[Time Sensitive Networking]

Digital chemical plants require greater interoperability and simplicity of communication, and TSN (Time Sensitive Networking) is a new generation of Ethernet technology specifically designed to meet these requirements. While the introduction of TSN will need to be phased in gradually depending on the industry sector, critical areas such as railroads and aerospace are adopting TSN as the standard IT/OT network for their new platforms.Currently, we provide a variety of TSN solutions such as TSN IP cores, TSN boards, TSN switches, etc., which are embedded in terminal equipment, TSN test equipment and railroad systems in the industrial sector.

Advancing OT/IT Convergence in Industrial Networks

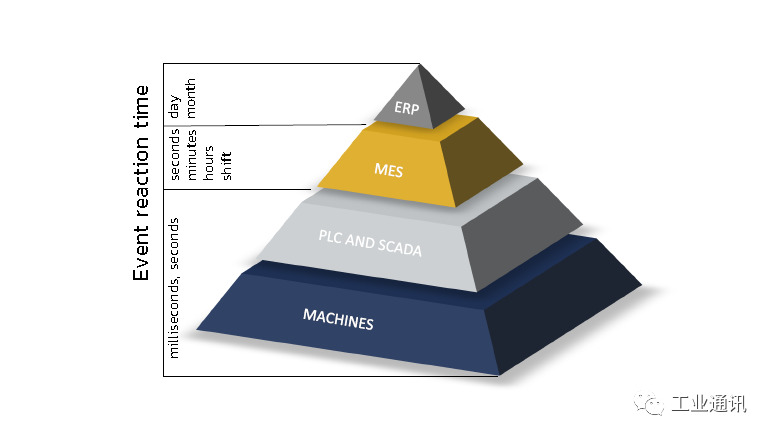

In the stage of Industry 3.0, where industrial automation and digitization are deeply developed, the pyramid-shaped topology of interconnection between production and management is redefined. As shown in Figure 1, at the bottom of the pyramid, production is usually controlled by PLCs with defined input and output logic. Higher up the pyramid, SCADA and industrial MES production management software receives information from the underlying media tools. At the top of the pyramid, ERP-type total resource management software is used to plan the overall business operations of the organization.

The evolution of the digitalization process is based on the extensive use of 'data' and aims to achieve greater productivity through a complete understanding of products and production. This global push to digitize industries is forcing Operational Technologies (OT) and Information Technologies (IT) to interconnect through gateway technologies. The technologies deployed in the OT and IT worlds are often quite different and often not interoperable. This mismatch has led to the emergence of a large number of heterogeneous devices, known as 'Brownfields'.

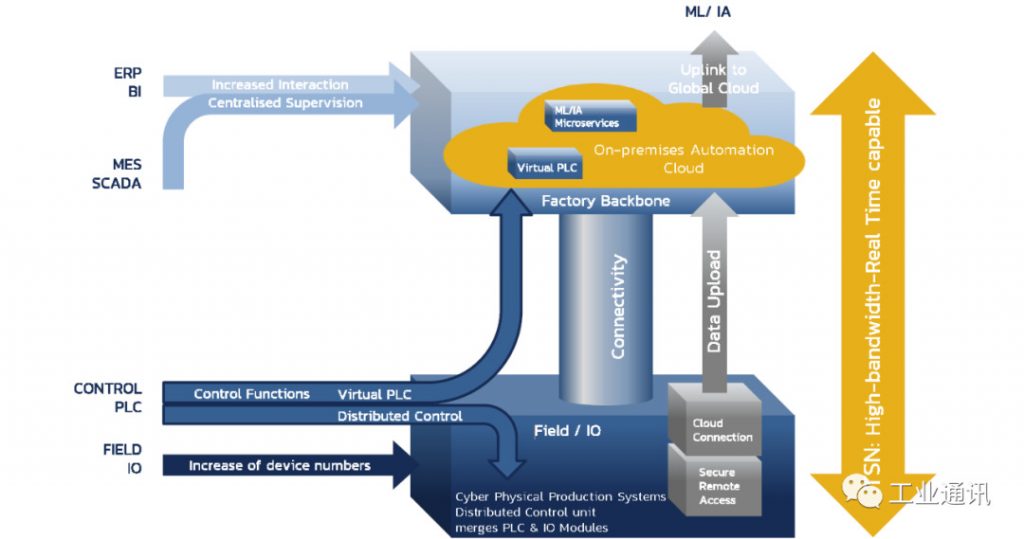

However, the convergence of OT/IT does not stop there; instead, it presents a solution for using communication technologies at the link level that work for both OT/IT worlds. In this way, it is feasible to realize an all-to-all data exchange topology in a homogeneous factory. As shown in Fig. 2, a structure based on distributed control, i.e., input/output units based on a certain level of intelligence and communication capability, is placed at the bottom near the production unit. This structure, called Field I/O, is connected to the powerful computing and communication edge computing devices and local servers to form a Local Cloud.

