preamble

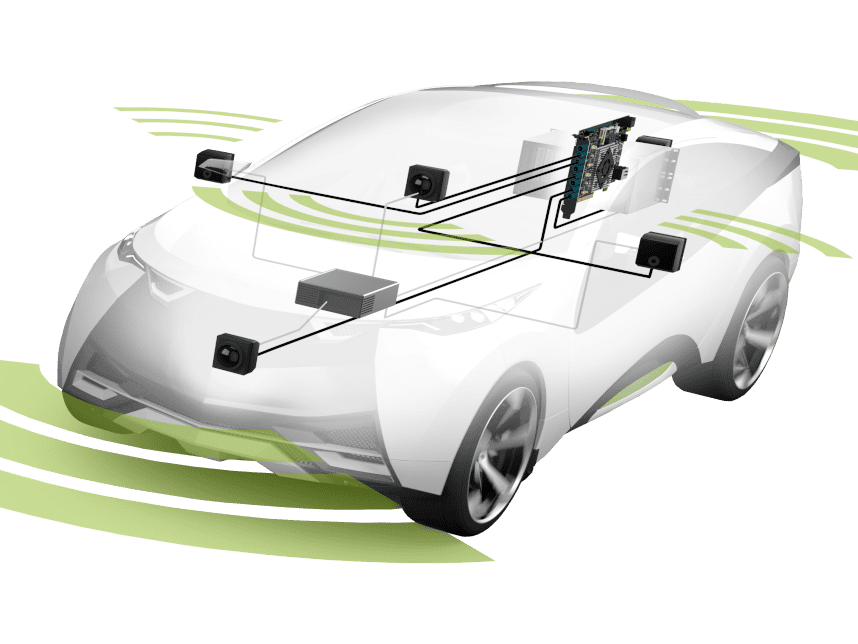

Intelligent driving and autonomous driving technologies are gradually developing and maturing.Vehicle-mounted multi-phase machine sensing systemIt has become a central key to vehicle safety and environmental recognition.

Multiple in-vehicle cameras capture video data from different angles, enabling the vehicle to obtain more complete environmental information to help complete theLane Detection, Object Recognition, Pedestrian Alert, Traffic Sign RecognitionIt provides a key visual foundation for self-driving and ADAS systems.

However, if multiple camerasLarge Time Synchronization Offset will cause the image data to be misaligned on the time axis, which will seriously affect the accuracy of the image fusion and decision-making algorithms.。

In response to this challenge, Honghong has teamed up with Solectrix of Germany to launch a new product, "The Newest and Most Innovative Products in the World". proFRAME Modular Image Acquisition and Injection BoardsProvide DodaFive microsecond synchronization schemesIt helps the in-vehicle imaging system to achieve high-precision time alignment during the R&D and testing phases to ensure the stability and safety of intelligent driving.

I. Technical Background

In the age of smart cars and autonomous driving.Multi-Camera System (Multi-Camera System) It is the basis for realizing environmental awareness.Multiple in-vehicle cameras are required to simultaneously capture environmental images and performImage Fusion and Time SynchronizationThis is to ensure that ADAS or self-driving algorithms can read the scene at the right time.

Since each camera has different sensors, image processing processes and transmission delays, failure to achieve precise synchronization may result in misalignment of visual perception, fusion errors and delays in judgment, and ultimately, in the end.Impacts on Vehicle Decision Making and Driving Safety。

proFRAME Modular Image Acquisition and Injection BoardsIt is designed to solve this problem by supporting multiple clock source synchronization methods to achieveMicrosecond time calibrationIt meets the needs of applications such as in-vehicle imaging systems, ADAS, domain controllers and HiL (Hardware-in-the-Loop) test platforms.

