introductory

In the new energy lithium industry, Optical Coherence Tomography (OCT) has become a key tool to improve quality inspection.Whether it is lithium battery plates, battery electrodes, or electrodes of hydrogen battery film, OCT technology realizes high-precision inspection of materials with micron resolution and millimeter depth, filling the gap of high-precision and low-cost inspection technology in the new energy field.

With the growing global demand for sustainable energy, the new energy industry is witnessing rapid technological innovation and market expansion.As a high-resolution optical imaging technology based on infrared interferometry, OCT has demonstrated significant advantages in the new energy field, and its application value is gradually being explored.

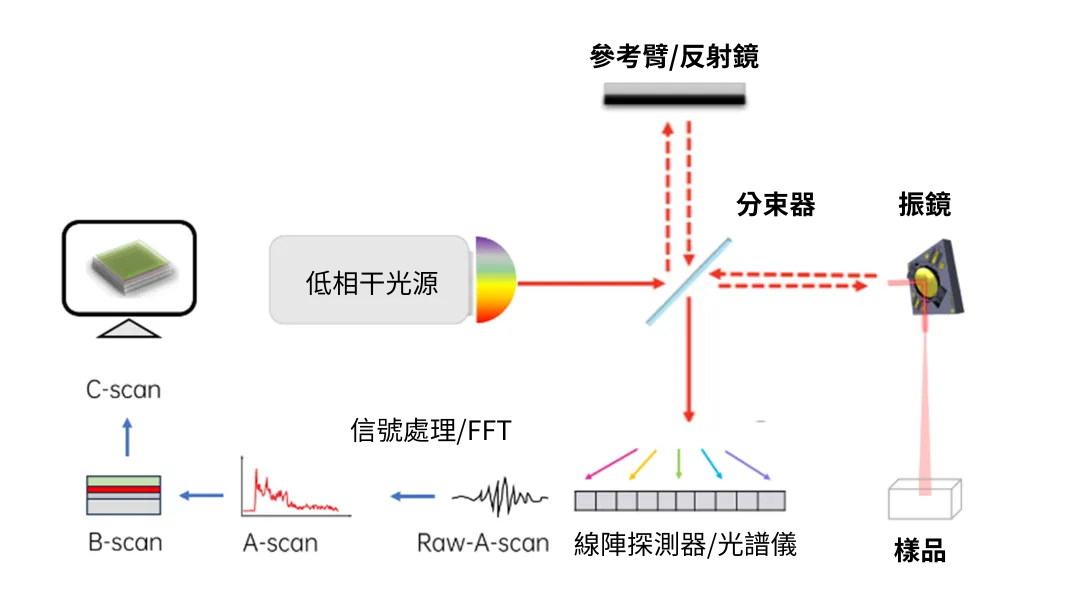

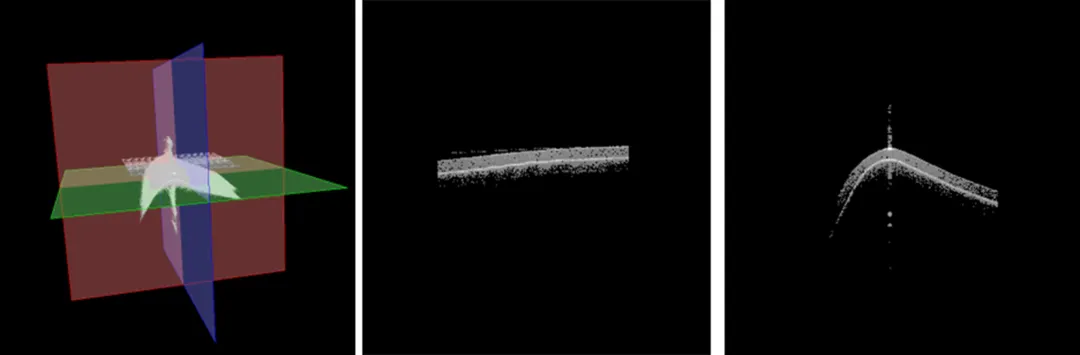

Figure 1 OCT Imaging Technology

The core of OCT technology lies in its micron-level imaging resolution and millimeter-level imaging depth.This gives it unmatched accuracy in material analysis, thickness measurement, defect detection, and surface topography evaluation.

