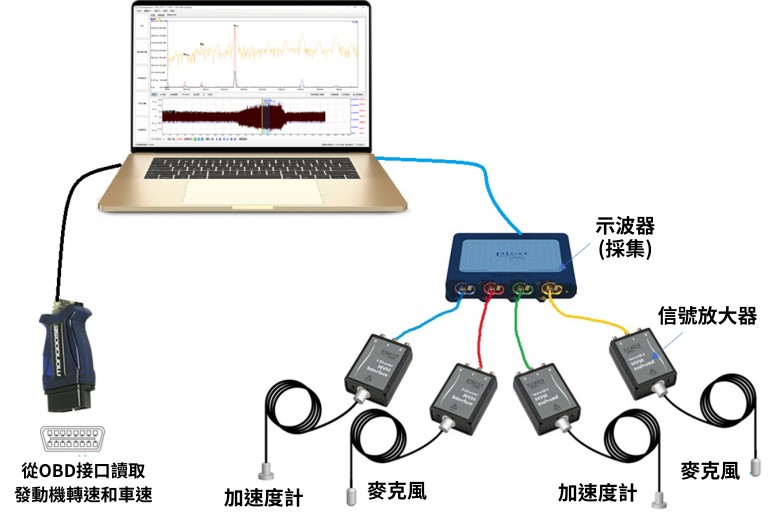

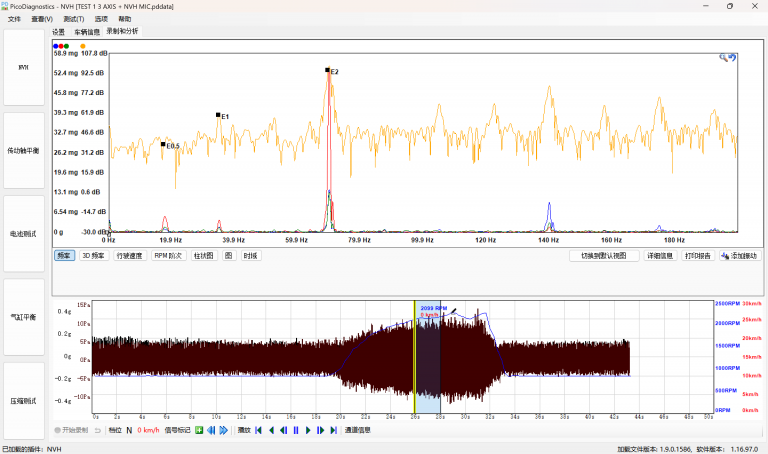

Vibration and noise (NVH) diagnostic program

It is a major challenge for maintenance technicians to reproduce and locate the faults of occasional noises (e.g. squeaks when passing over bumpy road surfaces) and continuous/periodic noises at a particular speed/revving speed during the driving process of a vehicle. The traditional test method is to use a chassis stethoscope, while the vehicle is running on the road, the technician operates the stethoscope to determine and analyze the faults; with this test method, the data is not visualized, cannot be saved and replayed, and analyzing the faults in a speeding vehicle also increases the safety risk.