Case Overview

Honghong MSR165 Vibration Recorder

preamble

In the global rail transportation system, subway trains need to be continuously supplied with stable electricity during operation. Currently, the main power supply methods include contact rail (third rail) and contact grid. For example, the Tianjin Metro uses a contact rail system, while the Shanghai Metro mainly relies on contact grid power supply.

During train operation, the frequent contact between the contacts and the third rail provides the power needed for operation, but this process may also exert additional forces on the third rail, which may result in a shorter service life. ThereforeVibration monitoring of the track is essential to analyze the source of vibration and the cause of damage.。

Honghong MSR 165 Vibration Recorder

Background of cooperation

The Bangkok Metro Railway (MRT) has been in operation since 2004 and has built an important network of tracks covering the east, west, north and south of the city. on June 3, 2023, its newest line, the MRT Yellow Line, opened for trial operation, with a total length of 30.4 kilometers, 23 stations and interconnections with various systems such as the Blue Line, the Airport Express and the BTS Sukhumvit Line. The MRT Yellow Line is 30.4 kilometers long, with 23 stations and interoperability with the Blue Line, Airport Express and BTS Sukhumvit Line.

The Yellow Line was initially designed as an underground route, but was later converted to an elevated structure due to cost considerations. The third rail power supply solution was provided by one of the world's leading power equipment suppliers. In the implementation process, in order to further verify the stability of the system and the reliability of the rail structure, the customer introduced Honghong MSR165 vibration recorder, which is used to monitor the actual force condition of the power supply rail in the running process of the train.

Figure 2 Bangkok Metro Yellow Line Train and its Third Track

Practical application in the field

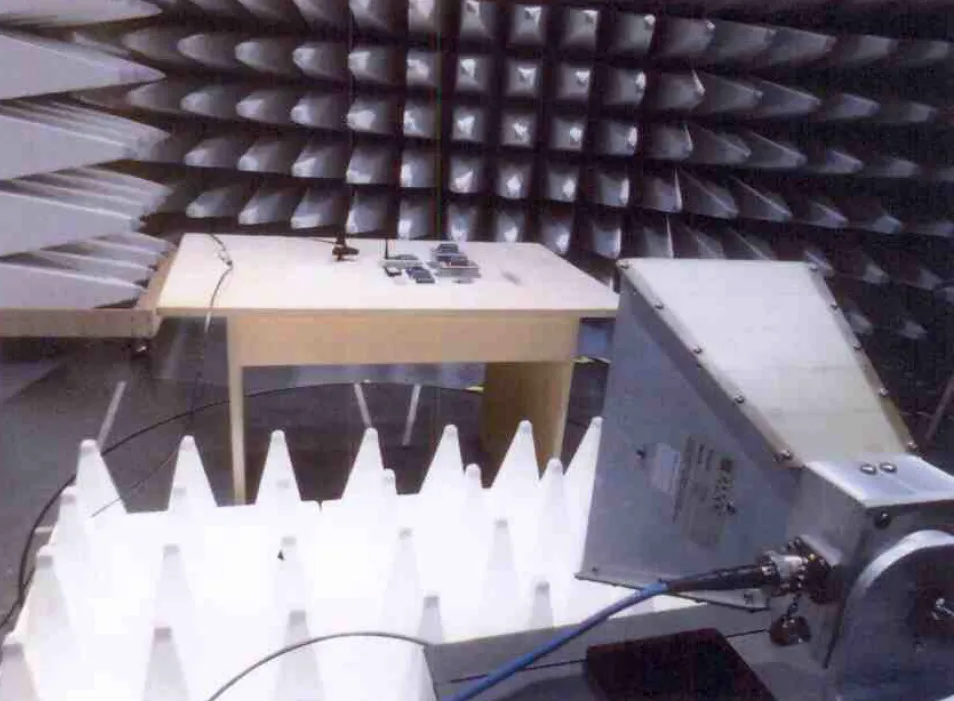

Considering that the third rail of the subway is a high-pressure conductor with strong electromagnetic interference and safety risks, the project team conducted several rounds of evaluation on the equipment selection and installation location.

even thoughThe MSR165 has passed stringent EMC electromagnetic compatibility tests and is capable of withstanding 8kV electromagnetic interference.However, to ensure personal and equipment safety, we finally used non-metallic insulated hardboard as the installation base. However, to ensure the safety of people and equipment, we finally used non-metallic insulated hardboard as the mounting substrate. We isolated the recorder from the metal rail and installed it in a safe area adjacent to the third rail by screwing. This method not only avoids direct contact of the recorder with the rail surface, but also facilitates subsequent disassembly and data reading.

