I. Description of industry pain points

Manuel Hollet, transportation manager at Trench GmbH in Germany, which specializes in precision instrumentation transformers, puts the industry's core pain points into perspective:

"Damage to instrument transformers during transportation is often not immediately apparent. It's important for us to know exactly when the problem occurred."

However, many organizations still rely on traditional mechanical impact indicators. These devices only show that an impact has occurred, but do not record the point in time, number or strength of the impacts, making it impossible for the transportation process to be truly transparent and traceable.

Second, Macrohon ASPION creates "black box" for transportation

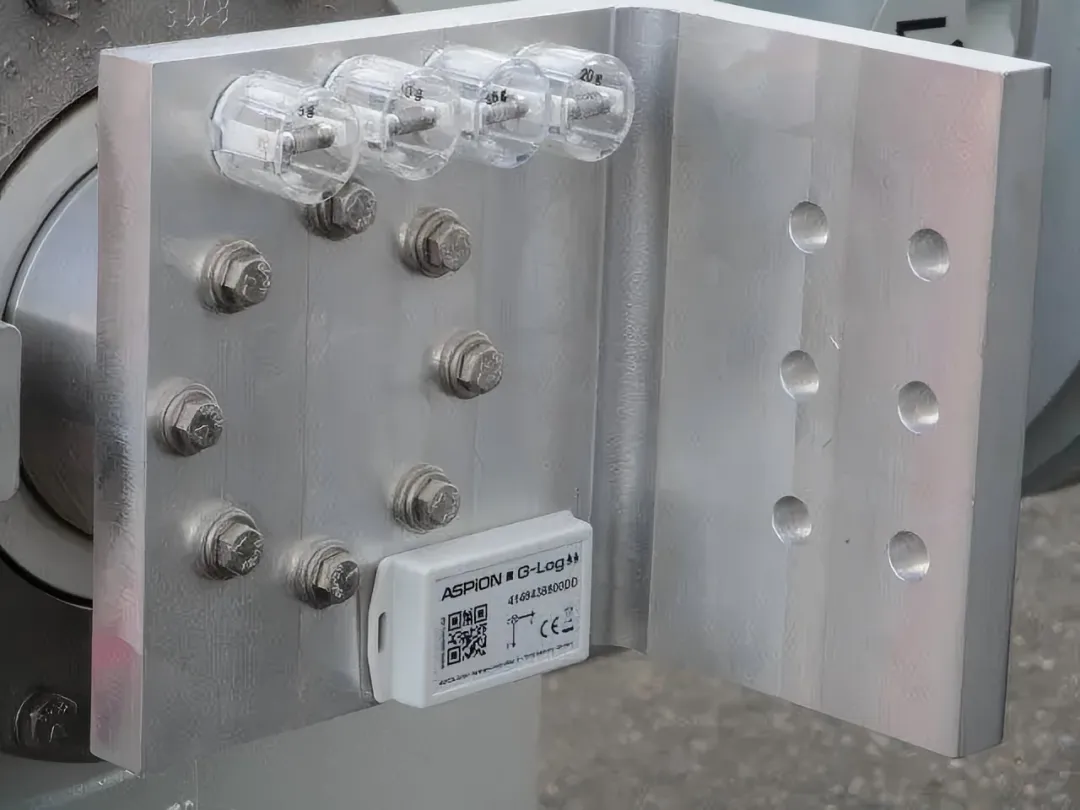

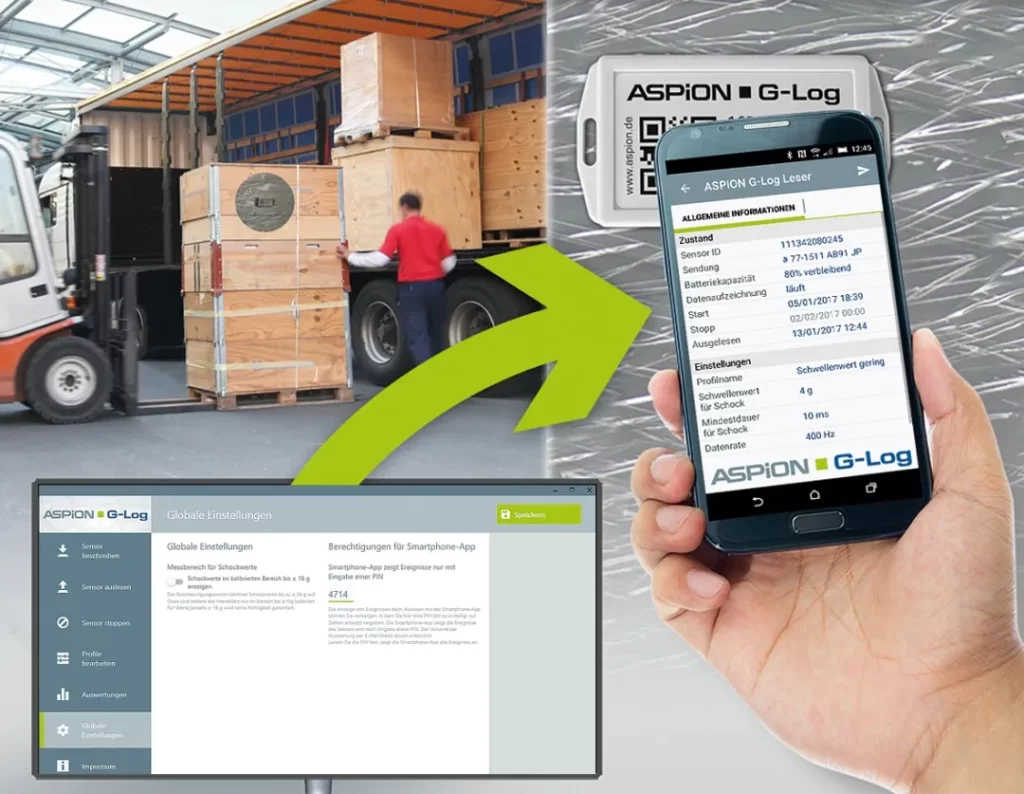

In order to solve the problem of difficult to monitor the transportation process, more and more energy equipment manufacturers are choosing to implement the ASPION G-Log shock recorder. This compact and sturdy device can be installed directly on sensitive parts of the equipment to record vibration, temperature, humidity and other critical data during transportation. The information can be read immediately through cell phone apps or computers, allowing enterprises to keep track of equipment conditions and truly establish a "black box" system for transportation.

The Trench Group in Germany is one of the adopters, with G-Log recorders fixed to its most critical and sensitive components for continuous monitoring, and Manuel Hollet says the solution gives them greater confidence in the quality of their shipments, especially when traveling long distances internationally, where the data clearly helps to trace events and identify responsibility.

