Honghong will provide you with any support you need!

Our professional Honghong team will be the first to respond and provide you with the best service to solve all your problems.

Honghong Automatic Tunable Light Source Filter Performance Test Solution

Fully automatic adjustment of the output wavelength and bandwidth of the test light source to improve the accuracy and efficiency of the optical filter inspection process.

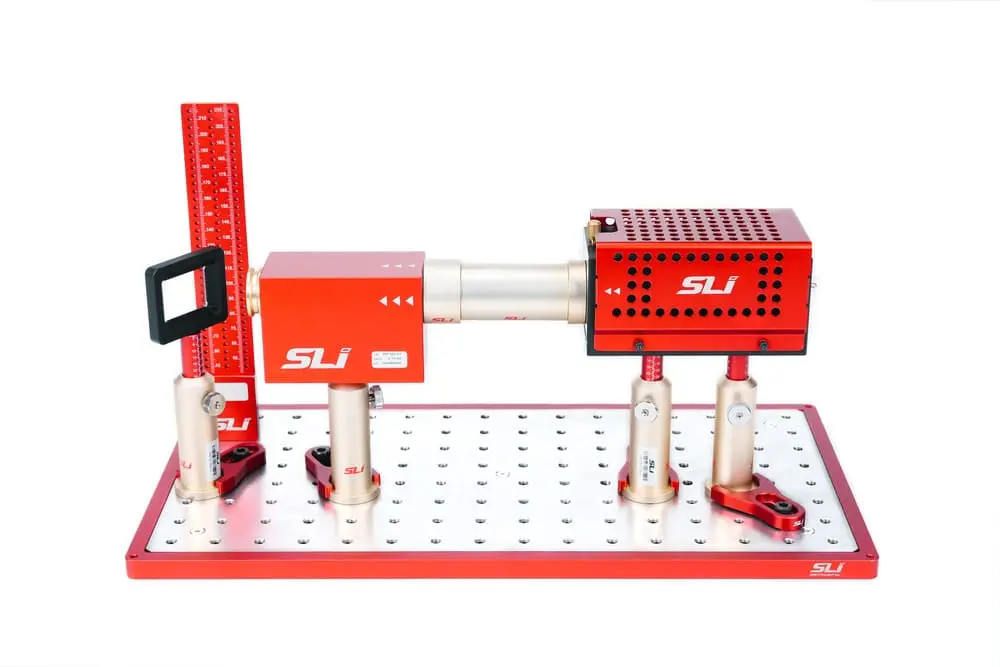

Integration of broadband white light source, automatic wavelength selector and high-resolution spectrometer, realizing stable and clear white light output, intelligent and precise wavelength and bandwidth adjustment of light source output testing

Extremely fast acquisition of spectral data, instantly shorten the detection time, significantly reduce the cost of quality control. High accuracy, fast detection efficiency, so that your project can be more effective with less effort.

Easily adapted to narrow bandpass optical filters, very narrow optical filters, and various types of filters for spectroscopic inspection processes, ensuring worry-free project quality.