Figure 2 Principle of OCT Technology

Application Scenarios

In the new energy industry, there is a growing demand for high-precision testing technologies, whether for the production and packaging of lithium-ion battery wafers, the manufacturing and quality control of photovoltaic solar panels, or the performance evaluation of hydrogen fuel cell membrane electrodes.Traditional visual inspection methods have played a role, but as process innovations continue to advance, inspection needs are becoming more diverse and refined.OCT technology is an important complement to traditional inspection methods due to its superior performance.

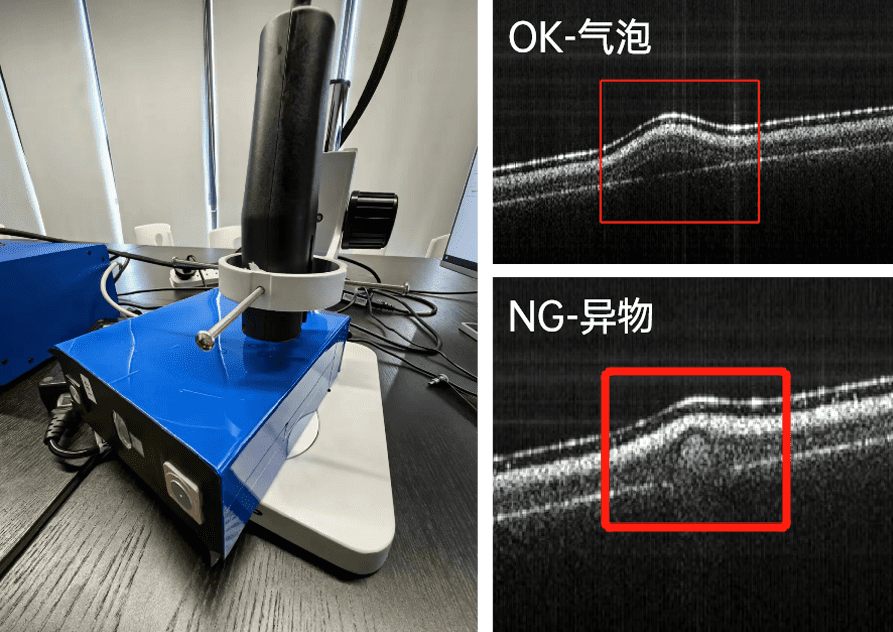

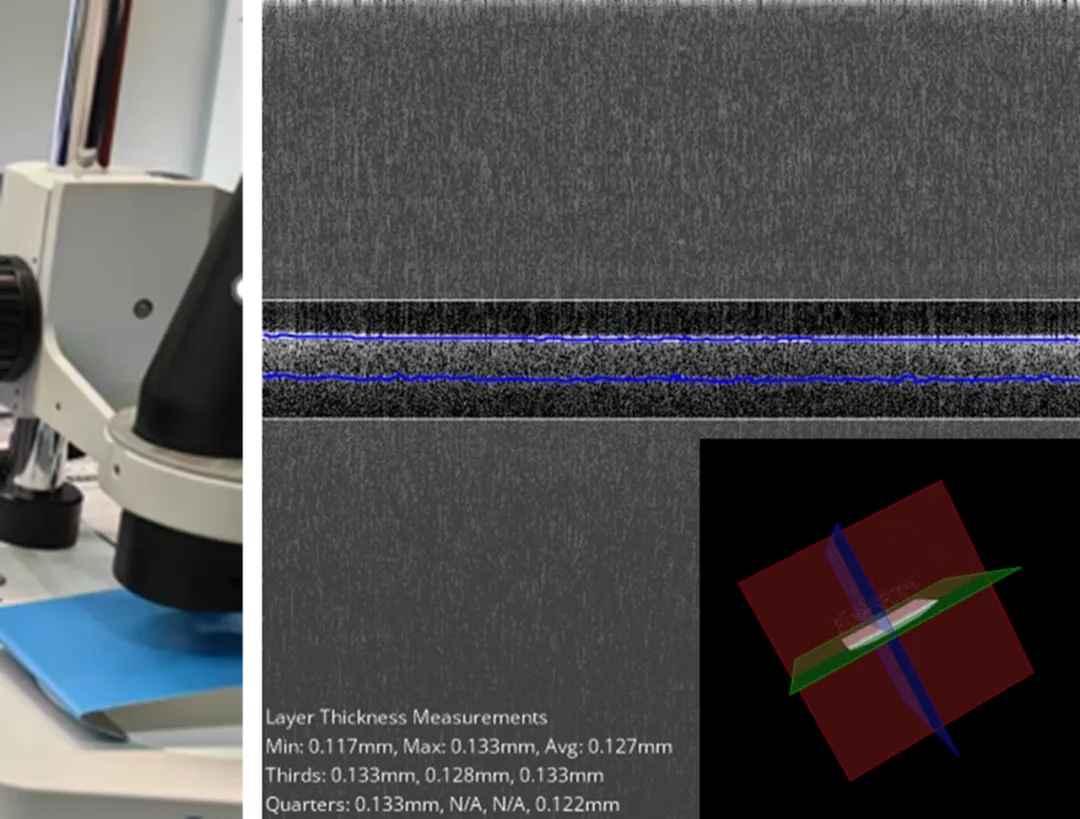

1. Quality testing of the outer packaging film for square shell batteries

Lithium-ion power batteries are categorized into square-case, cylindrical, and flexible pack batteries based on their packaging structure, with square-case batteries having the highest market share due to their cost efficiency and stability.Conventional appearance inspection equipment can recognize bumps, warps, tears and scratches, but cannot accurately detect internal defects in the film.For example, it is difficult to distinguish between air bubbles and foreign objects inside a bump, which is easily solved by OCT technology with contact-free, high-frame-rate, real-time visualization of cross-sectional imaging.

