Honghong will provide you with any support you need!

Our professional Honghong team will be the first to respond and provide you with the best service to solve all your problems.

- Extremely low stray light: The gratings are holographically recorded using two highly collimated, clean and uniform beams, resulting in straight and equally spaced grooves. The diffracted light from these gratings has no ghosting spectrum. The randomly scattered light is as low as that from a good front surface aluminum reflector.

- High efficiency: The notch profile is symmetrical sinusoidal and the notch depth is optimized for the spectral region used. For maximum efficiency, these gratings are preferred in configurations where only two diffraction levels (-1 and 0) are present, i.e., high notch frequencies are preferred. The combination of flat grating surfaces, very straight and equally spaced notches provides a flat diffracted wavefront for maximum wavelength resolution.

- Accurate Notch Frequency: The notch frequency of the grating is accurate to within ±0.2 notches/mm of the nominal value. This means reliable wavelength readings in your instrument.

- Laser tuning gratings are holographic gratings specifically designed for laser wavelength tuning, such as dye lasers, titanium sapphire or external cavity diode lasers. The notch depth is optimized to produce a polarized state with maximum efficiency.

- Very low stray light: Holographic masters for dye laser gratings are manufactured using the same technology as our low stray light gratings. This produces a very small amount of scattered light, comparable to a good front surface aluminum reflector.

- Littrow gratings: Littrow mounts or autocollimators are the classic configuration for laser tuning. In order to fill the aperture of the grating and achieve high resolution, the laser beam has to be expanded through the cavity optics.The Littrow configuration is also frequently used for external cavity tuning of diode lasers. Especially in the near infrared, very high efficiencies (>90%) can be realized.

- A device commonly used for laser pulse compression, which converts and compresses pulses by utilizing the diffraction principle of a grating.

- With excellent grating diffraction efficiency and high laser damage threshold, it is very suitable for chirped pulse amplification (CPA) technology for picosecond and femtosecond ultra-short pulse lasers.

- Material: Gold plated (Au) standard with λ > 750 nm. Standard substrate material: Optical crown glass K4A or N-ZK7 Optional substrate material: “Zero” thermal expansion glass-ceramics

- Extremely Low Noise: Rowland holographic gratings are manufactured using the same proprietary technology as our low noise flat gratings.

- Good resolution: The aberration of all points on the Roland circle (except astigmatism) is very small, which allows the grating to be used over a wide spectral range. Since all diffraction steps are concentrated on the Roland circle, different steps can be measured at the same time.

- It can be used in the fields of spectroscopy, spectral analysis, lasers, etc. It can also be used to make high-precision optical components such as optical instruments, optical sensors and optical communication devices.

Outstanding, no fear of comparison! Six core advantages, leading the photoelectricity testing first!