Second, proFRAME high-precision time synchronization five solutions

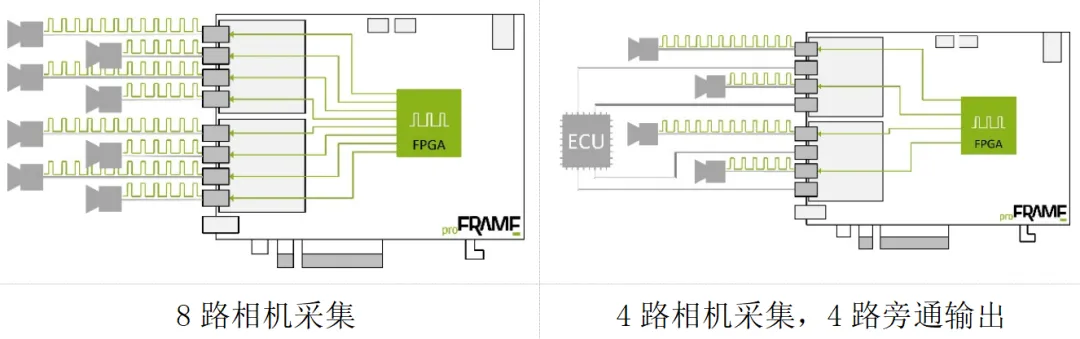

1. Baseboard FPGA Clock Signal Trigger Synchronization

FPGA generation for proFRAME boards 40 MHz clock signal (25ns interval)The image is captured and injected into the image, and each frame can be labeled with theNanosecond time stamp (Timestamp)。

All connected cameras are triggered with this unified clock signal to realizeMicrosecond multi-phase machine synchronizationThis ensures consistent image timing and provides an accurate basis for subsequent image fusion and perceptual algorithms.

2. Synchronization of phase pulse signal triggering

Some cameras support a built-in Trigger Pulse output, which can be used as a clock source for multiphase synchronization.When the main camera outputs a pulse signal, it is transmitted to the proFRAME FPGA via a coaxial cable, and then the FPGA distributes it to the other cameras, so that all the camerasActivate video capture at the same moment.It is also effective in minimizing time deviation.

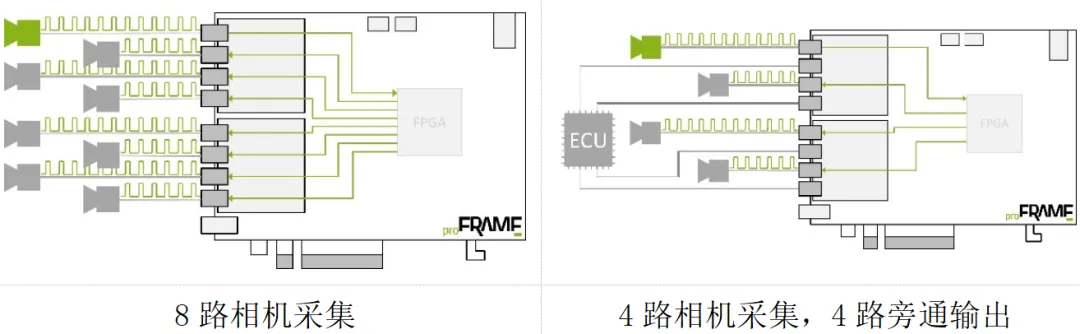

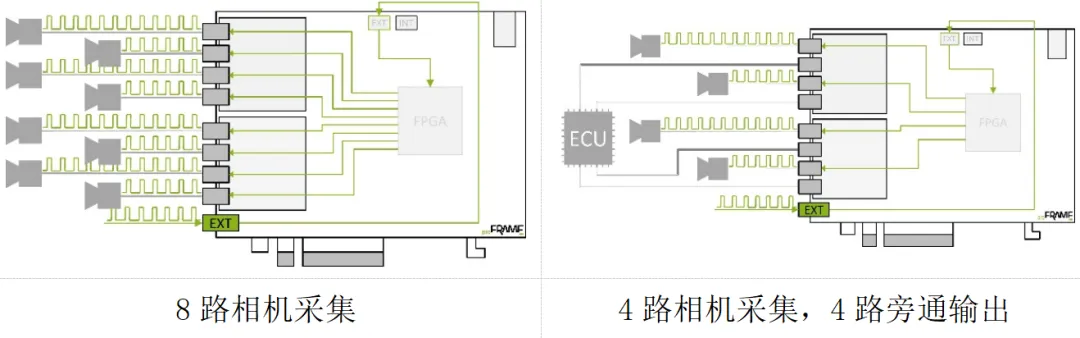

3. External Trigger Synchronization

The proFRAME boards also support the use of other sensors (e.g., LiDAR, millimeter wave radar, IMU, GNSS, etc.).Cross-module time synchronization。Trigger signals from external devices can be distributed to multiple cameras through the board to realizeUniform time reference across sensorsThis ensures that heterogeneous perceptual data remains highly consistent when fused.

