Reed relays

Reed Relay Principle

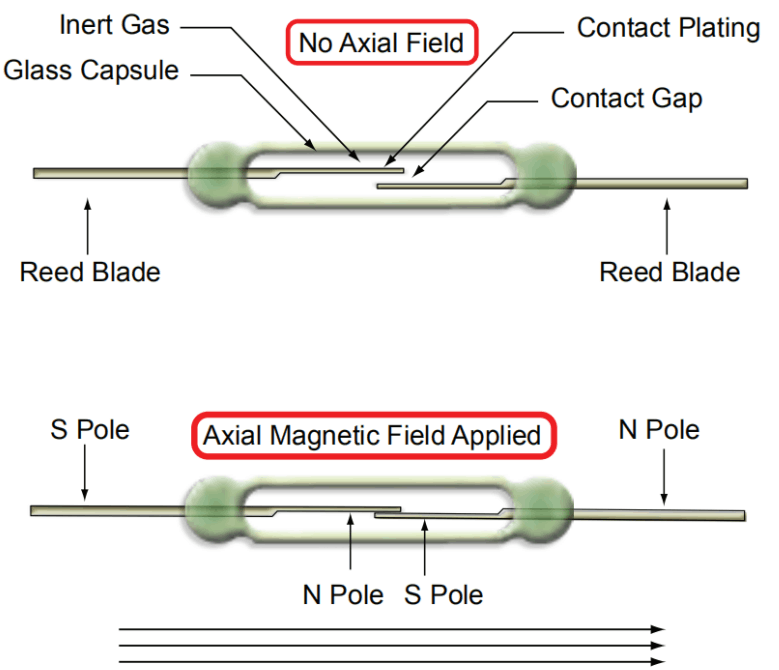

The principle of reed relay seems very simple, the core action device of reed relay consists of two pieces of ferromagnetic material reed and sealed glass tube composed of reed, generally speaking, the composition of the reed is nickel: iron = 50 :50. The metal sealed tube will usually be filled with inert gas, isolation of the external environment of the pollutants and oxygen, which can effectively prolong the use of the life of the contacts. Generally speaking, reed switches are normally open, but there are also normally closed versions.

As shown in the figure below, if a magnetic field is applied along the axis of the reed, when the field increases to a certain strength, the reed will become magnetic due to the ferromagnetic effect, and the two contacts will be sucked together to energize both ends. As shown in the figure below, if a magnetic field is applied along the axis of the reed, when the magnetic field increases to a certain strength, the reed will become magnetic due to the ferromagnetic effect and the two contacts will be attracted together to energize both ends.

Construction of Magnetic Fields

To close the reed switch, an external magnetic field needs to be established. Some reed switches are used in combination with permanent magnets as proximity switches or to detect the opening or closing of doors or windows and other positional information. But for the reed relay, the magnetic field required to close the contacts is generated by the coil, which realizes the function of controlling the contacts to close or break by controlling the full current of the county. As shown in the figure, the coil is wrapped around the outside of the glass tube of the reed switch to provide an axial magnetic field.

Different reed switches require different magnetic field strengths, this indicator is generally expressed in terms of “magnetic potential”, which is measured in AT (ampere-turns), simply understood as the product of the current flowing through the coil and the number of turns in the coil. This leads us to the characteristics of reed relays. Generally speaking, the more power or voltage a reed has to carry, the harder and more widely spaced the reeds are, which means a higher magnetic potential is required, and so the more power the relay coil has to carry.

