Honghong will provide you with any support you need!

Our professional Honghong team will be the first to respond and provide you with the best service to solve all your problems.

Solectrix In-Vehicle Image Capture Card and Playback System

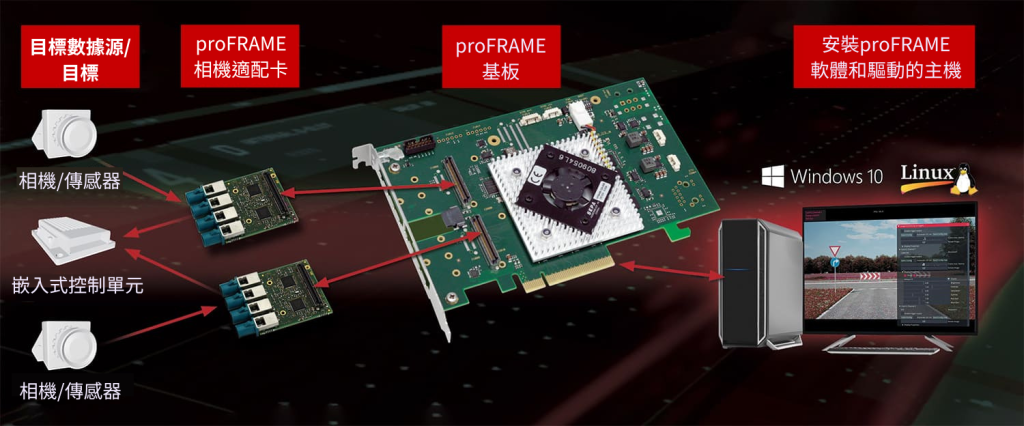

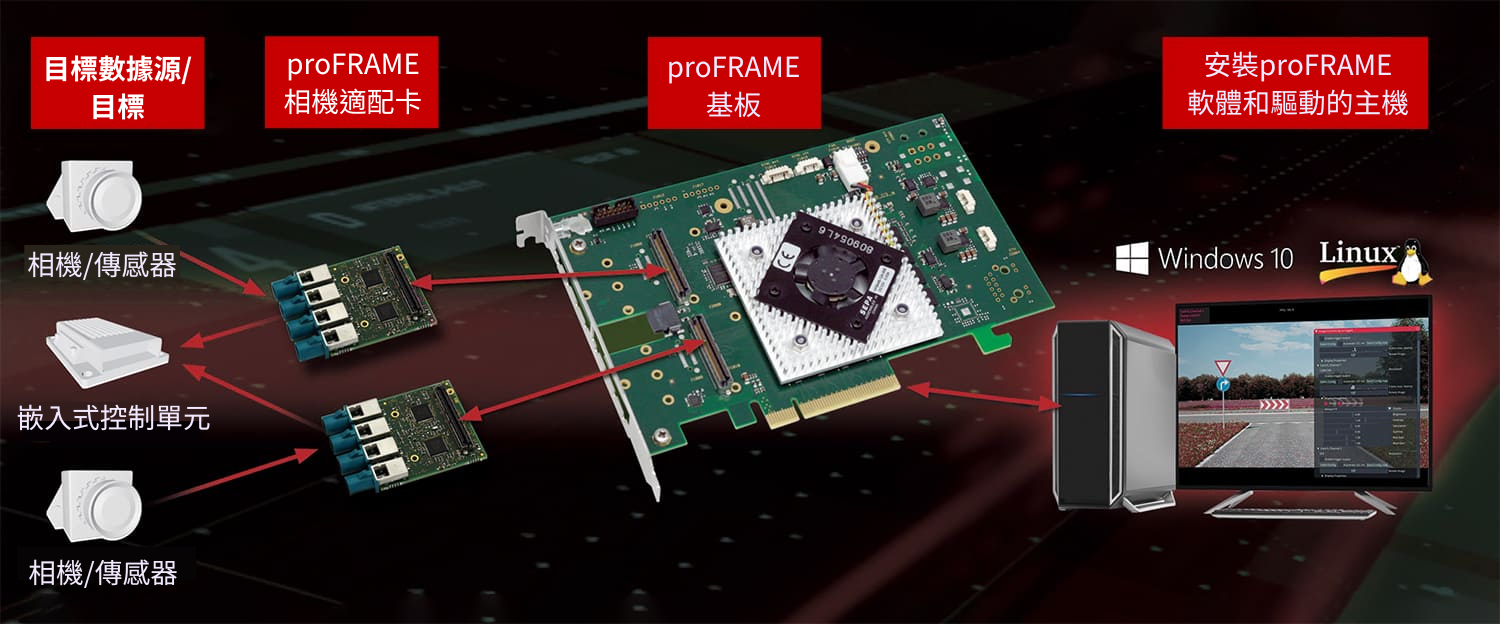

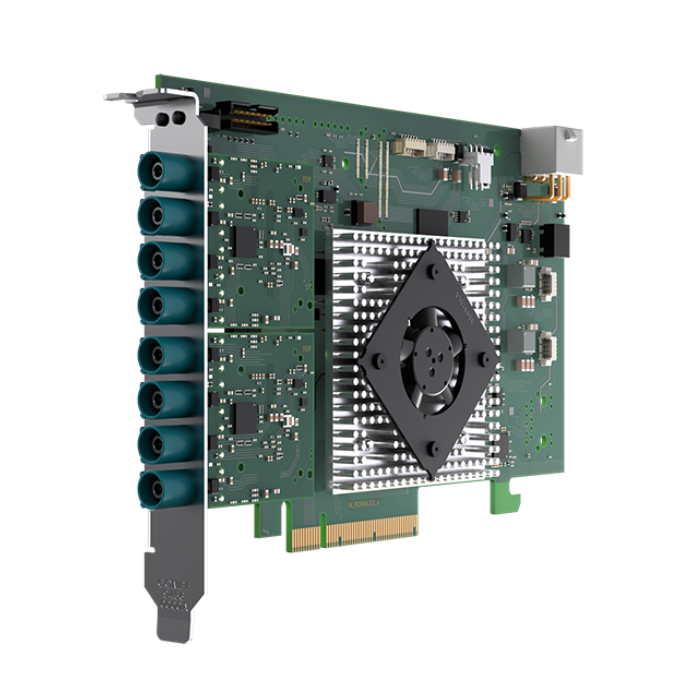

proFRAME Series Modular solutions for video and data acquisition and playback.

Higher data rates and longer transmission distances for capturing, playing back and processing a wide range of raw movie data streams.

Highly accurate real-time data acquisition + record replay for up to 8 data streams, 1 system with flexible switching between 2 modes of operation (acquisition/playback), support synchronized acquisition input/output processing

Supports multiple interfaces and various common transmission technologies such as GMSL2™ and GMSL3™, FPD-Link™ III and IV, GVIF, etc. (other technologies available upon request)

For the development and validation of ADAS, as well as industrialized applications in medical technology, digital microscopy and EOL testing.

proFRAME is a modular video capture card system designed for capturing and playing back video data streams. The system is widely used in many applications, including:

It also provides efficient and accurate image processing solutions to meet the diverse needs of various industries.

quintessentially proFRAME Use case overview:

