Honghong will provide you with any support you need!

Our professional Honghong team will be the first to respond and provide you with the best service to solve all your problems.

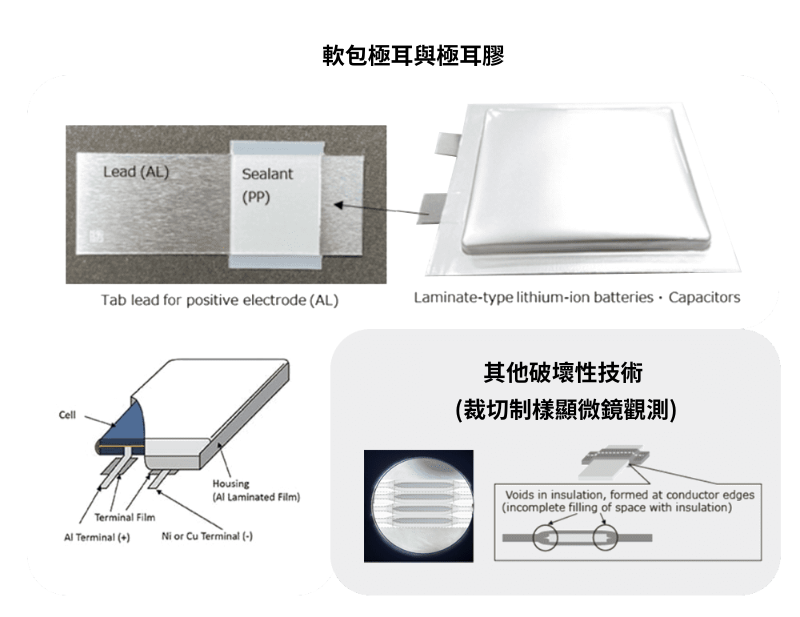

Honghong's OCT Solution for Flexible Packaged Battery Ear Gel & Film

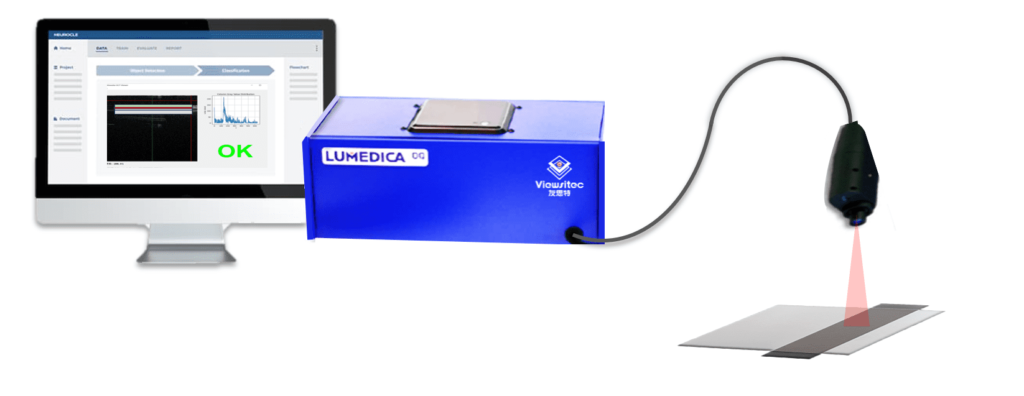

Based on OCT optical coherence tomography (OCT), the rapid cross-section image inspection/discrimination/measurement all-in-one solution, intelligent inspection in one step!

One-stop integrated solution for 2D/3D non-destructive analysis of internal multi-layer materials with real-time response to fit conditions.

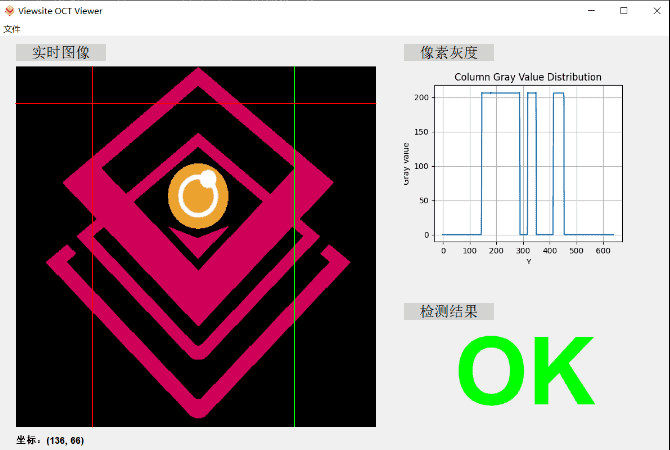

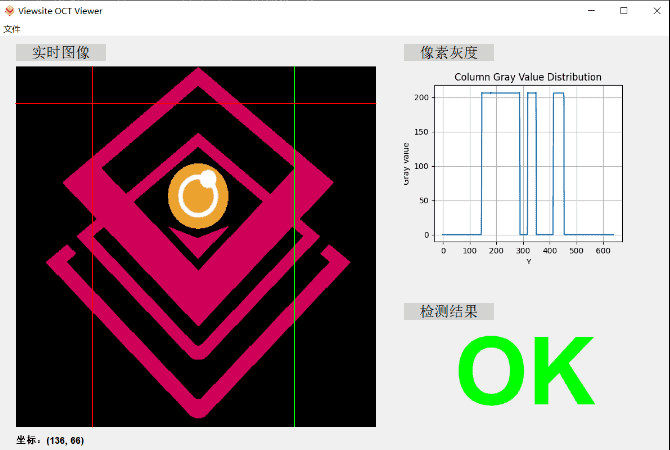

Self-developed technology platform automatically and quickly provides data processing results, improving inspection quality and efficiency simultaneously.