Fig. 3 MSR165 recorder in EMC test and mounted on the third rail for vibration test.

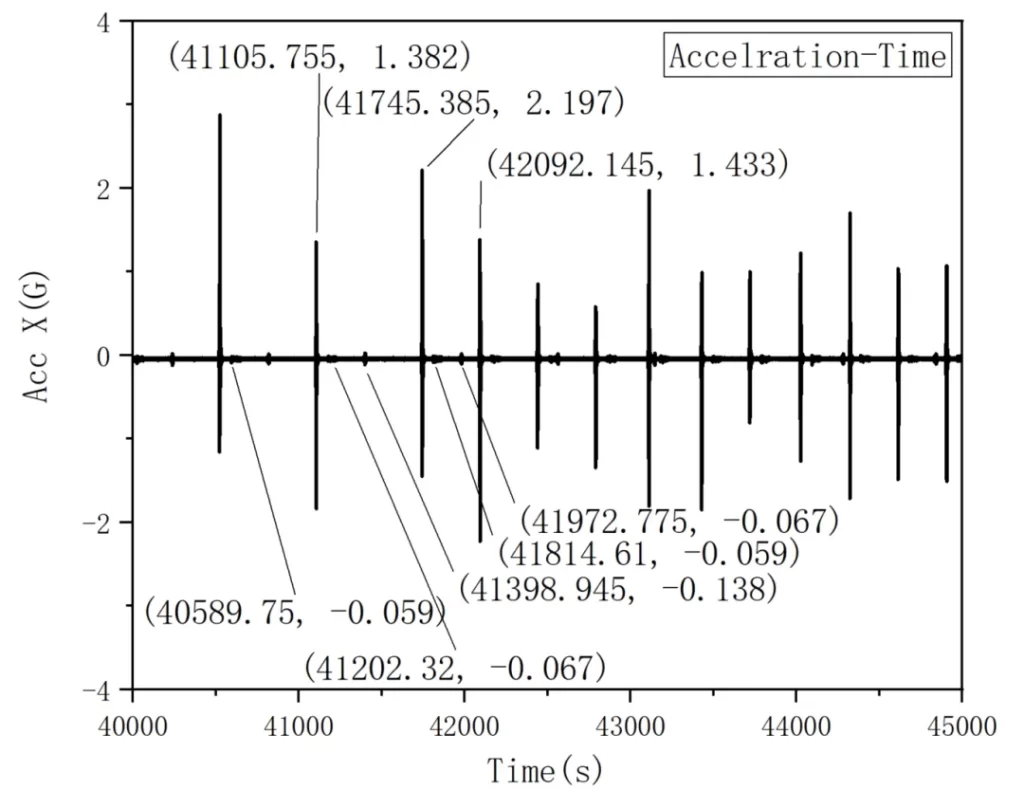

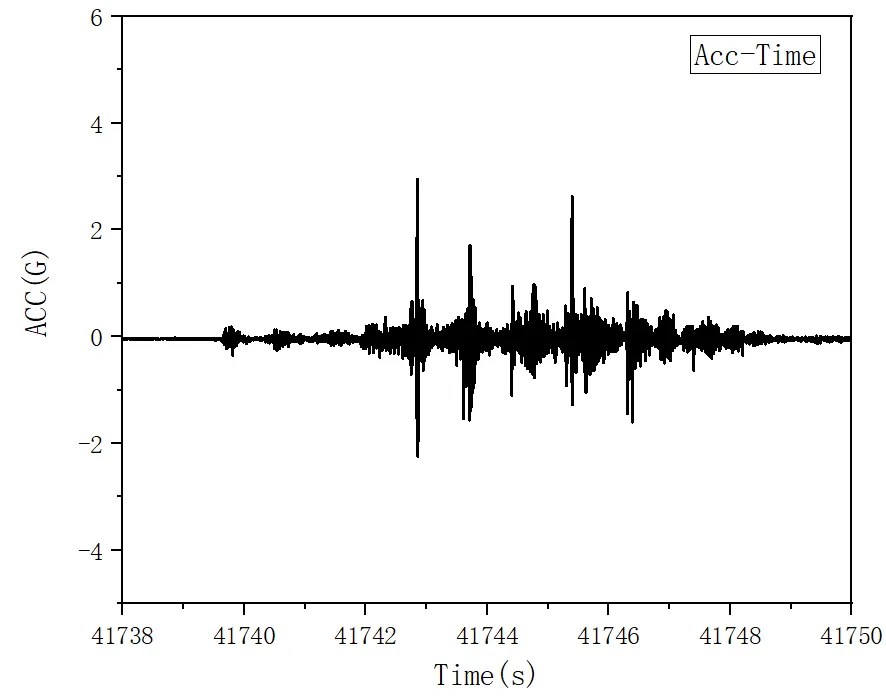

The sampling frequency of MSR165 is set to 200Hz, which can effectively capture vibration signals below 100Hz according to the Nyquist Sampling Theorem. It was found through the acceleration time-domain data (shown in Fig. 4) acquired by the recorder:

- Trains enter and exit the platform at 640-second intervals for the first half of the train's journey;

- The frequency of the second half of the run was accelerated and the interval shortened to 350 seconds;

- During operation, the third rail is subjected to a maximum shock acceleration of 3G and an average shock acceleration of about 1.5G;

- Zooming in on the individual vibrations reveals that the train's vibration on the third rail is a superposition of high and low frequencies, and that the duration of strong impacts exceeding 2G is relatively short.