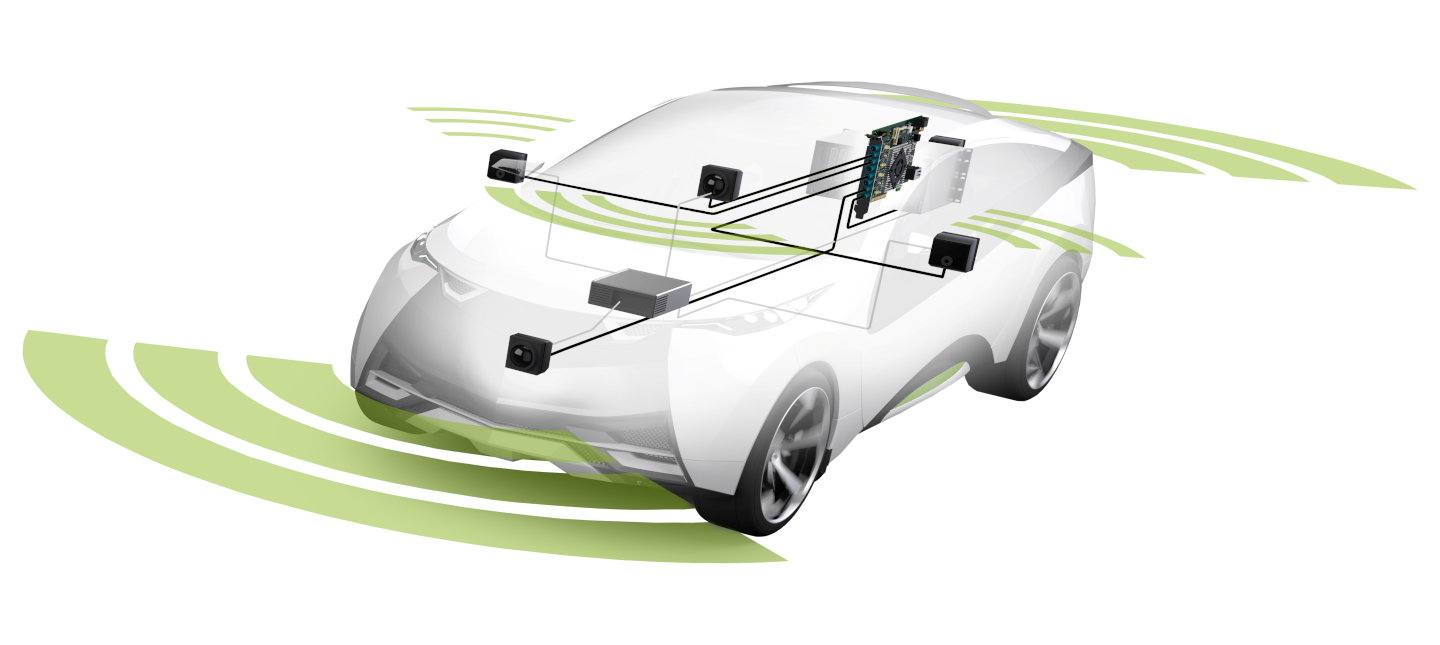

Test Drive Data Record: During the test drive, video data from a number of on-board cameras is captured synchronously. This data provides key support for driver assistance functions such as traffic sign recognition, lane departure warning and park assist, as well as for the operation of the automated driving system (ADAS/AD).

Driving Scene Reproduction and Verification: The driving scenes are recorded as part of the test drive (data logging) and synchronized with the video streams from the respective cameras with high precision time stamping. These scenes are then used for hardware-in-the-loop (HiL) testing to verify system functionality with real sensor data.

Modular Video Capture and Playback System: Solectrix proFRAME The series supports mainstream GMSL™ and FPD-Link™ in-vehicle cameras, which have been widely used in data loggers for many years, demonstrating stable and reliable performance.

proFRAME 3.0 Features and Benefits:

proFRAME 3.0 is a powerful modular solution that provides a high degree of flexibility and accuracy in vehicle data recording and testing for a wide range of driver assistance and autonomous driving applications.

In the Hardware-in-the-Loop (HiL) test for Advanced Driver Assistance Systems (ADAS) and Autonomous Driving (AD), driving scenes are imported into the ADAS/AD control unit (ECU) in the form of video streams and precisely played back in time-stamped recordings made during a test drive to verify the accuracy and reliability of the functionality.

proFRAME Provides a highly efficient video capture and playback system for synchronized playback of driving scenes in HiL systems, supporting the video streaming format of most current serializers such as GMSL and FPD-Link. The latest proFRAME 3.0 Equipped with two camera adapter slots, data rates up to 40 Gbit/s, and support for GMSL™3 and FPD-Link™ IV technologies, it allows simultaneous recording and playback of up to 8 channels of 4K video with precise control via timestamps or external triggers.

For HiL systems based on ROS or ADTF software platforms, proFRAME provides proprietary integration templates (ROS™ suite or ADTF plug-in) to quickly connect to the proFRAME software APIs for seamless integration with HiL systems, providing powerful support for testing and validation of driving scenarios.

