Honghong will provide you with any support you need!

Our professional Honghong team will be the first to respond and provide you with the best service to solve all your problems.

Vibration shock monitoring equipment to solve transformer transportation safety hazards

Small vibrations or impacts in the transportation of large power transformer equipment may cause hidden dangers for subsequent use. These damages occurring in the transportation process will not be immediately apparent, but if the problem is discovered after it is put into use, it will seriously affect the progress of the project and increase the cost of the project and the cost of accountability. Honghong provides you with a variety of transportation monitoring solutions. Through vibration and impact monitoring, we can accurately monitor the transportation of transformers throughout the entire process, detect and solve potential problems as early as possible, ensure the safe transportation and normal operation of transformers, help you determine the performance and status of equipment after transportation, and improve the efficiency of acceptance.

International standards have specific requirements for the transportation of transformers and transformers. For example, China's GBJ148-90 "Electrical Installation Engineering Power Transformer, Oil-immersed Resistor, Transformer Construction and Acceptance Standard", Article 2.1.3 points out that transformers, reactors in the process of loading and unloading and transportation, there should not be a serious impact and vibration. Transformers with voltages of 220KV and above and capacities of 150,000KVA and above and reactors with voltages of 330KV and above should be equipped with shock recorders. Article 1.0.4 also points out that transformers and reactors should be inspected and recorded in time when the mode of transportation is changed during the transportation process.

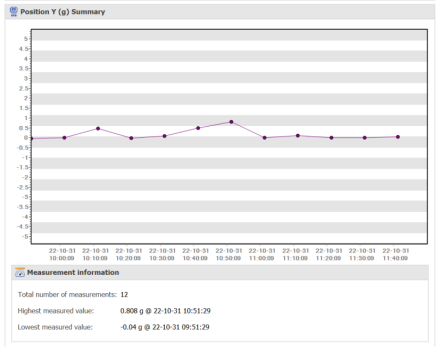

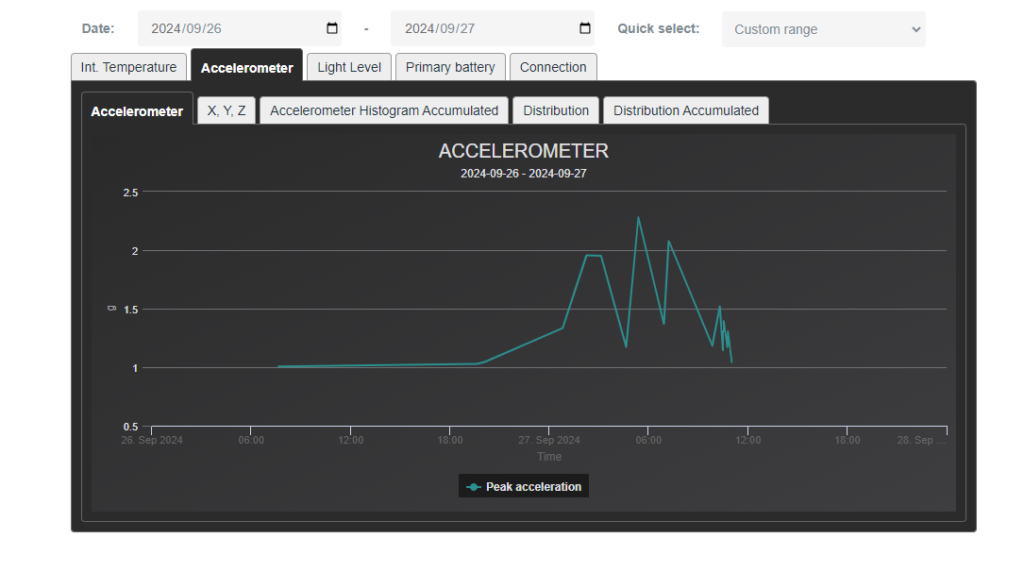

Accurate, wireless, compact, and with long standby time, the MSR165 is one of the best-selling vibration and shock data loggers on the market! High-performance 3-axis accelerometers are integrated into a miniature device that accurately records vibration changes at all time points during transportation for liability identification and transportation plan optimization.

With a sampling rate of up to 1600/s and a maximum accuracy of ±0.15g, the HH-MSR165 ensures accurate vibration shock measurements during transportation.

Two monitoring modes, vibration or shock, can be set. Records all vibration and shock events exceeding the set threshold during transportation of precision machinery.

