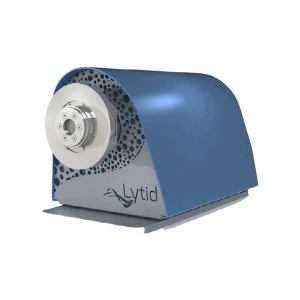

NIT I3MS Infrared Imaging Surveillance System

High-speed infrared imaging monitoring system for industrial process quality assurance

:: In-line infrared imaging surveillance system for industrial process monitoring

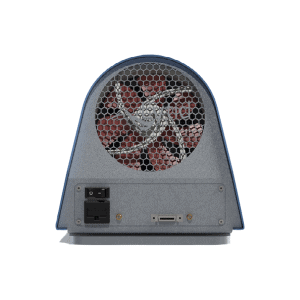

● Continuous monitoring and measurement of melt pool and HAZ geometry

● Ensure quality control

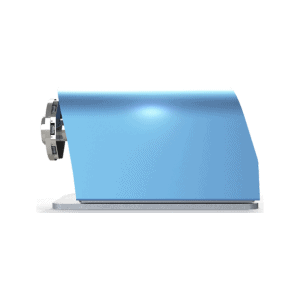

● Allow coaxial integration and off-axis operation.

● Stand-alone operation

● Level 2 alarm configuration, PC data logging

:: Main applications: laser welding, LMD, cladding, WAAM, etc.