Fig. 4 Time-domain signals of acceleration on the third rail

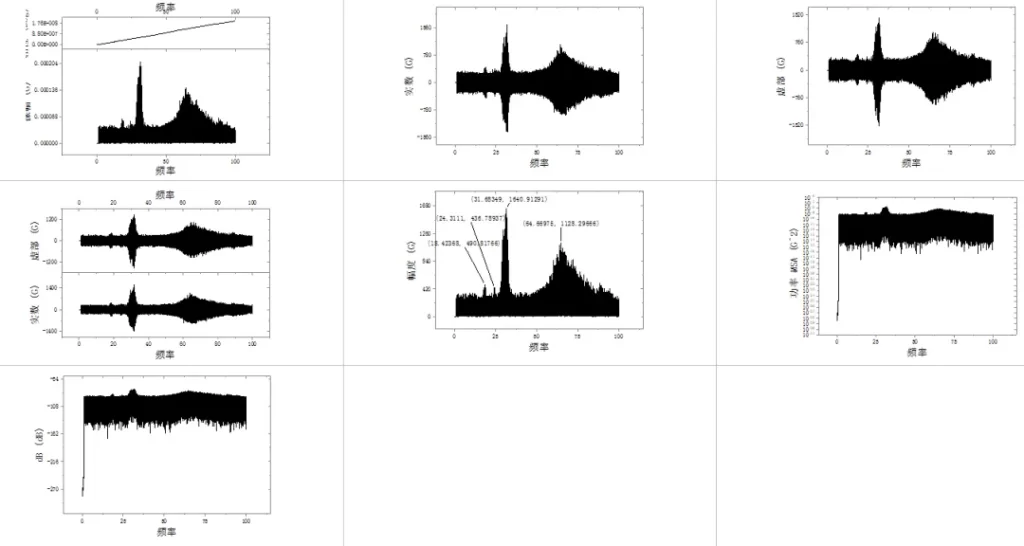

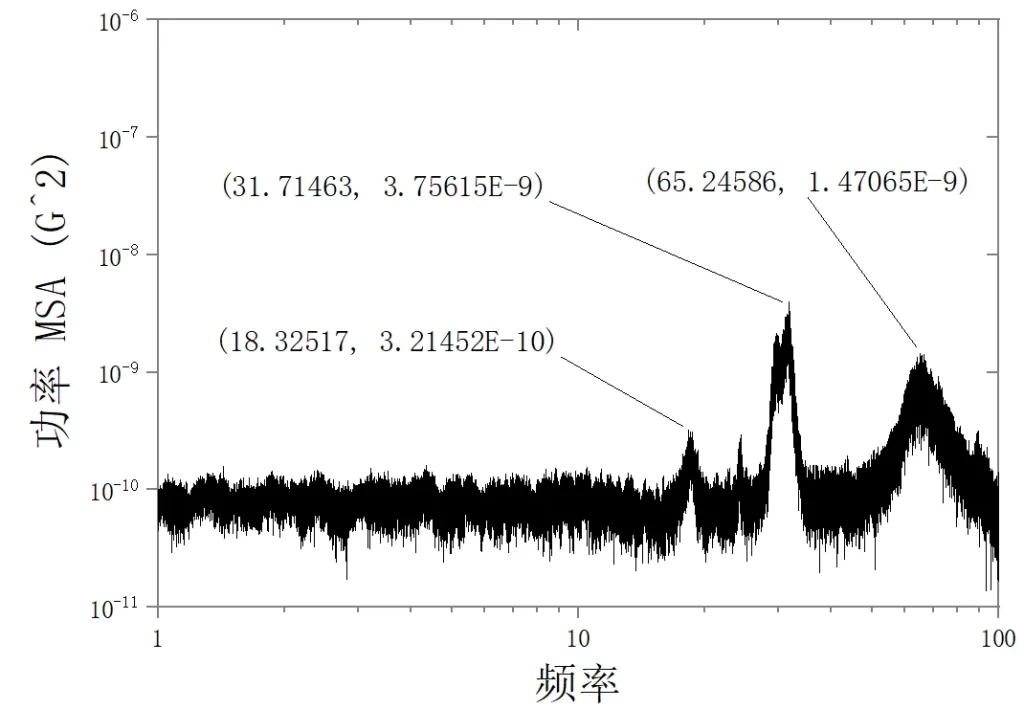

In order to further determine the source of the anomalous vibration in the third rail and the effect of the corresponding vibration source, the technician further used the Fourier transform technique to convert the time domain signal into the frequency domain signal. As shown in Fig. 5, the frequency domain signal of the acceleration on the third rail is obtained after Fourier transformation. The amplitude and power data are presented in Fig. 6. The analysis results show that the acceleration caused by the train on the third rail is mainly concentrated in 18.4Hz, 31.7Hz and 64.7Hz, and these three vibration frequencies are also the main sources of external impact energy on the third rail.。

Fig. 5 Frequency domain signals of acceleration on the third rail

Fig. 6 Amplitude and power of the signal varying with the vibration frequency.

Case Summaries

Bangkok Metro Group SuccessfulThe MSR165 Vibration Recorder was used to monitor abnormal vibrations and shocks on the third rail (power supply rail) during train operation.In addition, a qualitative analysis of the vibration sources and a quantitative calculation of the vibration intensity were carried out, which provided important data support for the subsequent optimization of the power supply system.

MSR165 Vibration Recorder

- Flexible sampling frequencyThe recorder supports adjustable frequency settings from 1-1600Hz, which corresponds to the actual vibration signal acquisition up to 800Hz;

- Triaxial acceleration monitoring:Built-in 3-axis acceleration sensor can analyze the vibration status in three directions at the same time;

- High electromagnetic compatibilityEMC tested, the device can work stably under high electromagnetic interference environment.

Honghong Technology is committed to providing high-precision and reliable vibration and environmental monitoring solutions for logistics and transportation, rail transportation, power and energy, and industrial automation.The MSR series has been widely used in many infrastructure projects around the world. MSR series products have been widely used in many infrastructure projects around the world, helping customers realize leapfrog development from data sensing to deep insight.

For more product details or to get support for similar cases, please visit our official website or contact our technical consulting team.

Learn more about our products

MSR165 Shock Vibration Data Recorder

- High performance shock and vibration data logger

- Acceleration sensor measurement/storage rate: 1600/s every 12 hours (±15%)

- Measurement/storage rate: 25 Hz~1600 Hz

- Continuous data recording for vibration measurements

MSR 175 Plus Transportation Vibration Data Logger

- MSR175plus for Impact and Weatherization

- Recording months of important traffic data at a time

- Up to 1024 Mpts per channel

- Use GPS to track location-critical traffic events

- Simple operation and extensive evaluation options

If you are interested, you are welcome to follow us for more information about the article and contact us if you have any questions!