01 Failure phenomenon

A 2020 Toyota Levin with a 9NR engine has accumulated approximately 130,000 miles. Owner feedback.A number of fault lamps on the combination meter illuminate abnormally while drivingThe fault light will go out when the engine is turned off and restarted. When the engine is turned off and restarted, the malfunction light will go out. Afterbumpy roadProblems are particularly likely to arise when the Government has to take a step back from the Government's position in the market.

02 Troubleshooting

Figure 1: Fault Code Read Out

After repeated test drives on a bumpy road, the fault occurred again.The airbag malfunction light and the pre-collision system malfunction light on the combination meter are abnormally illuminated.This means that a fault code starting with the letter "U" is stored in several control modules. After testing with the Troubleshooter, it was found that fault codes beginning with the letter "U" were stored in several control modules, which means thatcommunication breakdown。

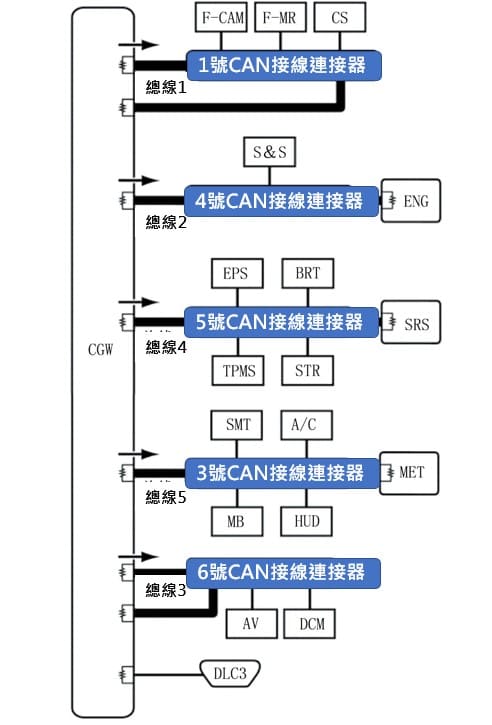

Figure 2: Communication Bus Inspection

Subsequently, a communication bus check was conducted and all control modules were able to communicate normally, which indicated that the fault wasepisodicAfter reviewing these fault codes, it was found that the main problem was related to the fault codes. Upon reviewing these fault codes, it was found that they were mainly related toBrake System Control Module, Airbag Control Module, Steering Angle Sensor and Traverse SensorThe components with which communication has been lost.

Figure 3: Communication bus topology of the faulty vehicle

From Fig. 3, it can be seen that all the control modules that lost communication are inCAN Bus No. 4Up.

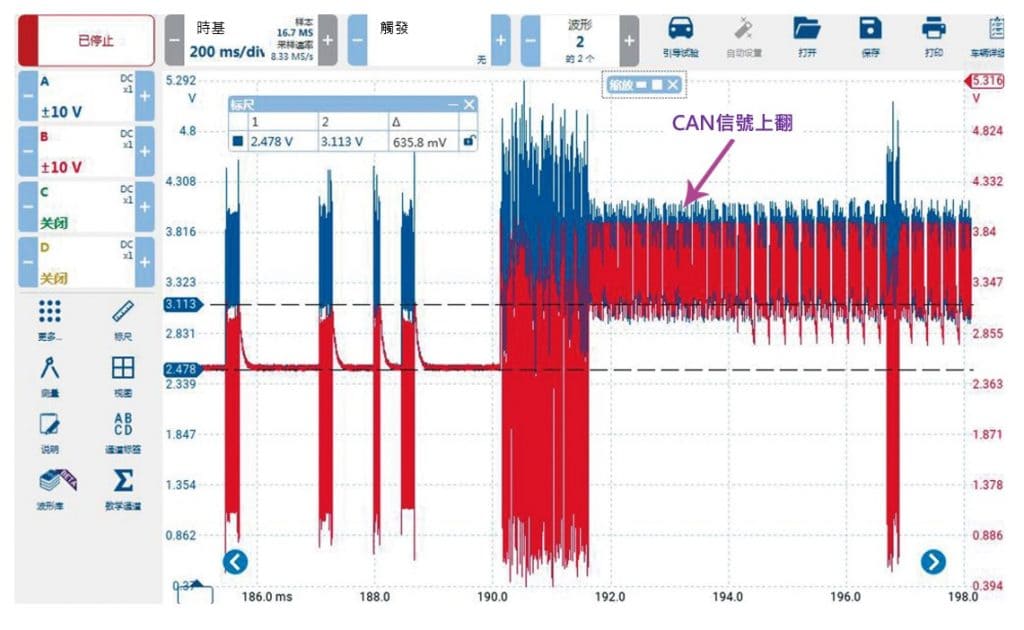

Figure 4: Waveforms on CAN bus #4

By measuring the waveforms on CAN bus #4 at the central gateway ECU, it was found thatThe CAN L signal will flip up and overlap with the CAN H signal during a fault.This is consistent with the waveform when the CAN L line is disconnected. This is consistent with the waveform when a break occurs on the CAN L line, and it is inferred that theThe CAN L wire on CAN bus No. 4 may have poor contact or occasional breakage.。

03 Troubleshooting

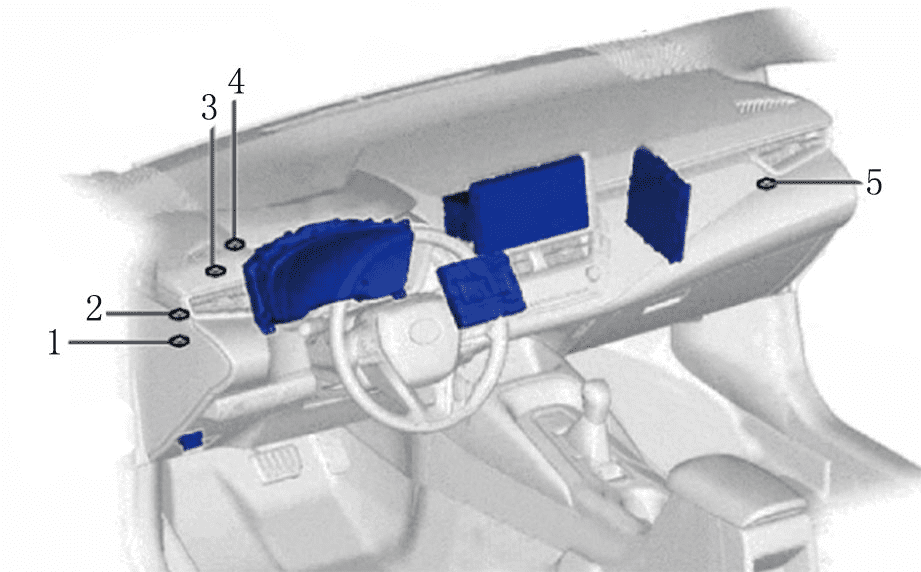

Figure 5: Location of each CAN connector

During further inspection of the #5 CAN wiring connector, it was found that the fault could be reproduced by gently tapping on the housing. Final ConfirmationLoose CAN connector #5 terminal 8 (CAN L terminal of the central gateway ECU connected to CAN connector #5).。

Figure 6: CAN Wiring Connector #5

After repairing terminal 8 of CAN connector No.5, after several road tests, the problem did not occur again and was successfully solved.

04 Conclusion

In this troubleshooting, we firstly based on theFault code locks out the CAN bus where the problem occursand captured with a Pico oscilloscopeCAN Signal Waveforms During Faults. By analyzing the waveforms, it was determined thatFault type is CAN L line breakIn the end, we found the specificTroubleshooting。