⬆ The high voltage instrumentation transformers from Trench GmbH, Germany, can be monitored by the G-Log waterproof recorder even in adverse weather conditions.

Keller HCW GmbH, also located in Germany, shares this concern. The company produces large control system cabinets that are vulnerable to rough handling during transportation. Ulrich Wiewel, who is in charge of quality inspection at Keller HCW GmbH, says that the company's large control system cabinets are susceptible to rough handling during transportation:

"MAXTRON ASPION's solution is easy to operate, flexible in settings, and capable of monitoring both temperature and humidity at the same time. Our staff can read the data from the mobile app and upload it to the server as soon as the control cabinet arrives at the customer's site. It's highly efficient and makes quality traceability more reliable."

⬆ Easily and reliably monitor shock-sensitive control cabinets such as the Keller HCW with the G-Log Shock Recorder.

C. Early detection of transportation damages saves more than just costs

Recognizing potential damage to equipment before it is put into service is a critical aspect of quality management. The data recorded by ASPION G-Log can accurately show the time point of critical events, which not only helps companies to quickly identify the source of the problem, but also plays an important role in insurance claims and liability determination.

Trench's Manuel Hollet said:

"As we deliver on international trade terms, these timing details are very important to us and they directly determine whether or not the insurance is in force at the time of the incident."

