With the ever-changing automotive technology today, if you don't work hard and learn, you may be eliminated from the industry tomorrow! Come together to understand new technologies, use new tools, develop new ideas, and strive to be an automotive diagnostician who keeps up with the times! --Mr. H

What is a SENT signal?

In previous vehicles, most sensors transmit analog signals. Analog signal is easy to measure, the signal voltage change reflects the change in physical quantities, the use of multimeter voltage stops can be measured to this change, such as sliding resistance throttle position sensor, when the throttle flap position changes, the sliding resistance changes, the signal voltage due to resistive voltage divider and changes occur.

Overall, some of the sensors simulate the signal voltage is changed with the specific resistance changes, such as reflecting changes in the position of the throttle position sensor, accelerator pedal position sensor, body height sensors, etc. using sliding resistance, reflecting changes in the pressure of the intake manifold absolute pressure sensors, pressure sensors, oil rail pressure sensors, etc. using a piezoresistive resistor, reacting to changes in temperature intake air temperature sensor, The inlet air temperature sensor, engine coolant temperature sensor, etc. use thermistor.

As shown in Figure 1, start the engine, the engine speed (mathematically calculated from the crankshaft position sensor signal) increases, the absolute intake manifold pressure (reflected by the voltage on the absolute intake manifold pressure sensor signal line) decreases, and a vacuum is formed; depress the accelerator pedal, the throttle opens (the throttle position signal is reflected by the voltage on the throttle position sensor signal line), and the absolute intake manifold pressure rises, and the vacuum is formed; depress the accelerator pedal, the throttle opens (the throttle position signal is reflected by the voltage on the throttle position sensor signal line), and the vacuum is created. The absolute pressure in the intake manifold rises and the engine speed increases. The whole process can be clearly seen by the waveform of the simulated signal.

Fig. 1 Engine RPM, Absolute Pressure of Intake ManifoldSignal waveforms such as throttle position (screenshots)

However, the analog signal is susceptible to interference, to the module internal still have to go through the analog-to-digital conversion, prone to signal deviation, resulting in inaccurate control of the engine, while the digital signal has a strong resistance to interference, communication speed, analog-to-digital conversion in the sensor internal completion. So for some of the higher rate of change of the signal, as well as more important signals, such as air flow signals, the first to use the frequency of the digital signal transmission.

With the development of science and technology, the signal reliability requirements are getting higher and higher, especially the pressure signal feedback, such as the absolute pressure of the intake manifold, high pressure oil rail pressure, etc., the more accurate and fast feedback, the more favorable to the engine control, so the pressure class sensor signal transmission, in many car models use a new technology - SENT (single-sided byte) signal, which is a communication digital signal. -SENT (Single Edge Half Node) signal, which is a communication digital signal.

The sensor using SENT signal only needs 3 wires, 1 power wire, 1 lap wire and 1 SENT signal wire, SENT signal is unidirectional communication, i.e., the sensor can only send data, but multiple data can be sent through this one communication wire, e.g., an air flow sensor can send air flow and intake temperature signals through the SENT signal wire, a throttle position sensor can send 2 position signals through the SENT signal wire, and so on. For example, an air flow sensor can send air flow and intake air temperature signals over the SENT signal line, a throttle position sensor signal can send two position signals over the SENT signal line, etc. Conventional throttle position sensor (Figure 2a) inside the two position sensors share a power cable and a hitch wire, each has an independent signal line, a total of four wires, while the new throttle position sensor (Figure 2b) inside the two position sensors in addition to sharing the power cable and hitch wire, but also a common signal line, that is, through a SENT signal line can send the signals of the two position sensors, so that it is possible to send the signal of the two position sensors, so that it is possible to send the signal of the two position sensors through the SENT signal line, so that it is possible to send the signal of the two position sensors through the SENT signal line. In other words, the signals of two position sensors can be sent through one SENT signal line, thus saving one signal line.

Figure 2 Throttle Position Sensor Circuit

The SENT signal line of the sensor transmits high-speed coded information (Fig. 3), and the data is updated once in a few hundred μs, which is a sufficient refresh rate for simulating changes. In addition, SENT signals have the advantage of low cost and reduced wiring, while digital signals greatly improve the reliability of signal transmission and interference resistance. More and more analog signals will be replaced by SENT signals, high-pressure oil rail pressure sensors, intake manifold absolute pressure sensors, air flow sensors, throttle position sensors, etc. are gradually used SENT signals, which brings new challenges to the maintenance and diagnosis.