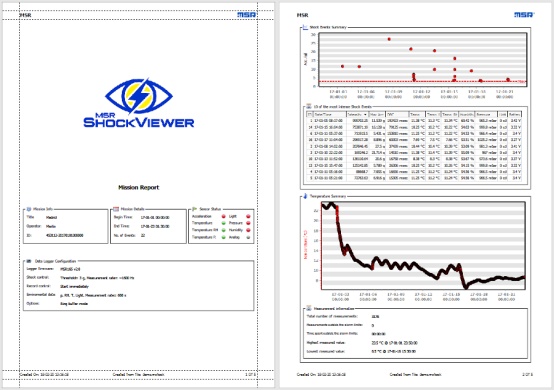

Equipped with MSR PC software for professional data analysis, it can analyze the impact events in detail and generate professional impact report descriptions.

Temperature, humidity, air pressure or light sensor can be added according to customer's requirement for more flexibility and wider application range.

① MSR165 Host

② Tri-axial acceleration sensor ±15g

③ Rechargeable Battery 900 mAh

④ Memory capacity 2 million measurements

① MSR165 Host

② Tri-axial acceleration sensor ±15g

③ Optional 7700mAh battery

④ SD card (memory capacity 1 billion measurements)

The HH-MSR165 can be used in a wide range of applications in the transportation and packaging industry, automation industry, railroad, science and technology, industrial manufacturing, automation and machine building.

MSR Enables Safe Transportation of Fragile Artwork - Develops New Processes to Effectively Reduce Shock and Vibration

An in-depth look at the application benefits, working principles and real-life examples of the MSR Transportation Vibration Recorder: A guide to logistics security and cargo protection.

How Uroviva Uses MSR Data Recorders to Monitor Transportation Shocks and Vibrations in Highly Sensitive Medical Devices

Protecting the nation's sacred mountain-The wafer transportation recorder used by TSMC-MSR 175 Plus!

Whether it's for acceptance accountability, early detection of damage or packaging optimization, the MSR175 Shock Recorder accurately records critical transportation events such as shock, jolt, temperature, pressure or humidity fluctuations, providing objective measurement data.

Two digital 3-axis accelerometers (±15g and ±200g) are integrated in the HH-MSR175 device to record shocks at a measurement frequency of up to 6400/s. The HH-MSR175 device is designed to be used as an accelerometer, and is capable of recording shocks at a frequency of up to 6400/s.

The EDR memory can store more than 2 million measurements, enough to withstand more than 1,000 shocks.

GPS/GNSS (Global Navigation Satellite System) receivers that seamlessly capture potentially destructive impact events and record the geographic location of the event.

The HH-MSR175 software allows easy configuration of the shock recorder, MSR ReportGenerator automatically generates reports, and MSR ShockViewer analyzes shock events in detail.

① MSR175 Host

② Tri-axial acceleration sensor ±15g

③ Tri-axial acceleration sensor ±200g

④ Temperature sensor

⑤ Rechargeable Battery 230 mAh

① MSR175 Host

② Tri-axial acceleration sensor ±15g

③ Tri-axial acceleration sensor ±200g

④ Temperature sensor

⑤ Replaceable Battery 7700 mAh

① MSR175 Host

② Tri-axial acceleration sensor ±15g

③ Tri-axial acceleration sensor ±200g

④ Temperature sensor

⑤ Humidity Sensor

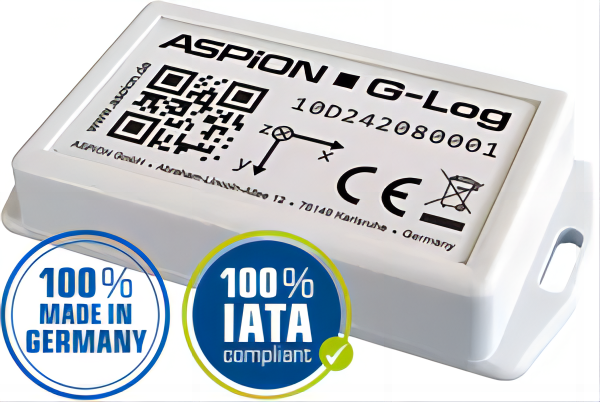

The rugged, durable and cost-effective shock recorder ASPION G-Log provides a complete record of vibration, shock and temperature data during the transportation of goods and commodities.