Fig. 3 Quality inspection of the outer packaging film of square shell batteries

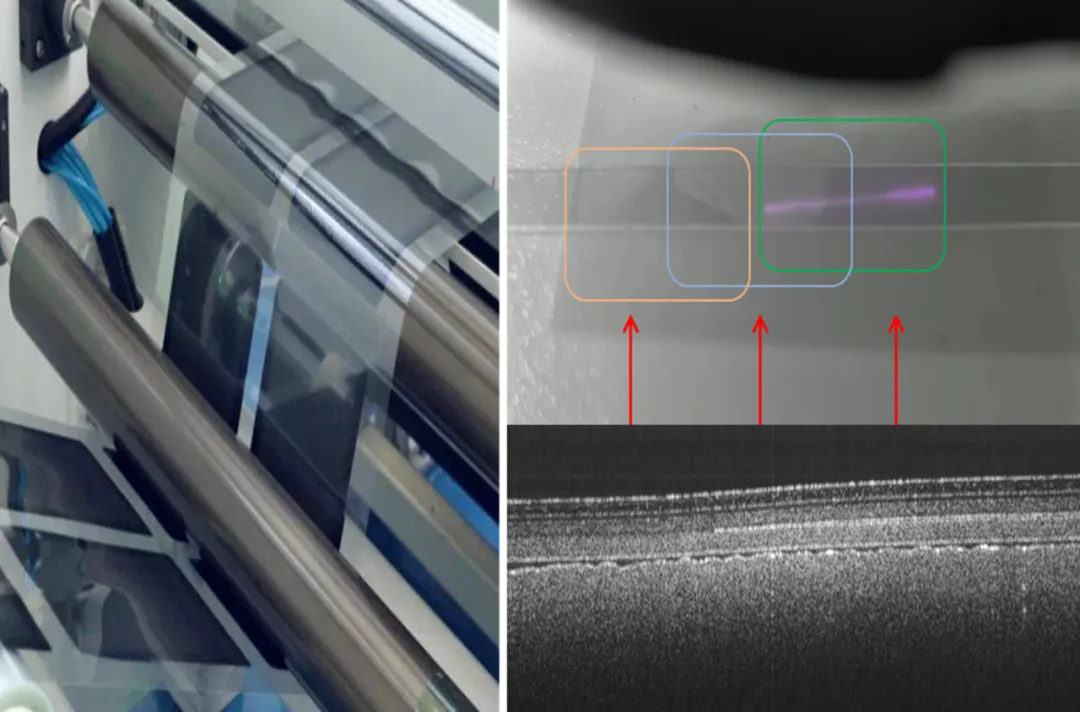

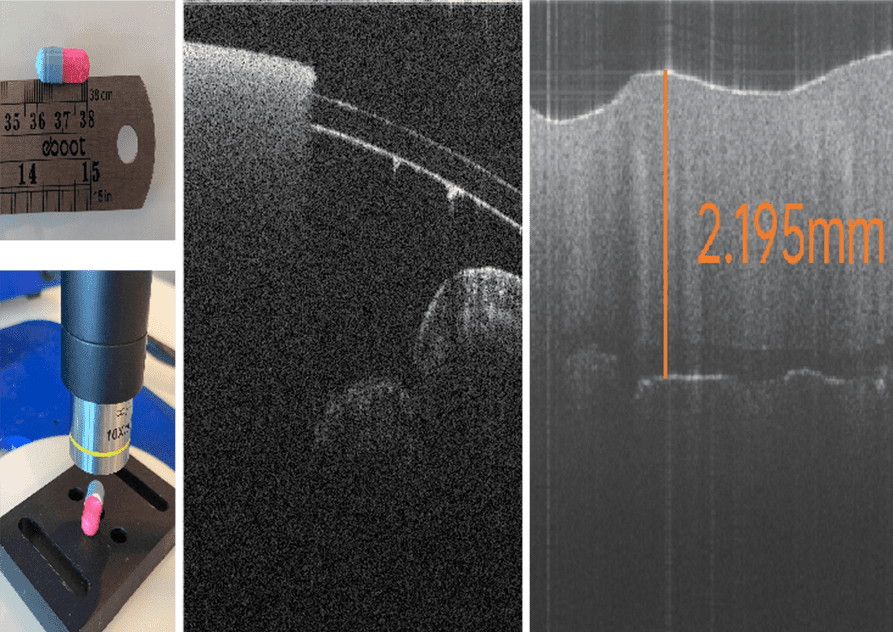

2. Battery Film Thickness Measurement

Based on the principle of interferometric measurement, the OCT is capable of micron-level thickness measurements (3-6mm) of materials such as packaging films, polarized tapes, etc., as well as differentiating multi-layer structural materials. With galvanometer technology, OCT can realize real-time scanning and 3D imaging of wide-area planes of 10mm or more, which is suitable for precise inspection of thickness consistency, surface flatness and internal flatness.

Fig. 4 Battery Film Thickness Measurement

3. Hydrogen Fuel Cell Membrane Electrode Inspection

The Membrane Electrode Assembly (MEA) is the core component of a hydrogen fuel cell and has a direct impact on the efficiency and life of the cell.OCT technology accurately detects catalyst layer adhesion, proton exchange film thickness, and bonding status.It helps ensure the reliability and performance stability of membrane electrodes for hydrogen fuel cells.

