAXTRON Broadband ALE Source provides complete control over the spectral composition of broadband exposures in the 350-450nm range, achieving resolutions down to 1μm or even sub-micron, and delivering higher radiation output. Honghong UV light source solutions offer the flexibility to choose the photosensitive advanced packaging materials that may be required in the process, replacing any conventional high power mercury arc lamps even above 1kW, providing superior system throughput. |

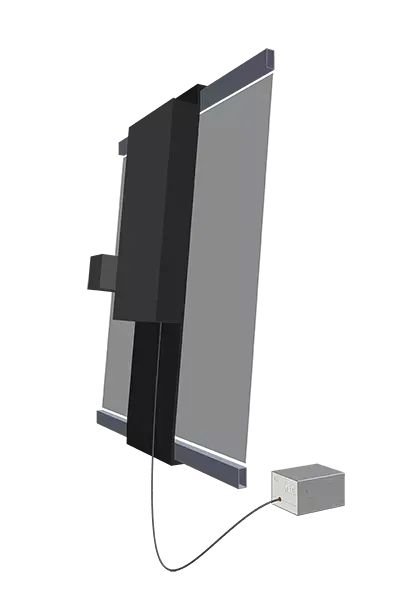

| 3. Collimated Exposure System Mask aligners and steppers create layer after layer of precisely positioned and structured patterns to fabricate complex integrated circuits, compound semiconductors and other microelectronic devices. Many UV-curable applications require exposures as precise as semiconductor production, but do not require multiple lithographic steps with carefully aligned microscopic structured layers. Collimated UV light source exposure is preferred for this application. Macronix UV light source solutions can be integrated into applications that require UV flood exposure, and the modular product line allows you to select all components to meet the exposure requirements. |

| 4. Photomask Detection A perfect photomask or photomask is an important reason for high throughput in photolithography applications. Defects and contamination can lead to pattern placement errors that are repeated on the production substrate. A photomask inspection system helps the shop identify its photomasks and wafers, safeguarding yield by reducing the risk of printing defective wafers and other substrates.

Integrating Macronix UVLED technology into a photomask inspection system for large photomasks allows the quality of incoming photomasks to be assessed and the markers to be recertified at regular intervals during the production process. The solution has three major advantages: |

|

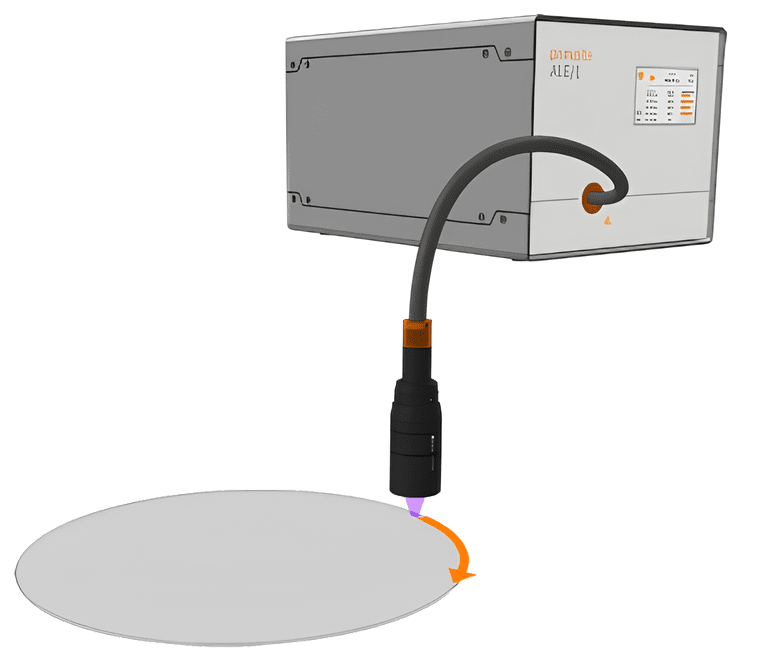

5.WEE Wafer Edge Exposure Click to enter: Honghong WEE Wafer Edge Exposure UVLED Light Source Solution |

With a light output of up to 30W, the mercury-free design combines the radiant power and spectral characteristics of a mercury discharge lamp with the process advantages of LED technology.

Based on a modular platform, the system can combine up to five high-performance LEDs in the light path, providing flexible spectral composition and customized solutions. The light source is available in UV Curing Applications It is a perfect replacement for traditional 200W mercury lamps for spot curing operations in high volume production, providing more efficient energy conversion and application flexibility.

With up to 15W of light output, LED industrial stability and TCO advantages, it can be easily integrated into new and old setups.

This light source supports multiple wavelength curing modes, allowing exposure at high wavelengths and high intensity curing at low wavelengths, resulting in a fully cured adhesive layer and a smooth, perfect surface. It is available in UV Curing Applications Ideal as a replacement for traditional 200W mercury lamps, it provides efficient and consistent curing results.

Macrohon ALE/1C UV exposure system, combining up to 3 UV-LED emitters, provides narrowband and broadband UV radiation output in the range of 350-450 nm.

The total output power is up to 40 W and up to 50 W with an external cooler, making it a perfect replacement for high power mercury lamps. The system follows a decentralized design approach and is compact enough for industrial integration.

Honghong ALE/2 UV exposure system provides narrowband and broadband UV radiation output in the range of 350-450nm; narrowband output power up to 70W, broadband output power up to 80W, completely replacing high-power discharge mercury lamps.

Decentralized design, consisting of a control subsystem (CSS) and one or more independent exposure subsystems (ESS), very compact structure for industrial integration.

Our professional Honghong team will be the first to respond and provide you with the best service to solve all your problems.

Address: 3F, No. 99, Jingye 1st Road, Zhongshan District, Taipei City, Taiwan (Da Wan Technology Center Building)

3rd Floor., Dawan Technology Center Building, No. 99 Jingye 1st Road, Zhongshan District, Taipei City, Taiwan

©2025.hongtronics. All Rights Reserved.