I. Case background

A chemical manufacturer has multiple plants internationally, but the current out-of-control action plans (OCAPs) used in the production process are still based on paper records and processes. These plans were cumbersome and time-consuming, negatively impacting production. In addition, the paper-based SOPs, which consisted of about 100 pages, needed to be followed for each order, and the cumbersome procedures resulted in a high error rate, creating safety and regulatory risks if additives were mixed in the wrong order or in the wrong quantities. The company therefore needed to digitize and automate its production processes. In the process of digital transformation, the first problem was:

● Paper SOPs are cumbersome for operators to keep and are often overlooked and lost.

● Version control of SOPs for multiple locations.

● Safety incidents, scrap and errors are on the rise as experienced employees retire.

● Highly manual processes make regulated tracking and tracing of each step in the chemical production process difficult and inconsistent.

● Operators need to log into multiple different systems to get the information they need and record transactions, resulting in reduced efficiency and impacting production.

:: Reduced safety incidents and improved compliance through automation and guidance.

II. Solutions

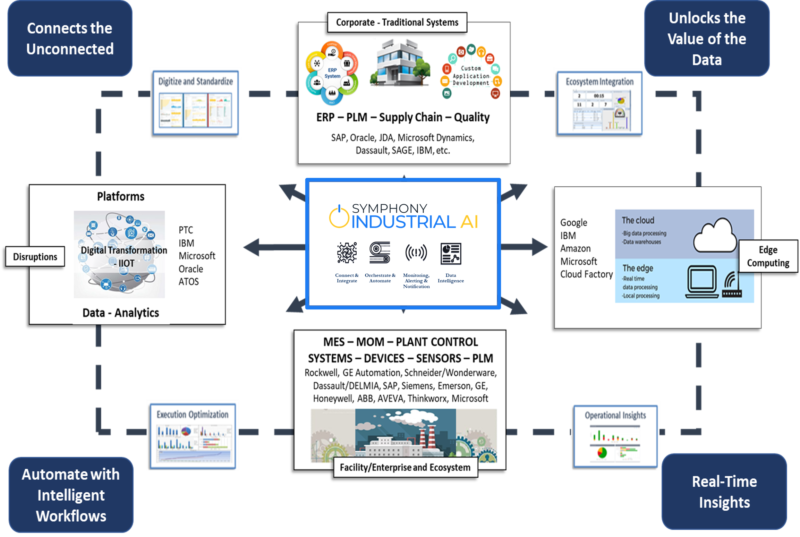

The customer used the SIAI platform to connect systems, tools and history to automatically collect, store, monitor and track events. This increased operator productivity, reduced downtime and errors, and automated the OCAP process. Key initiatives include:

● Created and implemented a digital SOP solution in eight weeks using the Savigent platform, which was then rolled out across six plants.

● Configured intelligent workflows for non-IT engineers to guide the execution of role-based step-by-step instructions.

● The solution includes automated material validation, confirming that critical steps are completed in the correct sequence and ensuring that equipment is locked out during replacement and cleaning.

● The system alerts the operator in real time via tablets and other devices when an action or deviation is required.

efficacy

The client adopted our predictive maintenance solution, in which we provide an artificial intelligence platform to automate operations and guide work, reducing safety incidents, improving compliance, and moreover, increasing production and improving the efficiency of production line applications. By consolidating the number of system interfaces and eliminating the use of paper, it improves operator efficiency, shortens the learning curve and ramp-up time for new employees, and ensures that they can get up to speed in the shortest possible time.

Glossary of Terms

1. Out-of-Control Action Plan (OCAP)

Out of Control Action Plan (OCAP) is an important element / document in the Total ControlMethodology advocated by Motorola, OCAP is a powerful tool that collects the technical knowledge and experience of engineers, making it easy for all line staff to acquire the problem-solving skills. skills. OCAP includes.

Decision tree in process mode

Explain in detail all the diagnoses of symptoms and corrective actions taken in the event of a loss of control.

2. Standard operating procedures (SOPs)

Standard Operating Procedure (SOP), refers to the standard operating procedures and requirements of an event described in a uniform format, used to guide and standardize daily work. The essence of SOP is to quantify the details, in layman's terms, SOP is the key control points in a procedure to refine and quantify. The core of SOP in the actual implementation process is in line with the enterprise and can be implemented, not in form.

Contact Us