Honghong will provide you with any support you need!

Our professional Honghong team will be the first to respond and provide you with the best service to solve all your problems.

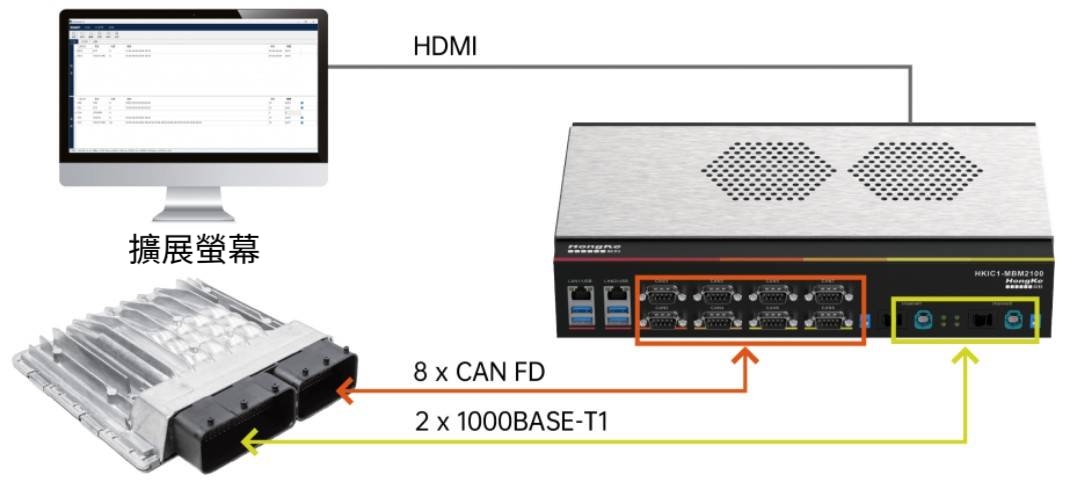

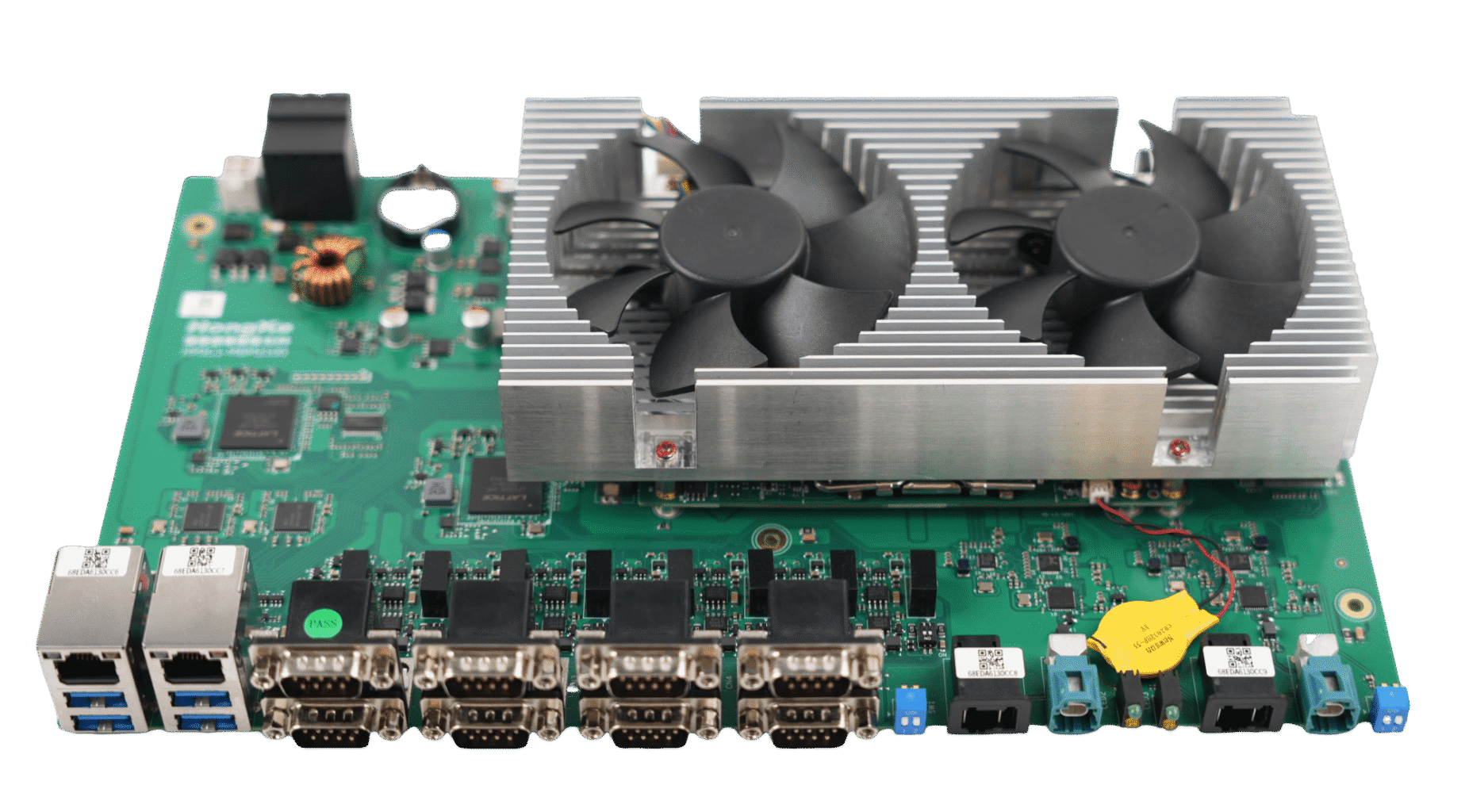

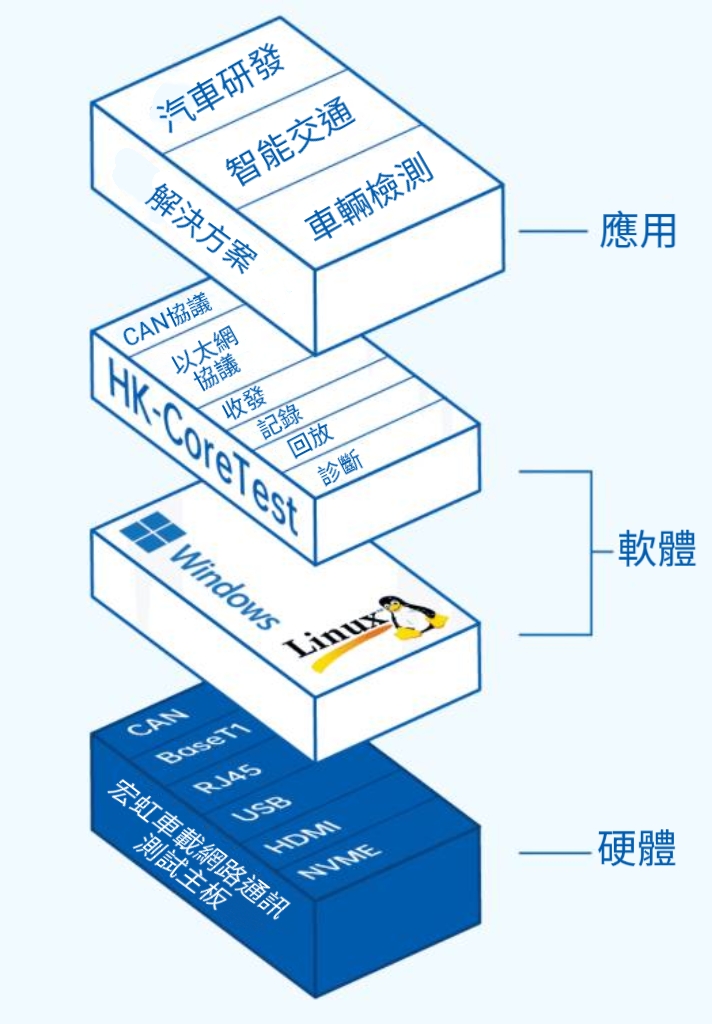

The Honghong Vehicle Network Communications Test Motherboard (HKIC 1 - MBM 2100) is a high-performance industrial computer motherboard designed for vehicle network communications, used to monitor, simulate, and analog CAN (FD) and T1 network packets, with powerful data processing and communication capabilities. It integrates 8-channel CAN/CANFD interface and 2-channel 1000 BASE-T1 interface, which is compatible with PCAN underlay driver, and can meet the test and data transmission requirements in complex vehicle network environment, and is widely used in automotive research and development, intelligent transportation, and vehicle detection.