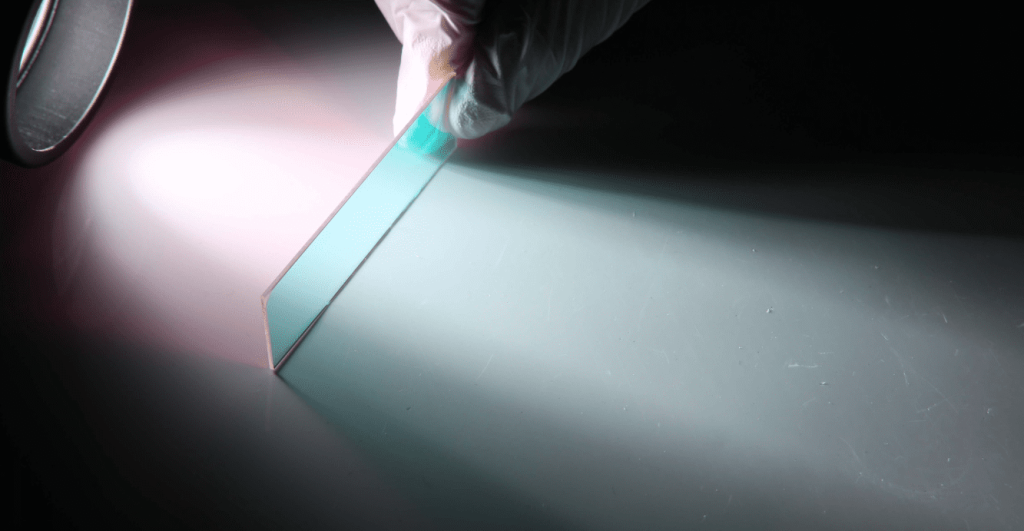

Optical filters are optical components that are active in all major optical devices and can selectively allow a particular band of light to pass through while “masking” other bands of light signals.No. 1. It plays an important role in a variety of optical applications, including microscopic imaging, spectroscopic testing, hyperspectral imaging techniques, industrial inspection, biochemical instruments and scientific research.