Surface contour scanning and fine measurement of impenetrable materials, with significant advantages in defect identification and measurement applications.

Automotive New Energy Battery Industry Needs to Test Film Lamination Quality to Ensure Insulation Performance

As the market for new energy electric vehicles continues to expand, the demand for high-performance, lightweight, and durable battery materials is also increasing, including tapes and film materials used in all stages of the battery packaging process.

For batteries operating under relatively high temperatures and conductive environments, the project places higher demands on the high performance and high temperature stability of the tape film material as well as the insulation properties of some of the connecting tapes.

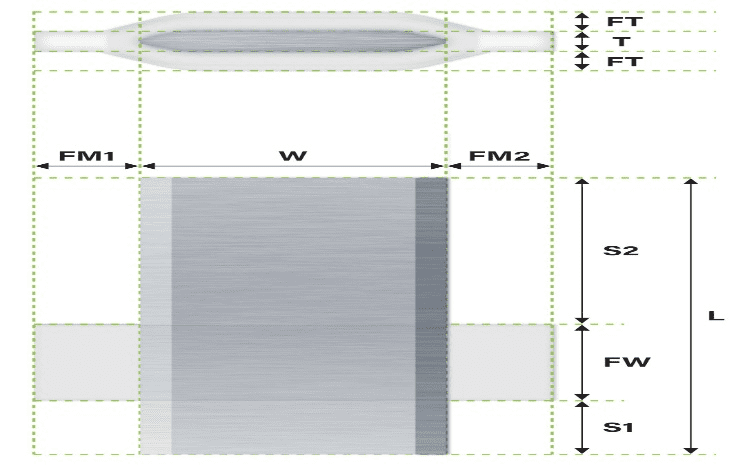

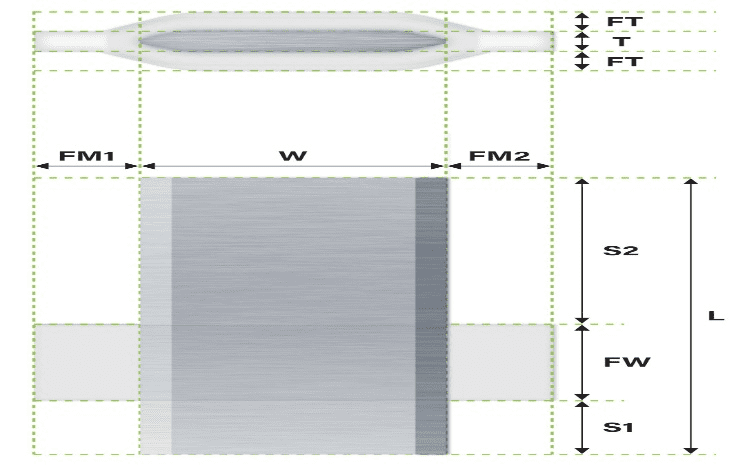

For the flexible pack batteries that use a lot of film and tape, the quality requirements of the electrode connection area are even higher, and the electrode tape often consists of 3-5 layers of material, so how to detect the adhesion of multi-layer tape and internal information is a difficult problem.

Based on advanced OCT optical coherence tomography (OCT) scanning equipment and self-developed image analysis software, Honghong provides an integrated solution for cross-section image inspection, discrimination and measurement.

The solution can not only perform multi-layer cutting, 2D inspection, 3D inspection, etc., but also analyze the material and thickness information of each layer and respond to the lamination situation in real time.

Honghong's self-developed non-destructive inspection method of A-scan image analysis assists in inspection, greatly improving the sensitivity, accuracy and efficiency of the system, thus ensuring product quality, reducing production costs, and improving the reliability and competitiveness of industrial production.

Depending on your project requirements, Honghong can also customize a one-stop OCT solution for a wider range of products, please contact us if you need!

Non-destructive detection based on infrared optical signals

Compact, customized solutions can be integrated according to project needs

Surface contouring and fine measurement of multi-layer materials.

Up to 80kHz-A scanning speed for real-time 3D rendering.

Self-researching analytics platform, data results at a glance

Vertical and lateral spatial resolution in the micron range

Data insights at your fingertips - MAXTRONIC's self-developed A-scan image analysis tool automatically and quickly generates image processing results to give you a full picture of your data. The platform provides multi-dimensional real-time measurement, intuitively assists in rapid identification and classification, and supports 2D/3D multi-dimensional customized analyses to trace the data network, statistical trends, and enhance the value of data applications.

Intelligently and accurately locating and resolving possible defects in production

Compact, customized solutions can be integrated according to project needs

Contribute to the protection of the environment by effectively reducing the generation of waste products.

Intelligent platform greatly reduces labor costs and improves production efficiency.

Honghong's innovative OCT lithium electrode tape inspection technology provides reliable support for the identification and measurement of Pole New Energy's small, medium, and large size electrode tape products, which not only helps our partners to easily distinguish OK from NG products, but also plays an important role in the field inspection of international production lines. Together with Honghong, you will have access to leading-edge technology that will improve both product quality and efficiency.

Our professional Honghong team will be the first to respond and provide you with the best service to solve all your problems.

Address: 3F, No. 99, Jingye 1st Road, Zhongshan District, Taipei City, Taiwan (Da Wan Technology Center Building)

3rd Floor., Dawan Technology Center Building, No. 99 Jingye 1st Road, Zhongshan District, Taipei City, Taiwan

©2025.hongtronics. All Rights Reserved.