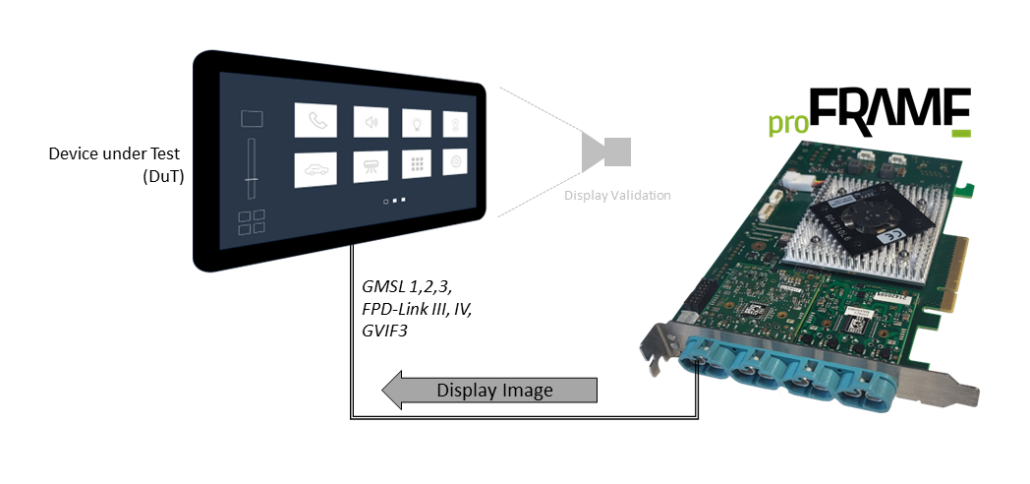

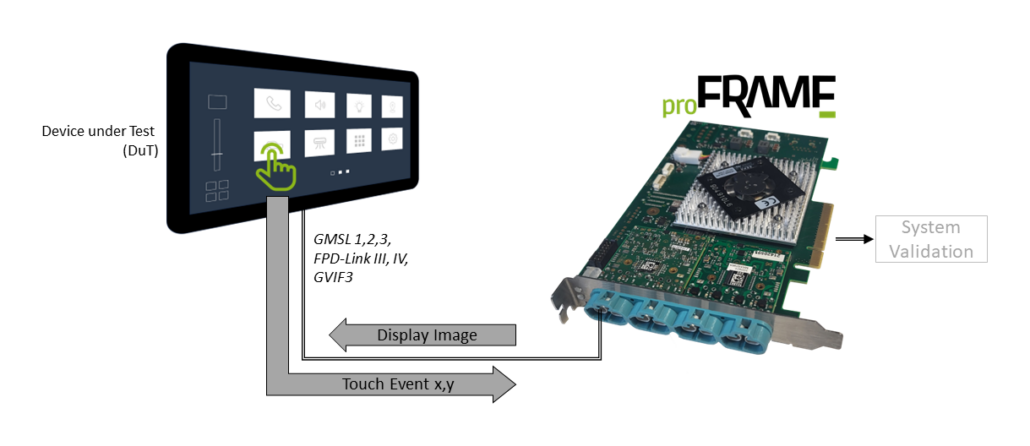

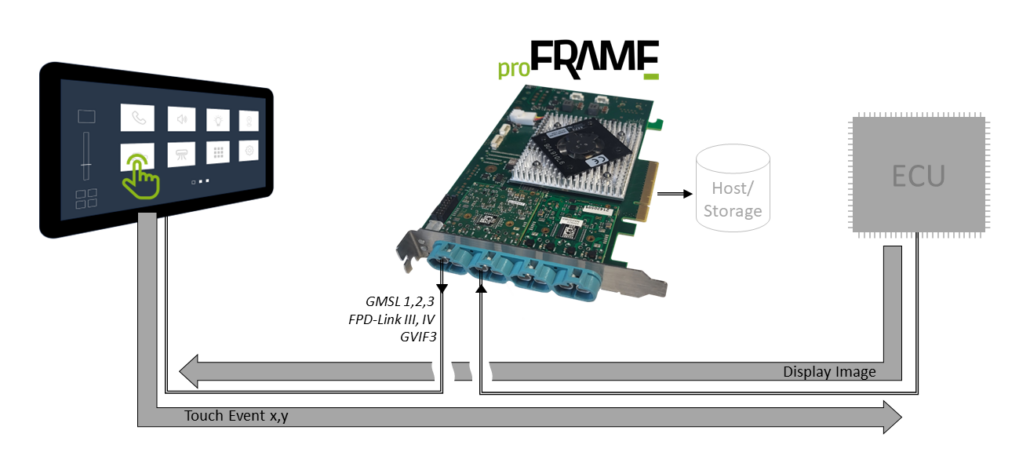

proFRAME with H-MTD® connector is used to calibrate and validate displays where video and control data is transmitted over STP cables (shielded twisted pair), such as HMI displays, rear-seat entertainment systems, or rearview mirror replacement system displays.