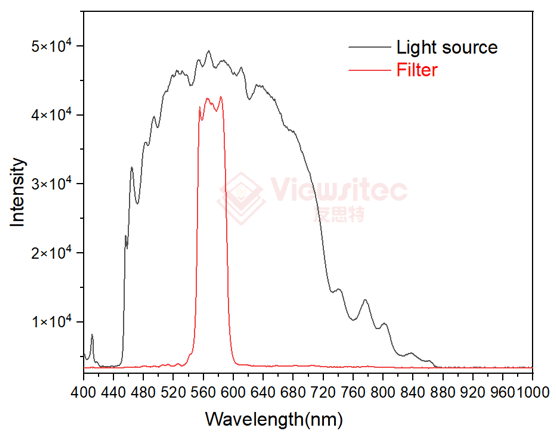

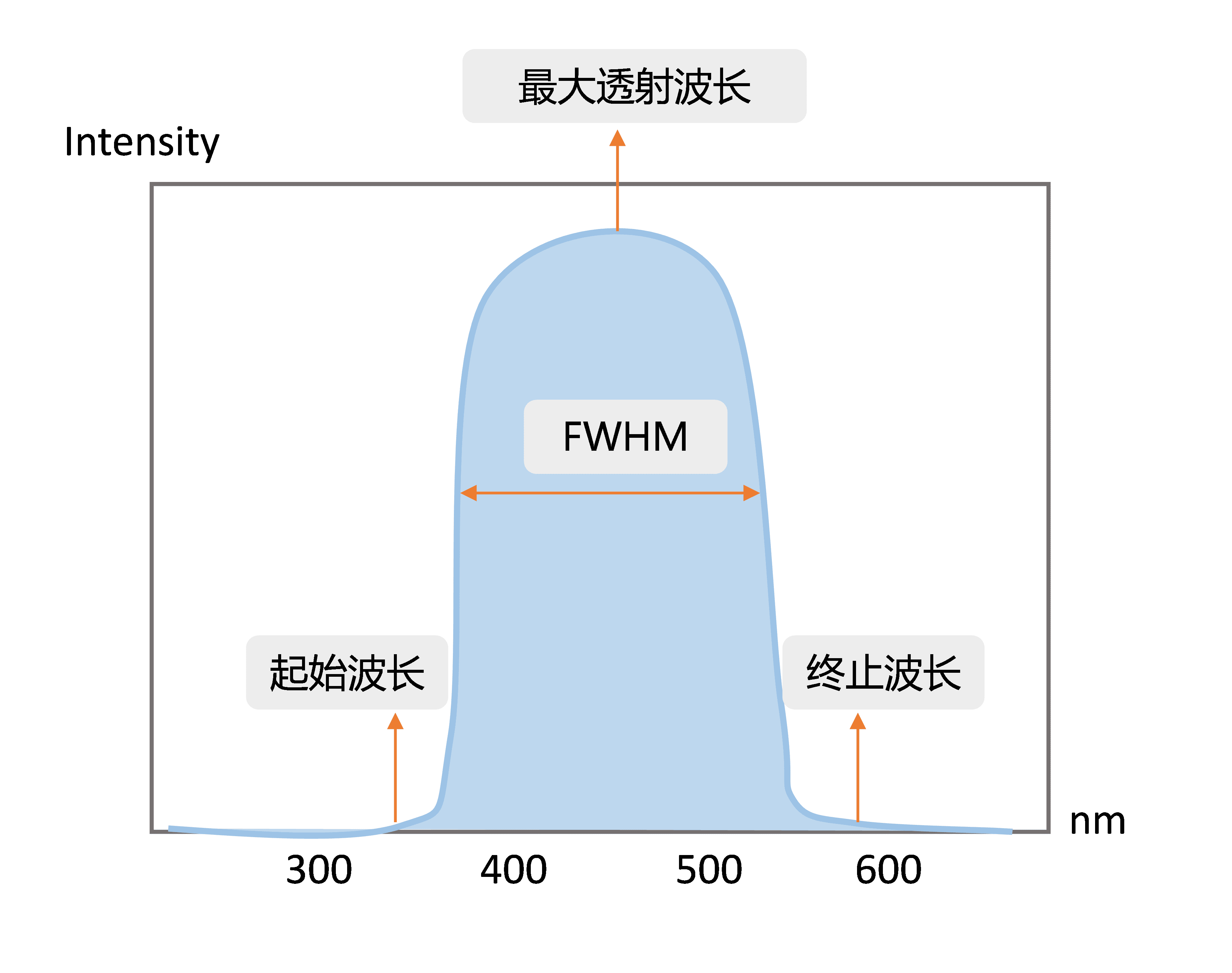

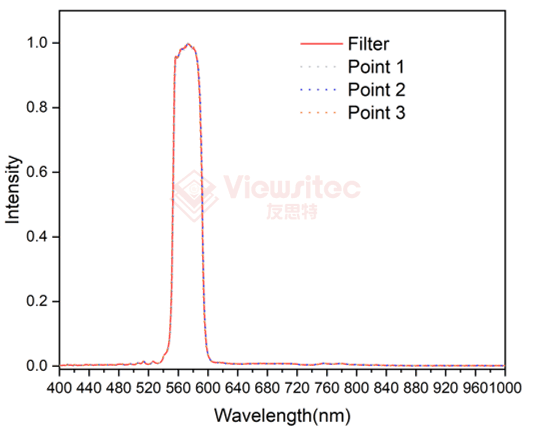

Optical filters have a number of key performance indicators, such as transmittance, cut-off wavelength, polarization, and spectral response curve. By measuring these performance indicators, the response of the filter to the spectrum and its operational performance can be evaluated to ensure its stability and reliability during use.

Conventional optical filter inspection methods usually use a grating monochromator, a spectrometer and a light source system. Before each test, inspectors need to manually adjust the slit of the grating monochromator or calibrate the exit light of the monochromator, and manually record the intensity of different wavelengths passing through the filters on the software, which increases the labor and time cost.

Manual operation inevitably brings about operating errors, thus reducing the accuracy of single-wavelength output detection.

The system integrates a broadband white light source, an automatic wavelength selector and a high-resolution spectrometer to provide stable white light output and automatically adjust the output wavelength and bandwidth of the light source to quickly collect spectral data, significantly shorten the inspection time, and reduce the cost of quality control. At the same time, the system has extremely high accuracy and detection efficiency, and is suitable for spectral inspection of narrow-band and very narrow-band flux optical filters and all kinds of filters.