In the photovoltaic industry, hidden damage caused by transportation is also a major risk. When pv-sos GmbH imports photovoltaic modules from China, it pays particular attention to the problem of hairline cracks that can be caused by transportation. Such damage is difficult to detect initially and often results in failures only after several years of use.

Alexander Marxreiter, General Manager of the company, shared:

"The highly accurate data provided by ASPION G-Log enables us to detect any abnormalities in the transportation process earlier. More importantly, these complete and detailed records greatly enhance our persuasive power when communicating and negotiating with insurance companies."

Quality Assurance in Global Transportation

In a globalized supply chain environment, the transportation risks faced by equipment manufacturers are more complex and volatile than ever before.

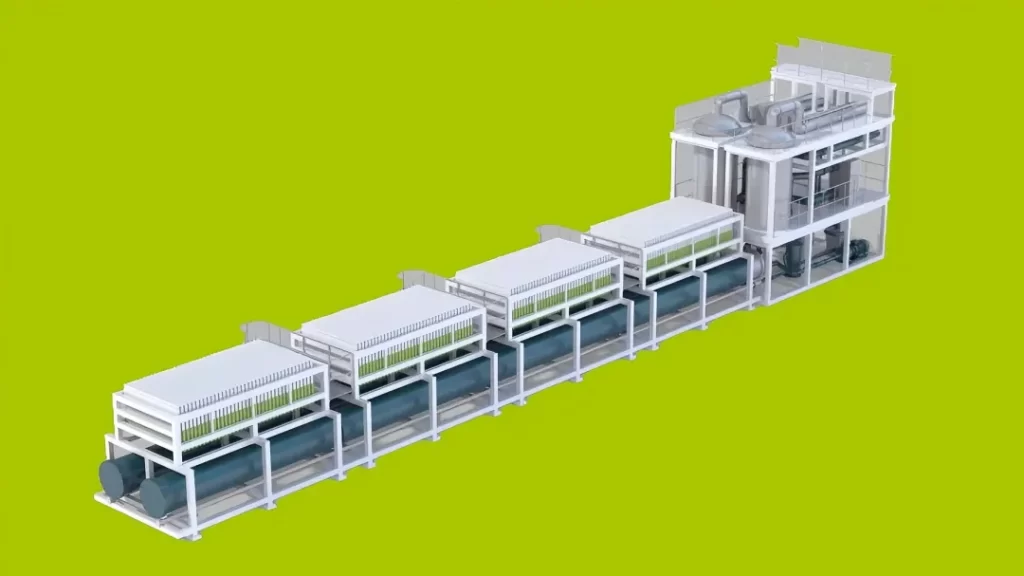

thyssenkrupp nucera, the world's leading manufacturer of green hydrogen systems, has implemented the Acer ASPION Shock Recorder solution as a key management tool for quality assurance in its international transportation processes.

Stefan Heimann, Technical Procurement and Manufacturing Module Engineer, shares their experience with the program:

"We have the flexibility to activate the loggers from anywhere in the world via QR Code and an app, which is simple and intuitive to use and requires little additional training. What's more, all the recorded data is automatically synchronized to the cloud, so our suppliers and teams can keep track of the status of their shipments in real time. If something goes wrong, we can take immediate action."

This digital monitoring makes thyssenkrupp nucera's supply chain management more efficient and controllable, and effectively ensures the quality and reliability of every critical component in transnational transportation.