Figure 5 Hydrogen Fuel Cell Membrane Electrode Inspection

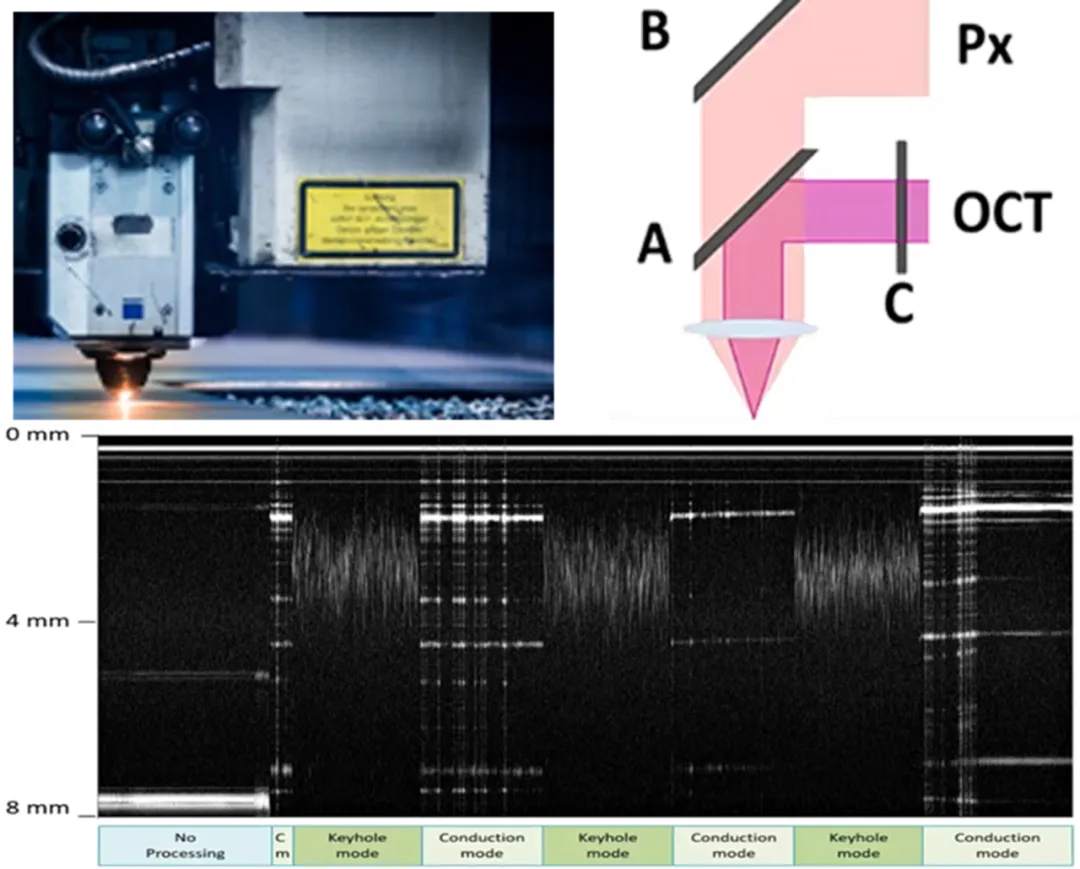

4. Online monitoring of laser welding depth of fusion in the battery industry

Laser welding is widely used in battery top cover welding and PACK welding. Compared with the indirect evaluation of conventional spectral signals, theOCT realizes real-time monitoring of the weld depth by coaxial integration of the measurement beam with the process laser beam.The quality of the weld is greatly improved.

Figure 6 Online Monitoring of Laser Welding Depth in Battery Industry

Program Advantage

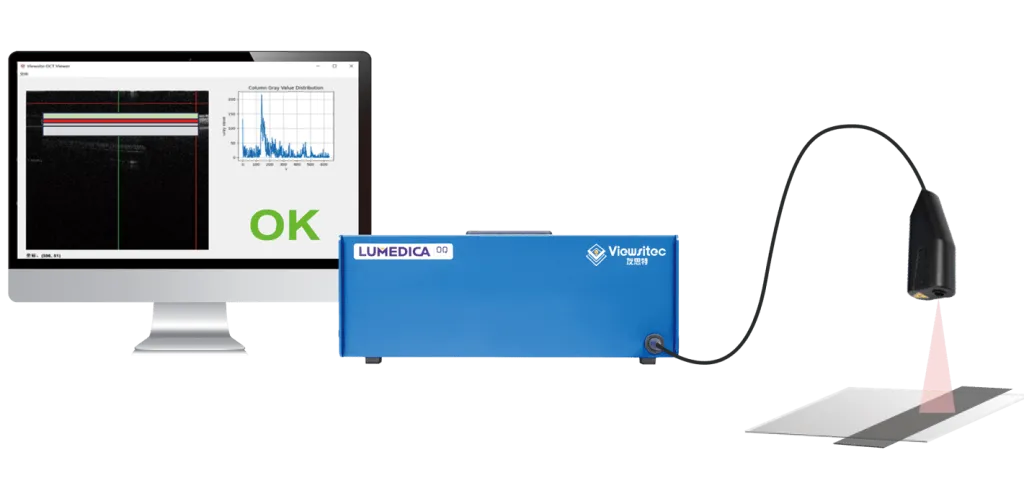

1. Ease of integration

The OQ Labscope series is a compact and lightweight system with a fiber optic connection that can be extended up to 3m in length.It also supports industrial-grade cable protection sleeve design for easy integration with other automation mechanisms.

Fig. 7 Schematic diagram of fiber optic probe operation of Honghong OCT system

2. Immediate multisection imaging

The OQ Labscope series features flexible scanning modes, including cross scan, ring scan, long scan, etc., and supports customization of scanning rate, density and range.The B-scan frame rate is up to 50 fps to meet the needs of a wide range of applications.

Figure 8 Real-time Multi-Section Imaging

3. Low-cost organization

Traditional OCT equipment is expensive and usually used in the medical field. Honghong's patented technology realizes the low-cost design of light source and spectrometer, and combined with algorithmic compensation, significantly improves the imaging performance, expanding the application of OCT technology in the industrial market.

Figure 9: More Potential Industries for OCT Technology

Conclusion

OCT Optical Coherence Tomography (OCT) technology is leading the new energy lithium industry towards a higher quality testing future with its accuracy and versatility.Whether it's lithium batteries, hydrogen fuel cells, or other new energy materials, Hong Hong's OCT solutions provide superior performance and reliability. Please feel free to contact us to explore more applications of OCT technology.

Product Recommendation

OQ LabScope 3.0 Series OCT Imaging System

- High-resolution imaging for a wide range of materials

- Flexible scanning modes to meet different application requirements

- Compact and lightweight, easy to integrate into production lines

- Cost-effective for industrial applications

OcuScience iVivo VET-OCT Series OCT Imaging Systems

- Professional OCT imaging equipment with outstanding performance

- High-precision testing for medical and scientific applications

- Advanced software features provide rich analytical tools

- Reliable and durable for long term use