Typical display applications:

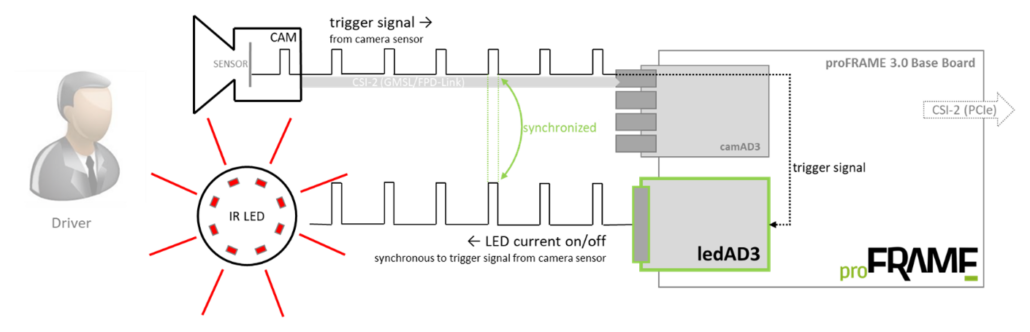

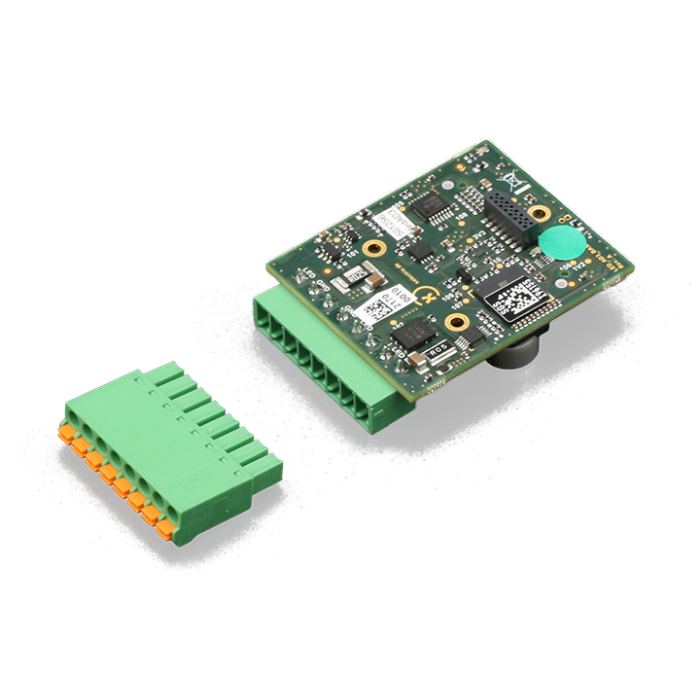

Drowsiness warning systems are now required by law in all parts of the European Union. With the aid of suitable accessories, proFRAME can be used for development and validation. With the LED driver adapter ledAD3, the user can choose to drive one or more LEDs during video data acquisition, e.g. LED. B. Synchronization with the camera's sensor exposure to control IR LEDs for indoor lighting. The LED driver adapter ledAD3 plugs directly into the proFRAME Baseboard 3.0, just like the camera adapter camAD3. The LEDs to be synchronized are connected to the ledAD3 using the supplied connector. The LEDs are powered by the ledAD3 via an adjustable constant current source, the output of which is switched by a trigger signal from the camera sensor, which is connected to the camera adapter on the same proFRAME Baseboard 3.0 (Fig. 1).