Magnetic field shielding

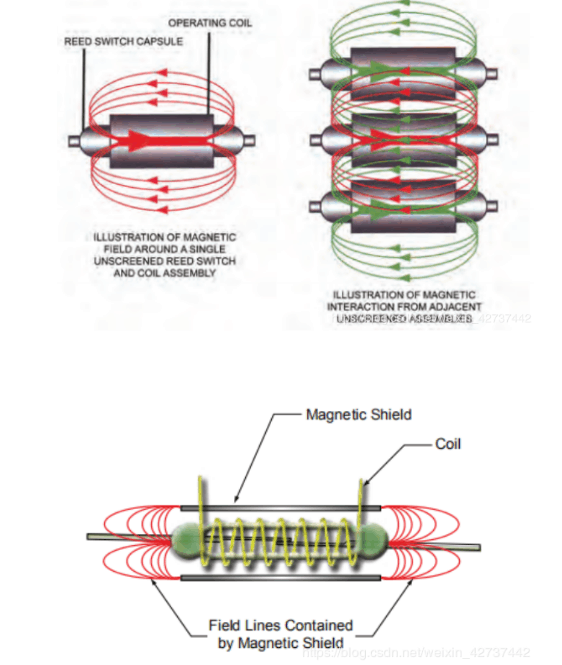

Since the reed relay is driven by a magnetic field, this brings some hidden dangers. First of all, we need to understand a concept, the magnetic field formed by the coil is a closed loop, that is, the magnetic field through the reed of the reed switch, the return from the outside, that is, in the space outside the coil there will also be a magnetic field, and the magnetic field can be superimposed. When the reed relay needs to be in the PCB in a dense arrangement, due to the different magnetic fields will be superimposed on each other, in part of the region is the state of strengthening, and in another part of the state of weakening, which will lead to a part of us do not want to let the closed reed relay closed by itself, and another part of the relay we want to close due to the magnetic field due to the superposition of the weakening of the cause of the failure to close, which results in a serious interference phenomenon, which will lead to a serious interference phenomenon. This caused serious interference and prevented the equipment from functioning properly. Some relay manufacturers suggest avoiding this situation as much as possible by arranging the relays in different polarities, but this means that the user must take into account the interference of the magnetic fields, and it adds a lot of mechanical design trouble for large-scale intensive use of the relays. Another method is to increase the magnetic shielding in the outer shell of the relay, which will isolate the magnetic field leakage, then the user can be free to layout, do not need to consider the mutual interference between the relays.

Material and mechanical life

The most reliable construction of reed relays is the Single Piece Single Throw (SPST) switch (FormA). The SPDT switch (FormC) usually has a shorter life than the SPST due to technical difficulties in manufacturing and product tolerances. If a longer life SPDT is desired, it is necessary to consider combining two SPST relays into one SPDT relay. The life of reed relays is generally very long, with Pickering's relays for small and medium current applications reaching 9 times 10. The contacts of the reed relay are sealed with glass tubes, which are filled with inert gas or pumped into a vacuum, so they do not come into contact with external contaminants, and precious metal materials are used on the contacts, and the only moving part in the whole device is the deflection of the reeds, with no rotating shafts or sliding parts, which makes it have a very long service life and does not cause direct contact with the outside world of the phenomenon of arcing sparks and so on, so it can be used in some safety requirements. Therefore, it can be used in some occasions with higher safety requirements.

Precious metal coatings on contacts play a critical role in the performance of relays. Some of the best plating properties reduce the corrosion of relays during thermal switching. The most commonly used contact materials are ruthenium, rhodium and platinum - these are relatively rare platinum group precious metals. Tungsten is usually used as contact for high power or high voltage reed relays because of its extremely high melting point. Different relays for different applications are plated with different layers of tungsten on the contacts according to the requirements. The layer of tungsten has a great influence on the performance of the relay and also on the cost of manufacturing the relay. Reed relays are classified into different grades according to their cost and performance. Low quality commercial relays use rhodium contacts, which are in fact less suitable for switching smaller signals due to the formation of a polymer film on the contacts. Sputtered ruthenium contacts are generally more suitable for switching low level signals and do not suffer from the same polymer film problem as relays with rhodium contacts. If the application requires low level signal switching and quality is important, instrumentation grade ruthenium reed relays are undoubtedly a better choice.