V. Compliance with international standards, enhanced traceability and compliant transportation

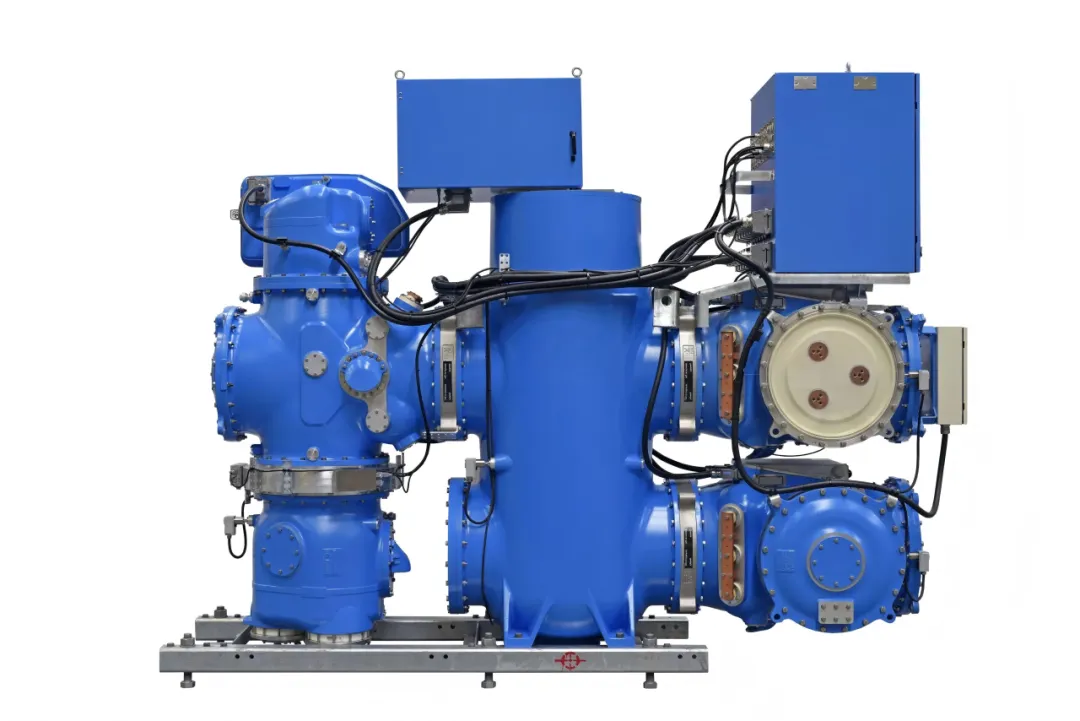

For companies that need to comply with international transportation regulations, the ASPION G-Log 2 offers seamless compliance. By supporting the common transportation classifications (2M4 / 2M5 / 2M6) in the EN IEC 60721-3-2 standard, companies can implement standardized transportation monitoring and facilitate subsequent compliance verification.

Siemens Energy Global in Berlin, for example, uses this solution to monitor the vibrations of large circuit breakers during their global transportation. When the actual vibration exceeds a predefined threshold, the system automatically flags the data in red, allowing the engineering team to quickly review and make a judgment after the event.

Heike Steigert, Mechanical and Prototype Test Engineer at Siemens Energy, shared:

"The ASPION system allows us to quickly verify that the transportation process is in compliance with standards. This intuitive way of presenting data has greatly improved the efficiency of quality management."

Conclusion: Starting from the first transportation, security and transparency are synchronized.

Manuel Hollet, Transportation Manager at Trench GmbH in Germany, also drew clear conclusions about this option:

"Hong Kong's ASPION DataCORDER has delivered tangible benefits from the very first introduction. It continuously records critical events in the transportation process, allowing us and our customers to take early action to avoid potential risks."

The real value of so-called "visual transportation" lies in the fact that companies can no longer only deal with problems after the fact, but can use real-time and credible data to build greater customer trust and optimize the overall supply chain process in a more scientific way.

Digital transportation monitoring is fast becoming the new standard for quality assurance and accountability, regardless of whether a company is in the field of energy equipment manufacturing, system integration, or electrical engineering projects. The ASPION G-Log provides a simple, reliable, and verifiable solution that allows every piece of equipment to be fully documented and quickly verified.

Want to make equipment transportation more transparent and traceable?

Want to make equipment transportation more transparent and traceable?Honghong ASPION G-Log Shock RecorderIt helps companies to keep abreast of shocks, impacts and environmental changes, reducing transportation risk and increasing customer trust!right nowMake an appointment for personalized consultationContact us to learn how you can enhance your supply chain quality and risk management through Visual Transportation!

Honghong will provide you with any support you need!

Our professional Honghong team will be the first to respond and provide you with the best service to solve all your problems.