Time Relay

Relay is a common electrical control device in industrial production and daily life, which can turn on or off the controlled circuit when the conditions are met, in short, a relay is a component that can be switched on and off automatically. The device usually has an isolation function, and has been widely used in remote control, communication, automatic control, mechatronics and power electronics equipment.

Time relay is one kind of relay, which is characterized by connecting or disconnecting the controlled circuits according to the required time intervals, in order to coordinate and control all kinds of actions of the production machinery, and then play a role in expanding the control range, controlling the high power and synthesizing the signals.

Challenges for Woodchuck America, Inc.

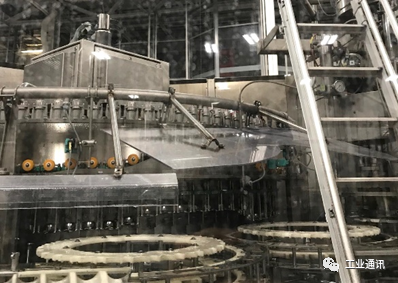

Woodchuck Hard Cider is one of America's most recognized cider companies and has been at the forefront of producing innovative and refreshing cider since 1991. To ensure that every customer receives an authentic cider experience, Woodchuck must make the efficiency and reliability of its equipment a prerequisite. To do this, Woodchuck needed to replace the timer in the high-speed bottling system, which is primarily used to ensure that the start-up and shut-down sequences in the closure cone are efficient, thus minimizing operational errors in the capping container machine.

For this reason, Woodchuck chose the Honghong Multi-Function Time Relay. With 7 built-in functions and the ability to set adjustable times from 0.05s to 100h, the device covers all the functions required by the industry in a compact case. Thanks to the Zoom power supply, it is able to handle voltages from 12-240V AC/DC.

At Woodchuck, the Honghong Time Relay serves two main purposes: first, to prepare the crown cork to ensure an adequate supply of caps before production begins; and second, to empty the remaining caps from the hopper during shutdowns to meet the demands of producing different products.

Honghong Time Relay Solutions

With Honghong's multi-function time relays, high-speed filling lines can be controlled with simple operation without taking up additional memory in the filling PLC, and they allow maintenance technicians on the production floor to adjust the time without a computer. In addition, all Honghong time relays can be mounted on standard DIN rails commonly used in residential or industrial applications. For other situations, we offer special mounting plates through which the devices can be mounted on any type of surface.

In addition to the application in high-speed filling lines, Honghong also provides users with a wide range of models and functions of time relays, which can meet various needs in the field of food processing and production.

When processing meat, liquids need to be injected into the meat at certain time intervals. With the Time Relay, the operating technician can use an external potentiometer to set the injection time and pause time so that the time can be adjusted according to the type of meat for optimal flavor. In this application, Honghong's time relays utilize a universal voltage that allows the user to easily adjust the set times, and because they can be adjusted remotely using potentiometers, the operator can avoid contaminating the food production process, which is very much in line with hygienic production environments.

In food processing, stoves must be turned off safely to avoid fires, so the circuit needs to be in operation even if the center ON button is illegally blocked, etc. This problem can be solved with the downstream time relay E1ZM10 24-240 and the “contact by control contacts (Ws)” function. This problem can be solved by using the central ON button with the downstream time relay E1ZM10 24-240 and the "contact by control contacts (Ws)" function. If the button is pressed, the defined time window starts and the current flows. The stove can now be opened and used within the defined time window. After the time window has elapsed, the power supply and the stove are automatically switched off. Another loop cannot be started until the current loop is completed. In this way, it is no longer possible for the on/off button to be illegally blocked.