In this case, traditional layer-based communication and network security schemes are no longer effective. Units included in the field I/O will communicate directly with applications and services, thus requiring a single interconnected network for OT and IT, the so-called Factory Backbone. However, to move from theory to practice, an effective communication technology is needed to support the real-time behavior of OT traffic and the large bandwidth required by IT applications. In addition, it must be secure, even interoperable, standardized and license-free. Time-sensitive network technology is the best solution for this requirement.

Time Sensitive Network TSN

Since 1983, when local computer network solutions were standardized as Ethernet, time-sensitive networking has evolved both technically and application-wise. Although it was originally intended for local computer networks, Ethernet technology has expanded into many other areas. In fact, it has become the de facto standard for field buses and stands out for its wide range of applications in the industrial (Profinet, Ethernet over IP, Ethercat, Sercos III, etc.), electrical (high-availability Ethernet with IEC 61850) and automotive industries.

Various Ethernet-based solutions have emerged in the past to address a key shortcoming of Ethernet in its original version: the lack of real-time communication support. As a result of the adoption of these proprietary solutions, the requirement for certainty in OT has been met. However, the lack of interpretability of solutions from different manufacturers limits the ability of end-users to freely evolve to unique computing and networking infrastructures. Therefore, the market needs standardized technology solutions with guaranteed longevity and vendor independence.Such a solution will significantly reduce equipment costs and maintenance efforts, and greatly simplify the integration of industrial software such as data analysis services, machine learning, MES or ERP.

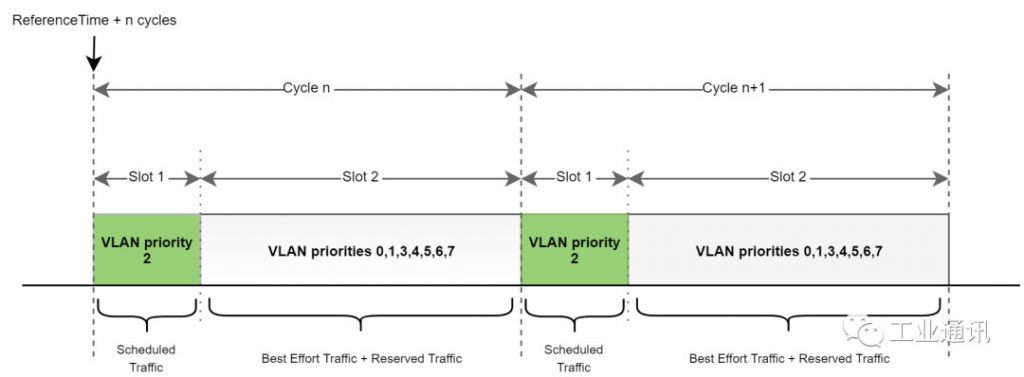

In this sense, the set of IEEE standards defined by the TSN Task Force to provide deterministic communication services over IEEE 802 is known as Time-Sensitive Networking (TSN). The former AVB Working Group, now renamed the IEEE TSN Task Force, is responsible for the development of all standards related to TSN, which is based on the Time-Aware Shaper. This mechanism is designed to divide traffic in an Ethernet network into repeated cycles of fixed duration that are divided into temporary windows based on the TSN configurations allowed by the nodes that comprise the network, and one or more of the eight available Ethernet priorities can be configured and assigned to each time window. The operational details of the time-aware shaper are defined in the IEEE 802.1Qbv standard.

Taking this differentiation capability into account, TSN defines three basic traffic types: scheduled traffic, best-effort traffic, and reserved traffic. Scheduled traffic applies to hard real-time messages, best-effort traffic is regular Ethernet traffic that is not sensitive to any other quality-of-service metrics, and messages that are assigned to different time windows with bandwidth reservations for each priority type are considered reserved traffic. This specific bandwidth reservation capacity is useful for messages with soft real-time requirements, such as video streams.

Figure 3 shows the basic timing diagram of TSN communication. In Fig. 3, each cycle consists of 2 slots. The scheduled traffic is allocated to the first one, while the best-effort traffic and reserved traffic co-exist in the second one. Typical configurations require 8 slots per cycle, which provides enough versatility to define detailed QoS parameters for each data flow.