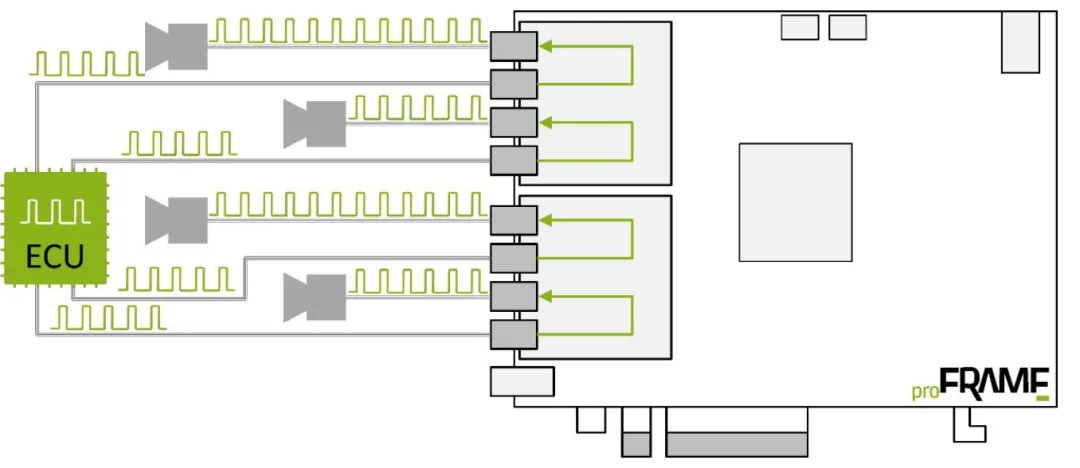

4. ECU bypass trigger synchronization

proFRAME SupportReal-time collection and bypass output mode (Bypass Mode)The video data can be output to both the host and ECU/Domain Controller at the same time.

The ECU can also send back the triggered clock signal through the reverse control channel to realize two-way time synchronization between the ECU and the camera, ensuring that the data stream (Video Stream) and control signals (I2C, GPIO) are fully aligned.

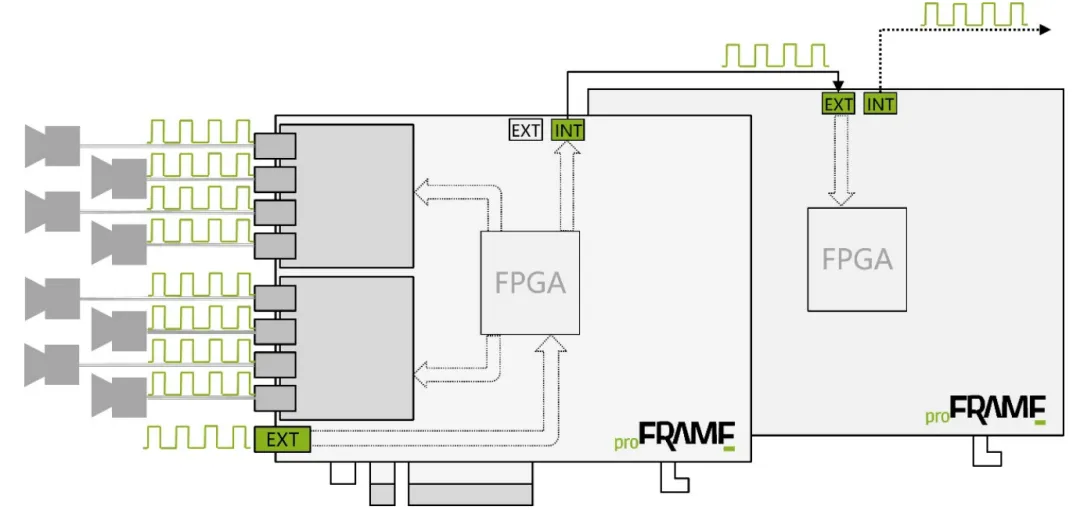

5. Time synchronization between multiple boards

When more than 8 cameras are required for a video system, proFRAME supports multi-card linkage.Board-to-Board Internal/External Trigger Interface Shared FPGA clock signals to enableMulti-card synchronized triggeringThis ensures that the time error between all cameras is maintained at the microsecond level.