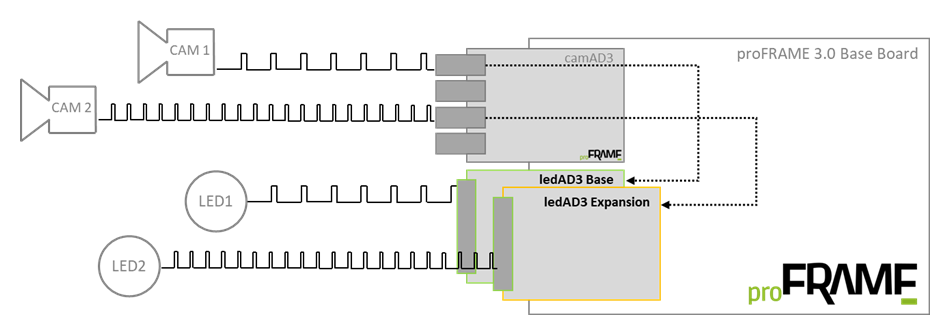

As an option to the ledAD3 Base, the ledAD3 Expansion module controls additional LEDs that are synchronized with the second camera's trigger signals. The ledAD3 Expansion plugs directly into the ledAD3 Base and therefore does not occupy any additional slots on the proFRAME Base Board 3.0. Thus, the complete system consists of the proFRAME Base Board 3.0, the camera adapter camAD3 as well as the ledAD3 Base and the optional ledAD3 Expansion. With such a system, the LEDs can be synchronized with one or two cameras (see Figure 2).

Plug-in program card with powerful FPGA functionality for real-time data processing and accurate time stamping, with proFRAME camera adapter slot for up to 8 cameras. Different adapters are supported depending on hardware generation and product variant.

3U CompactPCI® Serial (CPCI-S.0)

Baseboards built around AMD Zynq™UltraScale+™ ZU4CG MPSoCs that increase data acquisition rates up to 40 Gb/s per new camera adapter interface

PCIe® x8 Gen3 Interface (64 Gbit/s)

Baseboards built around AMD Zynq™UltraScale+™ ZU4CG MPSoCs that increase data acquisition rates up to 40 Gb/s per new camera adapter interface

The camera interface is included and mounted on the corresponding proFRAME substrate.

4 CSI-2® interfaces connected to the substrate

2 CSI-2® GVIF3 Serializers

2 CSI-2® GVIF3 Deserializers

2 Maxim CSI-2® GMSL2™ Serializers

2 Maxim CSI-2® GMSL2™ Dual Channel Deserializers

2 camera outputs, direct from ECU to camera. 2 x camera inputs, coaxial cable powered (PoC)

2 Maxim CSI-2® GMSL2™ Dual Channel Deserializers

4 Camera Inputs, Coaxial Cable Power (PoC)

2 Maxim CSI-2® GMSL3™ Serializers

2 Maxim CSI-2® GMSL3™ Dual Channel Deserializers

2 camera outputs, direct from ECU to camera. 2 x camera inputs, coaxial cable powered (PoC)

2 Maxim CSI-2® GMSL3™ Dual Channel Deserializers

4 Camera Inputs, Coaxial Cable Power (PoC)

2 MAX96705 (Maxim) CSI-2® GMSL1™ Serializers

2 MAX96706 (Maxim) CSI-2® GMSL1™ Deserializers

2 camera outputs, direct from ECU to camera. 2 x camera inputs, coaxial cable powered (PoC)

2 camera outputs, direct from ECU to camera. 2 x camera inputs, coaxial cable powered (PoC)

2 DS90UB953-Q1 (TI) CSI-2 FPD-Link III Dual Serializers

2 DS90UB954-Q1 (TI) CSI-2 FPD-Link III Dual Deserializers

4 Camera Inputs, Coaxial Cable Power (PoC)

2 DS90UB954-Q1 (TI) CSI-2 FPD-Link III Dual Deserializers

4 CSI-2® interfaces connected to the substrate

4 Camera Inputs, Coaxial Cable Power (PoC)

2 DS90UB9702-Q1 CSI-2® FPD-Link™ IV Quad Deserializer

4 CSI-2® interfaces to the substrate

1 DS90UB9702-Q1 CSI-2® FPD-Link™ IV Quad Deserializer

2 DS90UB971-Q1 CSI-2® FPD-Link™ IV Serializers

The user is able to control an LED that is synchronized with the triggering signal of a specific camera.