Figure 3 SENT Signal Message Format

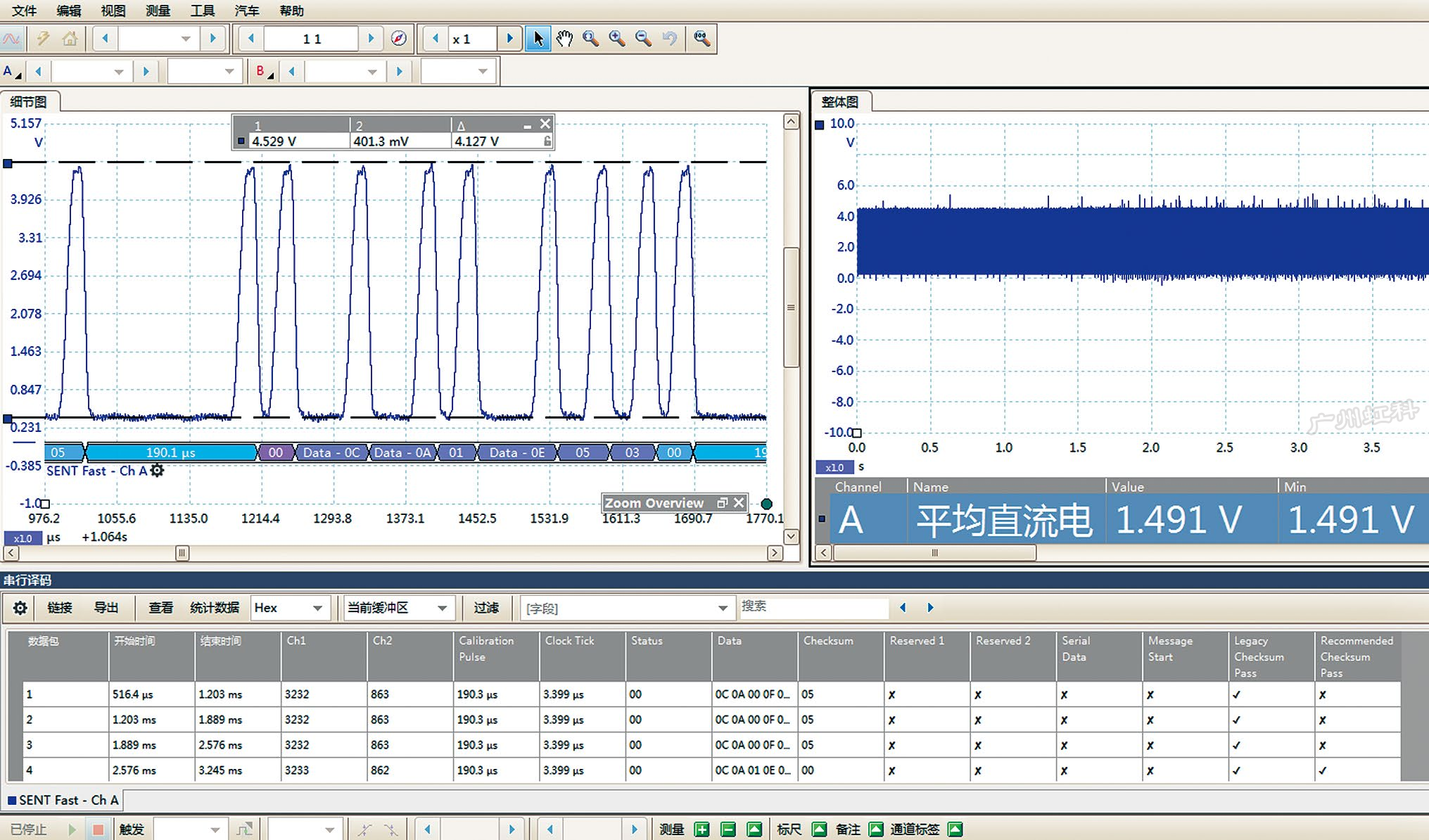

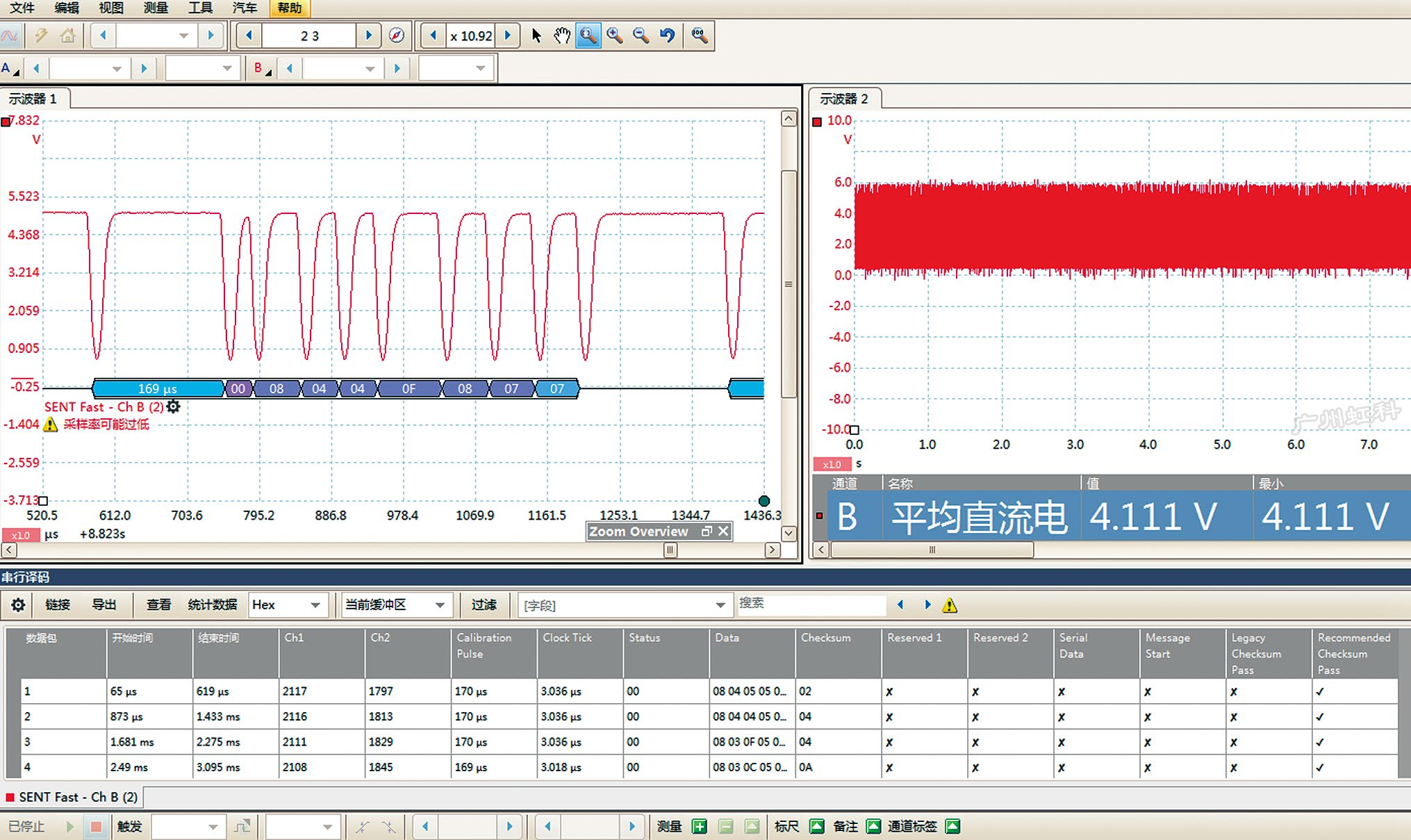

In maintenance practice, the author used a multimeter to measure the SENT signal voltage of 1.5 V and 4.1 V two kinds (Figure 4 shows the Buick Verano car throttle position sensor SENT signal line communication waveform, the average voltage is about 1.5 V, Figure 5 shows the Volkswagen Touguang car high-pressure oil rail pressure sensor SENT signal line communication waveform, the average voltage is about 4.1 V), the signal Voltage does not change with the changes in the physical quantity being measured, so in the maintenance and diagnosis, can not be measured through the use of a multimeter voltage changes to determine the good and bad sensor, and even more can not be sent through the analog voltage signal to test whether the control unit is normal, this operation is easy to make the control unit of the internal chip damage.

Fig. 4 Communication waveforms (screenshots) on the SENT signal line of the throttle position sensor in the Buick Veracruz

Fig. 5 Communication waveforms (screenshots) on the SENT signal line of the high-pressure rail pressure sensor of the Volkswagen Touareg

Contact our engineers for more information about Pico auto's SENT signal! We are here to help you learn more about our tools!