The ASPION G-Log series of shock recorders are compliant with the European Transportation Standard IEC 60721-3-2 and have been developed specifically for transportation monitoring of sensitive goods and commodities.

With 3-axis acceleration, it can record vibration up to ±24g, as well as temperature and humidity data.

Easy to operate, one-click configuration, data can be read quickly via PC, NFC or Bluetooth, and automatically supports multi-language switching.

① ±24g shock acceleration sensor

② Temperature Sensor

③ 286 impact events

④ Wireless data transmission using NFC

⑤ Optional IP67 protection level.

① ±24g shock acceleration sensor

② Temperature Sensor, Humidity Sensor

③ 950 impact events

④ Wireless data transmission with NFC/Bluetooth

⑤ Optional IP67 protection level.

⑥ Batteries can be replaced

ASPION Vibration Shock Recorder: Customized Monitoring Solution for Your Cargo Transportation

ASPION G-Log is the strongest gatekeeper who can control the impact details of transportation - the safety of wind turbine blades is guarded by ASPION G-Log!

The Trusted Vibration Impact Location Recorder monitors vibration, impact, temperature and humidity, light, pressure, and tilt. It is tracked by GPS, GSM, radio signal and Iridium™ satellite technology to protect the safety of your shipments.

Utilizing GPS, GSM, radio signal and Iridium™ satellite technology, it enables local and global asset tracking and provides accurate map viewing.

Advanced data logging and low-power operation modes ensure long battery life when the device is not in operation, extending the tracking device's continuous operating time.

Ruggedized design for a variety of environmental and weather conditions, non-destructive and easy to install, and capable of consistently collecting and delivering real-time data from assets.

Trusted can be used in a wide range of applications such as construction, rail, leasing, wind energy, transportation and security.

①Small frame design, suitable for applications with limited space.

② Supports 4000 transmissions with moderate battery life for regular use.

③ Flight Approval: Applicable to air logistics tracking.

④ Wireless, IP69K rated to protect the device from water and dust.

⑤ Supports monitoring functions such as vibration, tilt, and illumination.

① Small frame design, slightly increased thickness to extend battery life.

② Support 2900 transmissions, slightly shorter than T7.

③ Support LTE/2G network to provide global coverage.

④ Extra battery life: Improved battery life in a small size.

⑤ IP69K protection rating, suitable for use in harsh environments.

① Larger frame design for situations that require more functionality and longer battery life.

② Support 7000 transmissions, suitable for long time and long distance tracking.

③ Support LTE/2G network with global coverage.

④ IP69K level protection ensures the stability of the equipment in harsh environments.

The Tive Solo 5G logger tracks and transmits the location, temperature, humidity, and impact strength of the leaves during transportation and updates the transportation status to the Tive cloud platform via cellular network or WIFI in real time.

Using the latest global cellular, WiFi and GPS technologies, it realizes real-time positioning and monitoring of logistics, accurately capturing and transmitting the location of goods to prevent delays and damages.

Supporting temperature, humidity, light, vibration and shock sensing functions, it is able to monitor and capture environmental changes in the logistics process in real time to ensure the quality of goods.

Depending on the model, different battery life options are available, which can last for 30 to 60 days to meet the needs of long-distance transportation.

Tive 5G can be used as a disposable tracker and is ideally suited for last-mile deliveries.

①Rechargeable nickel batteries with a battery life of over 100 days.

② Built-in sensors for temperature, humidity, light, and vibration.

③Supports network connection from 2G to 5G with 2G fallback function.

④ Support road, air, sea and rail transportation without UN3481 air transport label.

⑤ Highly durable plastic casing with IP67 protection rating

①Rechargeable lithium-ion battery provides more than 100 days of runtime

② Built-in sensors for temperature, humidity, light, vibration and motion.

③ Supports 2G fallback using 5G, WiFi and GPS technology

④ Supporting multiple modes of transportation, including road, air, sea and rail transportation

⑤ IP67 protection, water and dust resistant.

Our professional Honghong team will be the first to respond and provide you with the best service to solve all your problems.

Address: 3F, No. 99, Jingye 1st Road, Zhongshan District, Taipei City, Taiwan (Da Wan Technology Center Building)

3rd Floor., Dawan Technology Center Building, No. 99 Jingye 1st Road, Zhongshan District, Taipei City, Taiwan

©2025.hongtronics. All Rights Reserved.