Failure phenomenon

A 2010 Rolls-Royce Ghost with N74 engine and about 110,000km.The owner reported that after starting the engine, the combination meter and the central information display popped up the warning of "transmission failure" at the same time.He is quite worried about this.

First image, 2010 Rolls-Royce Ghost.

Fault Diagnostics

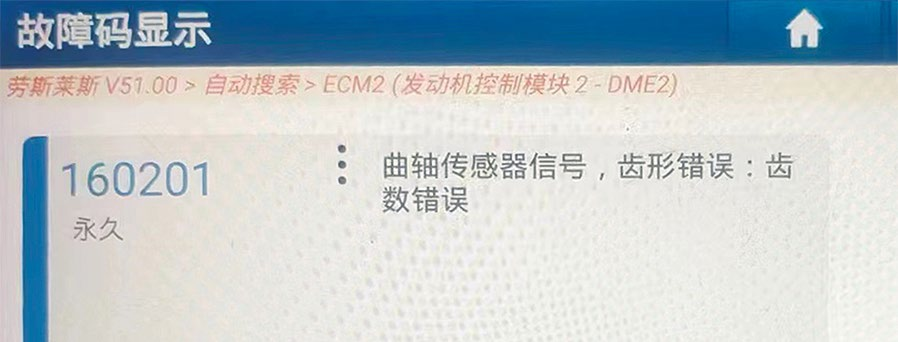

After troubleshooting through the fault detector, it was found that the Engine Control Module 2 (DME2) stored the fault code "160201 Crankshaft Position Sensor Signal, Tooth Shape Error: Wrong Number of Teeth" (see Figure 1).Repairers checked the power supply, iron and signal lines of the crankshaft position sensor and replaced the sensor, but could not solve the problem.The cause of the malfunction was at a standstill for a while.

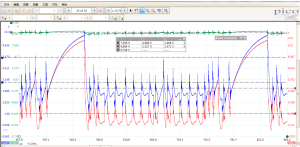

Fig. 1 Fuel Pressure Data Flow of the Faulty Vehicle with Engine Starting

Upon in-depth inspection, it was found that, as shown in Fig. 2, theThe crankshaft position sensor has three wires: the power wire, the iron wire, and the signal wire, which is shunted to DME1 and DME2 at the same time.However, the test results showed that there was no fault code for DME1, except for DME2, which showed "160201 crankshaft position sensor signal, tooth shape error". However, the test results showed no fault codes for DME1, but only "160201 Crankshaft Position Sensor Signal, Gear Shape Error" for DME2. It was further found that DME1 was still able to read the engine speed, while DME2 was unable to obtain this critical data.

Fig. 2 Crankshaft Position Sensor Circuit

In order to confirm whether there is any signal line or iron override abnormality, the technician first disconnects the crankshaft position sensor wire connector X6203 and measures it with a multimeter:

- Terminal 1 to housing voltage: 12.5 V (normal)

- Terminal 3 to housing voltage: 4.7 V (normal)

- Resistance of terminal 2 to the engine case: 120 Ω (suspected to be a defective iron)

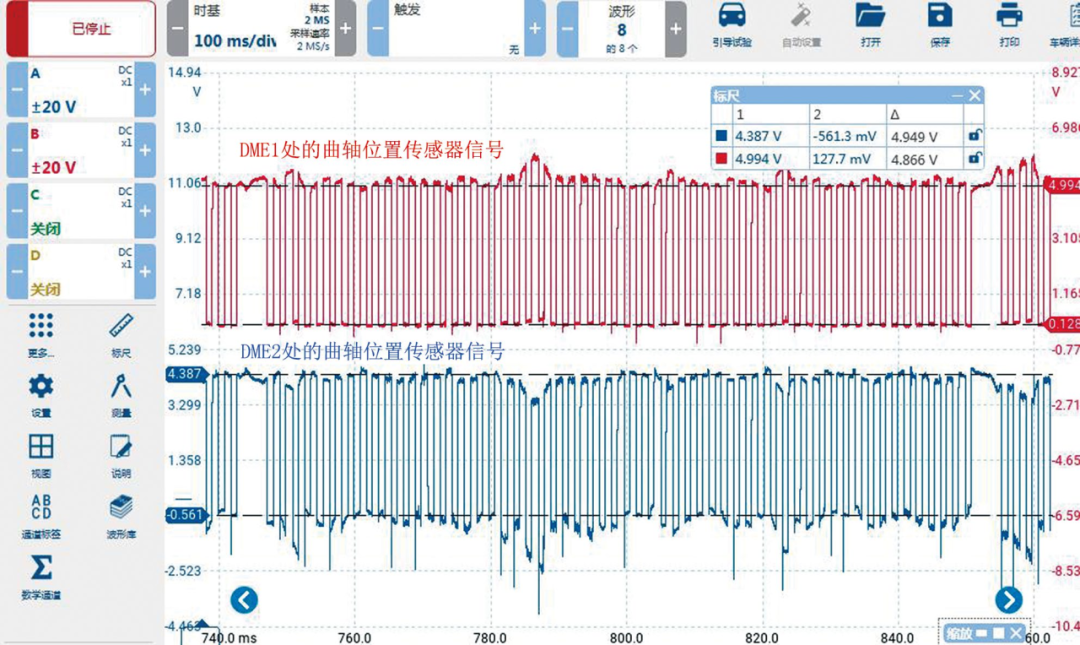

Even if you try to ground terminal 2 directly, the problem is still not solved.The results showed that the signal of DME1 was stable and high. So, we used the Honghong Pico automotive oscilloscope to synchronously measure the crankshaft position sensor signal waveforms at DME1 and DME2 (see Fig. 3), which showed that the DME1 signal was stable, with a high level of about 4.9 V and a low level of about 128 mV, while the DME2 signal had a high level of only about 4.3 V, and the low level was fluctuating under 0 V, which showed that the signal quality was obviously out of the normal range.