Controls the synchronized switching of LEDs for triggering signals from the second camera.

Enables proFrame to connect to a Thunderbolt 3 port on a PC or laptop.

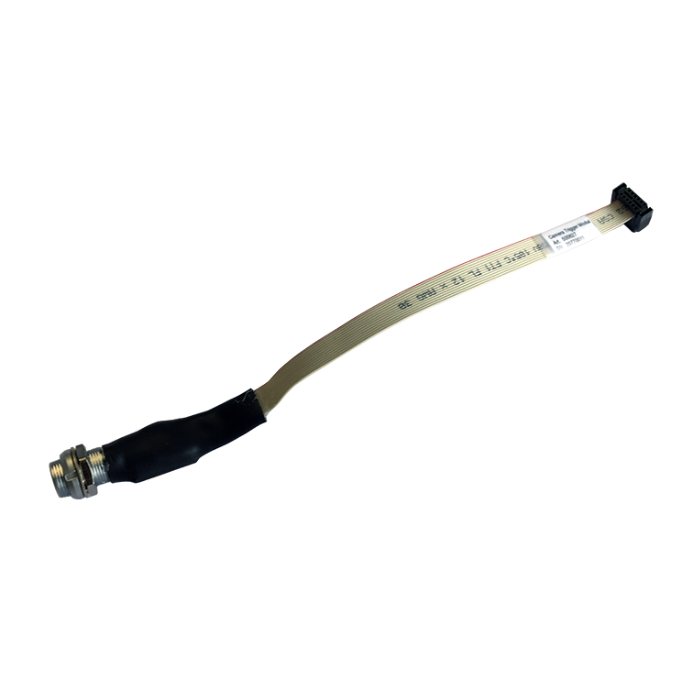

Synchronized signals for camera triggering from external triggering sources

Integrate proFRAME cards into your Windows or Linux® system.

Includes drivers and image sources for substrates, cameras, and sync adapters, GPU-accelerated software libraries for image signal processing capabilities, and a variety of simple sample applications for basic camera control

Focusing on the field of in-vehicle vision, covering a wide range of industries; based on application scenarios, solving niche needs. Honghong can also develop an integrated solution for your project, please contact us if you need.

Eight core advantages to create a new benchmark for machine vision.

Supports transmission technologies such as GMSL2™ and GMSL3™, FPD-Link™ III and IV.

Highly accurate real-time data processing, independent of other hardware requirements

Flexible switching of various operating modes, utilizing FPGA logic to realize internal system programming.

Data offloading without CPU intervention greatly improves data transfer efficiency and speed.

RAW video data recording and playback based on high-precision time stamping

Delivery of I2C messages independent of the ECU to multiple connected cameras

Each substrate can be synchronized with multiple cameras, supporting multi-substrate operation and realizing up to 8 streams of data processing.

Adjust the frequency and parameters of the graph clock according to specific needs.

- MaxicoM: GMSL2™ and GMSL3™

- TI: FPD-Link™ III and IV

- Sony Semiconductor: GVIF (other technologies available upon request)

proFRAME supports synchronization of multiple cameras per substrate as well as synchronization of multiple substrates. With the proFRAME SYNC adapter, synchronization signals for camera triggering can be taken from an external trigger source and generated on our proFRAME boards. These signals can be sent to the camera or to an external trigger receiver. The adapter is available as input/output and dual input.

As proFRAME has the ability to capture, replay and process raw video data streams in a variety of applications. The system is used in the automotive field to validate ADAS systems, hardware in-situ testing or autonomous driving functions. proFRAME is also used in industrialized applications in medical technology, digital microscopy (e.g. sinaSCOPE, a 3D digital microscopy platform) and end-of-line testing.

You can contact our staff with project information and our machine vision team will provide you with professional selection services.

Our professional Honghong team will be the first to respond and provide you with the best service to solve all your problems.

Address: 3F, No. 99, Jingye 1st Road, Zhongshan District, Taipei City, Taiwan (Da Wan Technology Center Building)

3rd Floor., Dawan Technology Center Building, No. 99 Jingye 1st Road, Zhongshan District, Taipei City, Taiwan

©2025.hongtronics. All Rights Reserved.