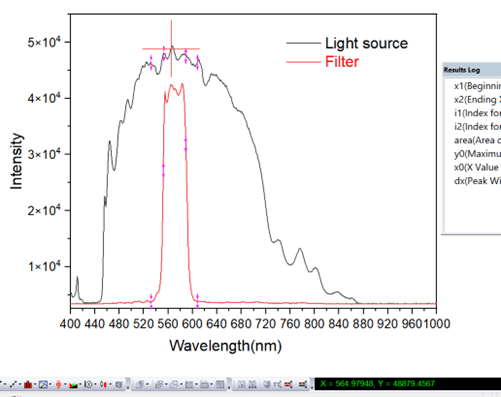

Automatic adjustment of wavelength and bandwidth, detection of the start and stop wavelengths of the filter, the maximum absorption band of the filter, and detection and identification speeds faster than 5ms.

Provides 350-2500nm spectral output, covering most of the working wavelengths of the filter.

Minimum bandwidth can be set to 2nm, resolution <1nm, and minimum 1nm step can be set for precision scanning.

High-resolution spectrometer with low dark noise and stray light to ensure high-speed spectral data acquisition

| 1. Set the parameters and measure the filter spectrum using a broadband light source.

|

| 2. Calculation of pass-through rate

|

|

| 3. Measurement of filter spectra using a single wavelength light source

|

|  |

By combining a customized detection module and a spectrometer, the data can be combined and processed to obtain the transmission spectrum, transmittance, start/end wavelength, and other parameters of the filter. |

Covering the wavelength range of 255-1650nm, the optical precision and quality meets the needs of various applications.

High resolution ensures that you can capture subtle spectral features and precisely analyze subtle changes in each wavelength.

Precise control of wavelength and bandwidth according to project requirements for customized optical performance

Flexible adjustment of the light output slit to meet the needs of different sample sizes and experimental conditions, ensuring accurate data collection.

Powerful white light output ensures sufficient light intensity for a variety of demanding experiments and applications.

Millisecond response time, realizing fast data acquisition and real-time monitoring, improving experimental efficiency and responsiveness.

The Honghong High Spectrum System consists of a high-power infrared light source, tunable wavelength selector, lens and short-wave infrared camera designed for high spectral imaging applications. The infrared light source in the system provides high power output in the 900-1700nm range, while the wavelength selector provides fast, accurate and high-resolution tuning, and the short-wave infrared camera captures the image signals to produce high-quality images as shown in Table 1.

For customers with high spectral imaging needs, we will use the fully automatic tuning wavelength selector FWS-Poly as the core equipment, according to the actual application scenarios, to provide more accurate, high-resolution customized high spectral imaging solutions. This system is suitable for scientific research, industrial inspection and other fields to meet complex imaging needs.

The Mighty Light (MT Light Source) is a multi-functional compact halogen incandescent light source that integrates halogen bulbs, power supply and control board to provide low-noise output.

The MT light source can be directly coupled to a microscope or integrated with a wavelength selector to obtain a tunable monochromatic beam for microscopy, spectroscopy, machine vision and spectral imaging applications.

Honghong's fully automatic wavelength tuning selector consists of a wideband bandpass filter that rotates independently to convert the broadband light source into a combination of light waves of a specified wavelength and bandwidth, and a compensation plate that corrects for spot shifts caused by the two rotating filters.

The technology supports 3-15nm bandwidth and UV to NIR (255-1650nm) wavelength range adjustment, all controlled by software, and realizes high-precision single-wave output.

Our professional Honghong team will be the first to respond and provide you with the best service to solve all your problems.

Address: 3F, No. 99, Jingye 1st Road, Zhongshan District, Taipei City, Taiwan (Da Wan Technology Center Building)

3rd Floor., Dawan Technology Center Building, No. 99 Jingye 1st Road, Zhongshan District, Taipei City, Taiwan

©2025.hongtronics. All Rights Reserved.