Fig. 3 Crankshaft Position Sensor Signal Waveforms at DME1 and DME2 during Failure

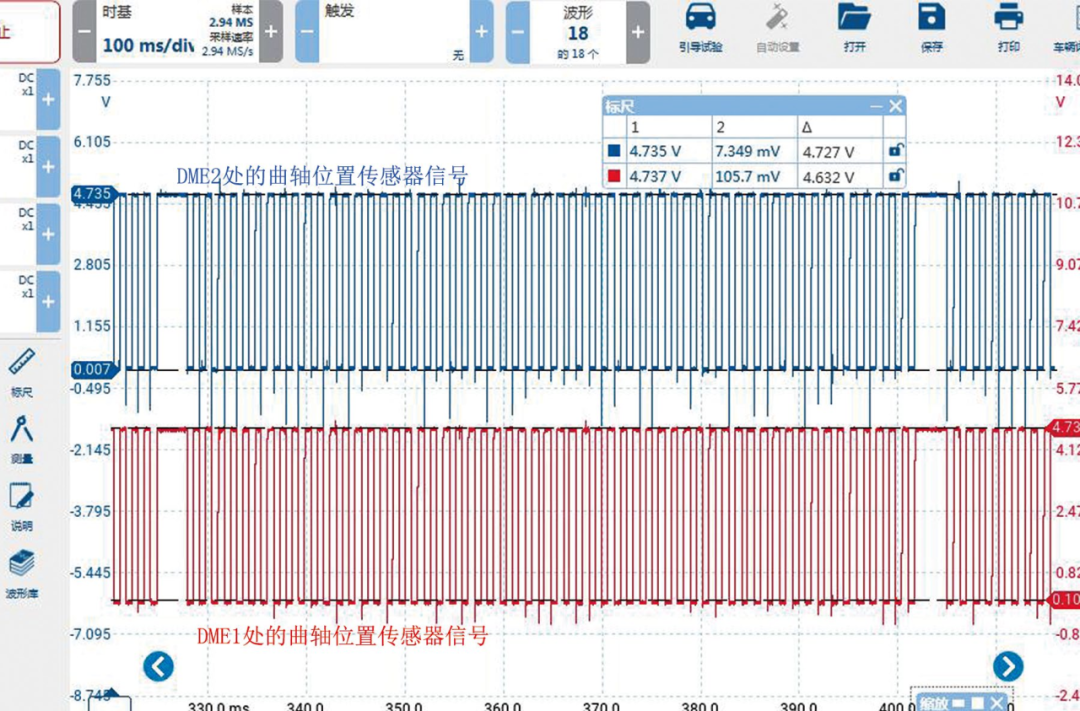

Further measurements: DME1 Lead Connector X60004 Terminal 11 approx. 0.002 V to the laptop, DME2 Lead Connector X20004 Terminal 11 approx. 0.909 V to the laptop.This shows that there may be a problem with the DME2's internal iron circuit.After comparing the part numbers, try to install DME1 and DME2 in counterbalance. After comparing the part numbers, I tried to install DME1 and DME2 in pairs, and immediately found that the problem disappeared, and the signal waveforms read by both of them returned to normal (see Figure 4).

Fig. 4 Crankshaft position sensor signal waveforms at DME1 and DME2 during normal time.

fault resolution

After further inspection of the DME2 lead connector X20004 terminal 11, although there was nothing out of the ordinary in appearance, the tightness test showed that the terminal was indeed loose. After replacing the terminal, the vehicle was tested again and the problem was completely eliminated. The vehicle was driven for about a week and the owner reported no further abnormalities.

Fig. 5 Test the tightness of DME2 wire connector X20004 terminal 11.

Fault Summary

This case reconfirms that while the vehicle fault code refers directly to the crankshaft position sensor, the actual root cause is not necessarily the sensor itself.Vehicle control modules are interlocked. Vehicle control modules are interlocked, once a terminal or a latch is loosened, it will trigger a signal abnormality and lead to a misjudgment of the system. If you only focus on the components that the code points to, it is often difficult to solve the problem even after replacement.

Oscilloscope measurements accurately reproduce signal quality and highly reproduce waveform characteristics at the time of the fault.It provides a reliable basis for technicians to determine circuit and module abnormalities. When the basic test is not obvious, it is recommended to combine the maintenance manual with the replacement test method to find the real failure point, so as to achieve more efficient and accurate maintenance results.

Product Recommendation

.webp)

Pico4425A 4-Channel Standard Package (EP032)

- Meet the needs of general automotive diagnostics at an affordable price.

- Supports a wide range of sensors to easily capture all kinds of signals

- High-speed sampling to quickly pinpoint the root cause of a problem.

- Professional training and application examples to get started quickly

Pico4425A 4-Channel Advanced Package (EP034)

- Higher hardware specifications for complex maintenance environments

- Complete measurement functions with high-grade probes and accessories

- Assistive software provides in-depth data analysis and reporting

- Widely used in high-end automotive repair and modification scenarios