Program testing and validation

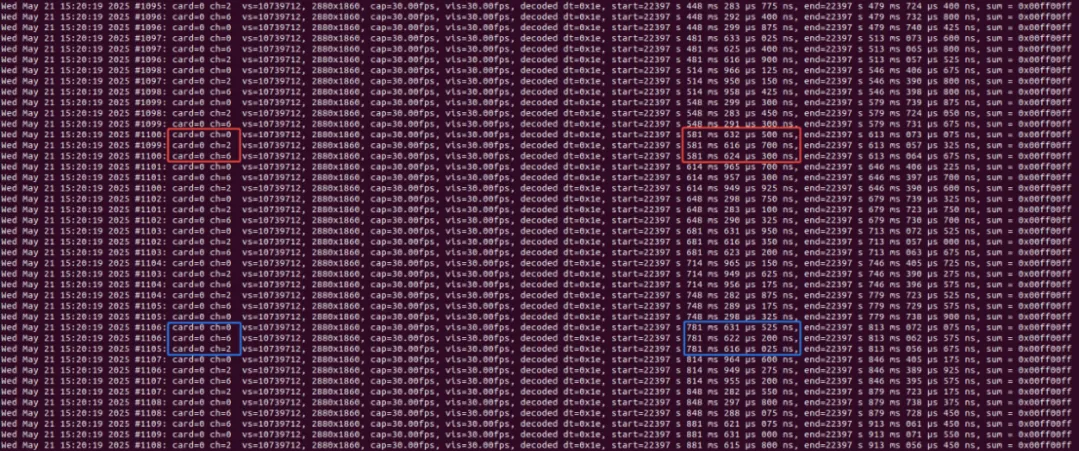

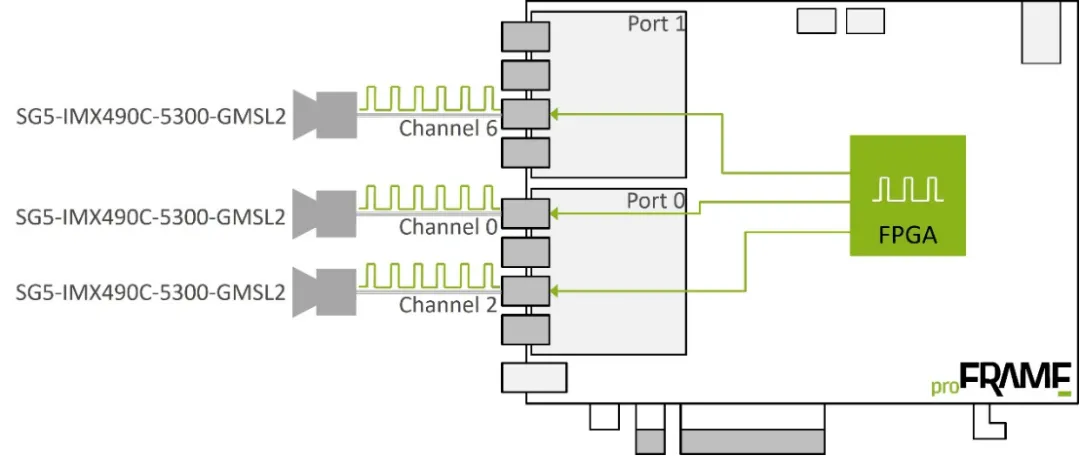

1. Three-camera time synchronization and image acquisition test

The proFRAME board connects to three Senyun cameras, model SG5-IMX490C-5300-GMSL2 (resolution 2880×1860, sample rate 30fps).The system is triggered by the FPGA clock signal built into the card to synchronize the exposure and image acquisition process of the three cameras.

- The test results are as follows:

Synchronized triggering and exposure activation of the three cameras through the proFRAME card to successfully capture the image data.

As shown by the red and blue lines in the figure (the left side represents the acquisition channel, and the right side is the nanosecond time stamp of the current image frame), the time synchronization error among three cameras is as followsApprox. 15 microseconds (µs)The overall synchronization accuracy of the display is very high, which is sufficient to meet the experimental requirements of multi-phase machine perception and image fusion.