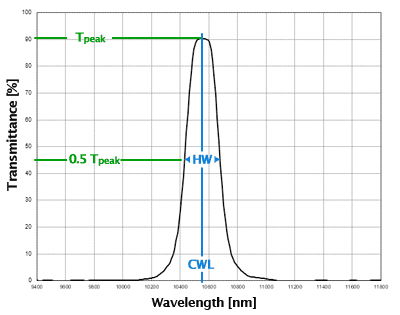

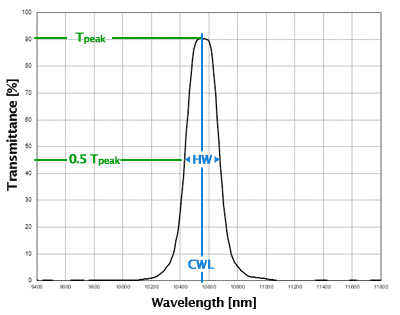

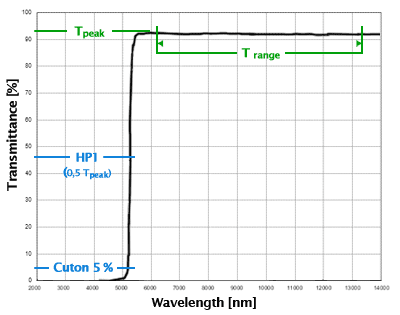

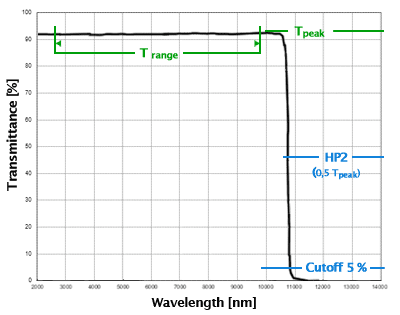

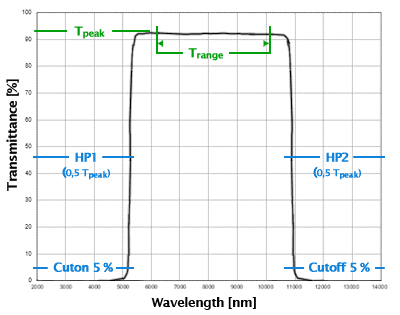

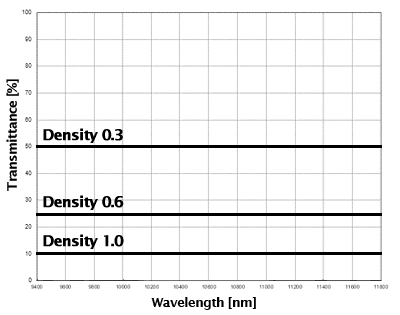

Filters with high transmittance, high suppression outside the passband, good surface quality and coating uniformity.

Holographic gratings with high efficiency, wide tuning range, high damage threshold and optimized range for specific applications

Filter range of 400-14000nm, holographic grating range of 200-2000nm, to meet the needs of various projects

Multi-series and multi-models are available to meet the needs of various projects with a wide range of applications.

These optical components are manufactured using advanced manufacturing techniques to ensure highly accurate optical performance and long-term stability.

Designed to meet industry standards for durability and stability in a variety of environments and applications.

More one-stop solution products to provide all-round project protection

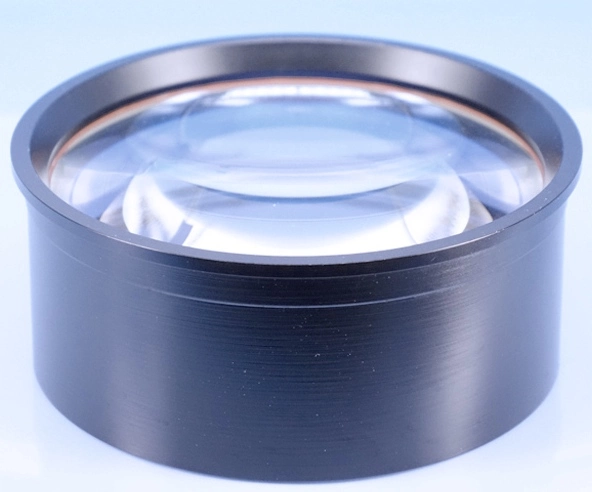

Manufacture and supply of optical filters for filters or supply of fully assembled filters.

optical filter

We manufacture filters and windows from Ø5.0 to Ø200.0 mm. Wafers can be cut to custom sizes as small as 1.0 x 1.0 mm. Thicknesses range from 0.3 to 3.0 mm. High transmittance, high out-of-band rejection, good surface quality and coating uniformity give our filters excellent performance.

We help customers design and manufacture optical filters, purchase filter wheel parts, and assemble complete filters.

Benefits of buying a complete filter wheel kit:

Our professional Honghong team will be the first to respond and provide you with the best service to solve all your problems.

Address: 3F, No. 99, Jingye 1st Road, Zhongshan District, Taipei City, Taiwan (Da Wan Technology Center Building)

3rd Floor., Dawan Technology Center Building, No. 99 Jingye 1st Road, Zhongshan District, Taipei City, Taiwan

©2025.hongtronics. All Rights Reserved.