Hong Kong Diagnostics | 2015 Maserati Vibration Noise Analysis of GT "Buzzing" at 80 km/h

Failure phenomenon

A 2015 Maserati GT with M139P engine and approximately 130,000 kilometers. Owner's comments: A "humming" sound occurs when the vehicle accelerates to about 80 km/h.Replaced 4 tires, but the noise problem still exists.

NVH Troubleshooting

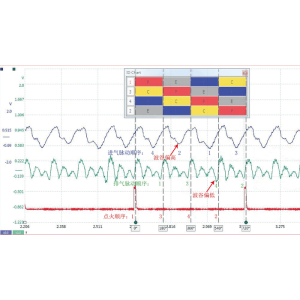

The technician uses the Acer Pico NVH diagnostic equipment to install the three-axis acceleration sensors on each of the three axes: Driver's side seat rails, microphone fixed to the inner compartment The following is a summary of the findings of the road test. Road tests were conducted and found: The noise is most noticeable at approx. 80 km/h and is accompanied by a slight acceleration. Fig. 1|NVH Waveform

NVH waveform analysis: The collected NVH waveform is shown in Figure 1. When the noise is generated, the microphone signal (yellow color) shows a clear spike with a frequency of about 586 Hz and a sound intensity of 54.9 dB, accompanied by an obvious vibration response. In addition, the frequency of the spike varies with vehicle speed: when the vehicle speed increases slightly, the spike moves to the right and the frequency increases; when the vehicle speed decreases, the spike moves to the left and the frequency decreases. Conclusion: 1. Detects clear 586 Hz aliasing peaks. 2. Sound pressure up to 54.9 dB 3. The characteristic of "stable tuning" of the echoes, which increases in tandem with the increase in vehicle speed. 4. Frequency and sound pattern are in accordance with typical mechanical resonance noise.

The technician further used the "Band Pass Filter" function (retaining 520-610 Hz) to convert the microphone's continuous signal into an audio file and played it back to confirm that the band sound matched the owner's description of the anomaly.

Fig. 2|Audio File Link ( Open WeChat and scan to listen )

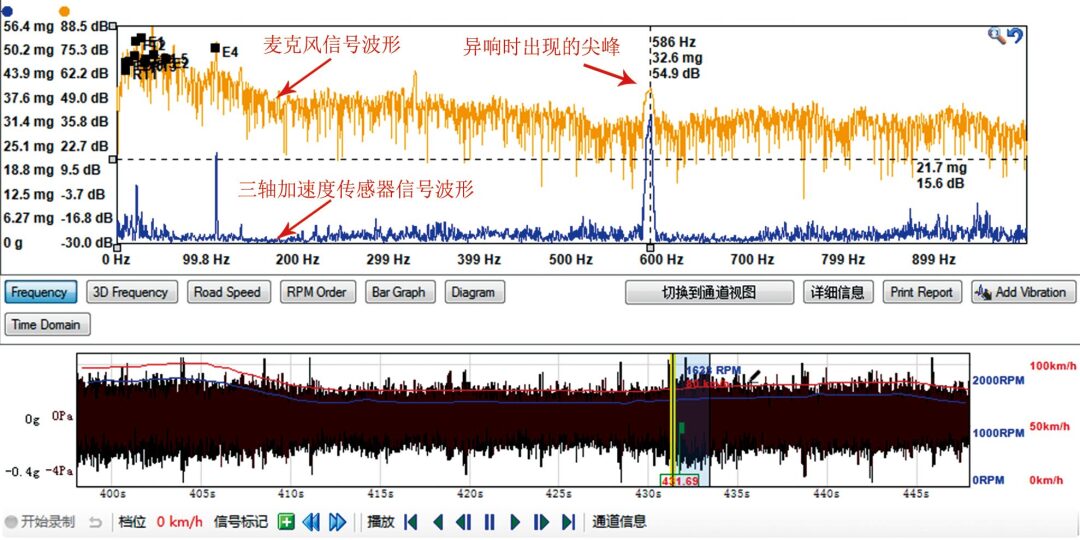

And then.Use the 3-axis accelerometer as a microphone.The following are some examples of sequential measurements: 1. Automatic transmission housing 2. Rear Differential Body 3. Drive shaft suspension bracket 4. Wheel bearing position

Fig. 3|NVH Waveforms on Rear Differential and Drive Axle Over-axle Bearing

The test results show that:The vibration signal is most pronounced at the rear differential position (Fig. 3).The frequency of the heterodyne was identical to that analyzed in the previous paragraph. Hence the inference:The source of the noise is the mechanical vibration and resonance noise generated by the rear differential.

fault resolution

changeRear Differential AssemblyAfter returning to the factory for road test, the "buzzing" noise completely disappeared. The "buzzing" sound disappeared completely and the problem was solved.

Fault Summary

Through the precise measurement and frequency analysis of the Pico NVH Diagnostic Tool, this case successfully quantified the seemingly complex noise problem and gradually pinpointed the real source of the noise. From road testing, frequency filtering, waveform comparison, to final confirmation of the rear differential abnormality, to actual replacement and elimination, the entire process demonstrates the efficiency and reliability of systemized NVH diagnosis in vehicle maintenance. For technicians, it is often not easy to determine the source of an abnormal sound with the naked ear; however, through scientific NVH tools, the "inaudible details" can be transformed into visualized data, which makes fault location faster and more convincing, and also effectively reduces the cost of misdisassembly and misjudgment. In the future, NVH diagnosis will continue to be an indispensable technology in the field of vehicle warranty, abnormal sound analysis and quality verification.