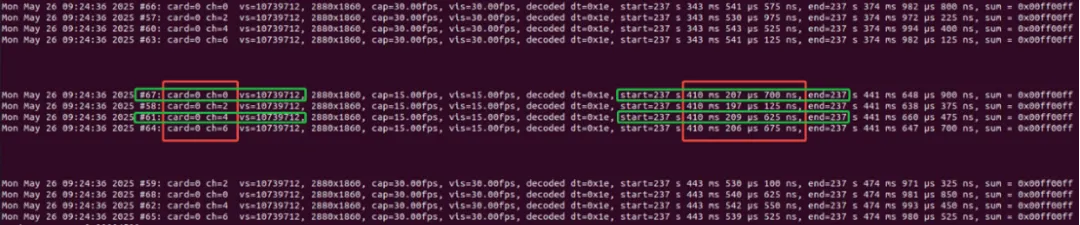

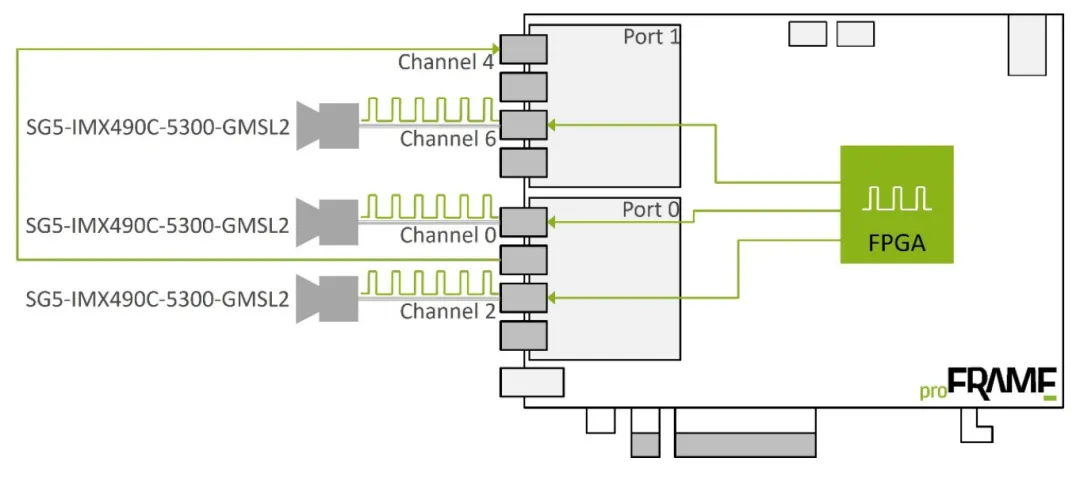

2. Three-camera synchronization and bypass image acquisition test

The proFRAME board connects three Senyun cameras, model SG5-IMX490C-5300-GMSL2 (resolution 2880×1860, capture rate 30 fps). The system triggers the synchronized exposure and image acquisition of the three cameras through the built-in FPGA clock signals on the board. At the same time, the bypass output signal of Channel 0 is connected to Channel 4 for acquisition to verify the bypass data content and time delay performance.

- The test results are as follows:

The proFRAME card triggers the three cameras to synchronize to start exposure and acquire image data, as shown in the red and blue boxes in the figure (the left side is the acquisition channel, and the right side is the nanosecond time stamp of the image frame), the synchronization error between the three cameras.Approx. 15 microseconds (µs)The results are consistent with the previous test. Among them, Channel 4 is the bypass data channel of Channel 0, as shown in the green box in the figure (the left side is the capture channel, and the right side is the nanosecond time stamp of the image frame). Time Error between Bypass Image and Original ImageApprox. 2 microseconds (µs)It shows that proFRAME maintains high stability and very low latency in both simultaneous transmission and bypass capture.

The proFRAME card triggers the three cameras to synchronize to start exposure and acquire image data, as shown in the red and blue boxes in the figure (the left side is the acquisition channel, and the right side is the nanosecond time stamp of the image frame), the synchronization error between the three cameras.Approx. 15 microseconds (µs)The results are consistent with the previous test. Among them, Channel 4 is the bypass data channel of Channel 0, as shown in the green box in the figure (the left side is the capture channel, and the right side is the nanosecond time stamp of the image frame). Time Error between Bypass Image and Original ImageApprox. 2 microseconds (µs)It shows that proFRAME maintains high stability and very low latency in both simultaneous transmission and bypass capture.

IV. CONCLUSION

Today, as intelligent driving and autonomous driving systems continue to evolve, theHigh precision time synchronizationIt has become a key foundation for multi-phase machine sensing systems in vehicles.Honghong and Solectrix from Germany to create the proFRAME Modular Image Acquisition and Injection BoardsWith a flexible architecture and five microsecond synchronization schemes, it helps R&D teams to easily synchronize multi-phase machines and multi-sensors.

Whether it's in-vehicle image fusion, ADAS perception testing, or ECU/HiL platform validation, proFRAME supports the R&D process with stable and repeatable synchronization performance, ensuring that every image is accurate.With its powerful scalability and cross-platform compatibility, proFRAME is becoming theSmart Driving is one of the mostOne of the most representative time synchronization solutions。

Want to make your ADAS and multi-sensor systems more efficient?

Want to make your ADAS and multi-sensor systems more efficient?

Acer proFRAME Modular Image Acquisition and Injection BoardsProvides scalable synchronization solutions to assist R&D teams in realizing microsecond timing and real-time data verification of multiphase machines, enhancing test efficiency and system stability.