Traditional test equipment often suffers from data loss and delay in multi-protocol scenarios.

Multi-device combinations lead to complex wiring harnesses

Large space occupation and synchronization difficulties

Software Mandatory Upgrade Subscription

Average annual maintenance cost exceeds $500,000

In a complex in-vehicle network environment, a single CAN protocol cannot satisfy the user's needs, and there is a need to introduce technical requirements such as Ethernet.Reduced Space and Simplified Harness Layout, MAXTRON's Lightweight In-vehicle Network Communication Test Motherboards(HKIC1-MBM21000) solves this problem. It adopts an integrated platform to verify data transmission accuracy, simulate fault conditions to verify ECU response and processing capability, and at the same time conducts data performance testing under high load conditions, which can record data and events during the testing process for subsequent analysis.

✓ Data Acquisition and Recording

Through the on-board Ethernet interface, the data from sensors such as radar and camera can be collected in a high-speed and stable way, which is convenient for real-time monitoring and recording.

✓ CAN / CAN FD communications

It receives signals from the ECU of the vehicle, such as speed and steering angle, and at the same time, it can also send vehicle status information to the CAN bus, realizing the synergy of work with various systems in the vehicle.

✓ Parts Detection and Diagnostics

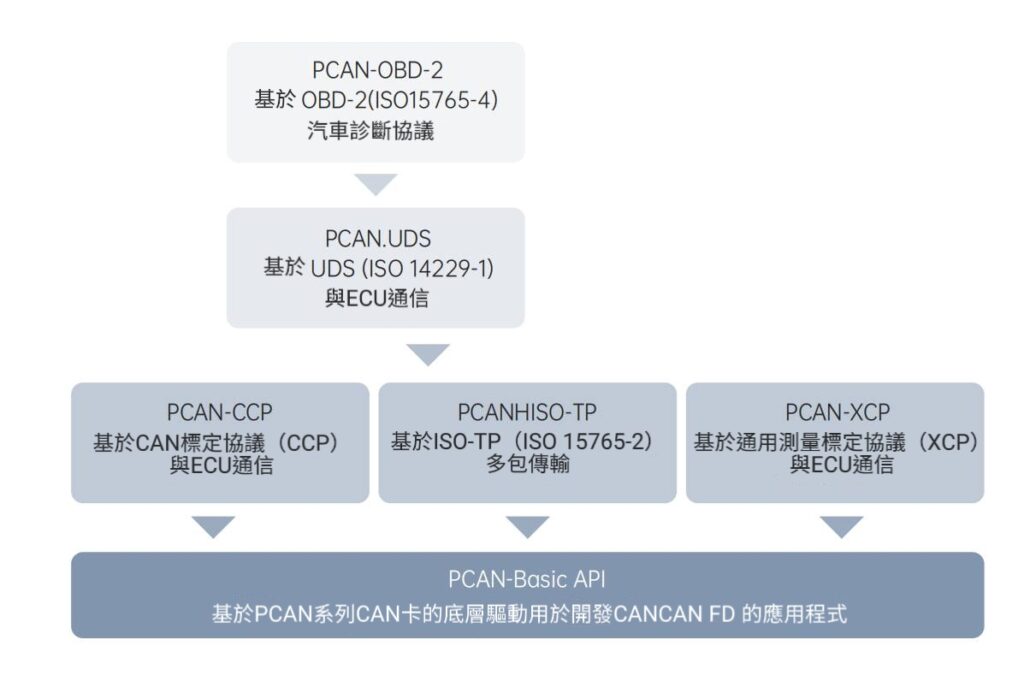

Diagnosis and calibration based on UDS, XCP protocols

✓ Port Expansion

USB3.0 interface and Ethernet port reserved for expansion of LIN bus, IO ports

Hong Kong Vehicle Network Communication Test Motherboard (HKIC1-MBM2100)

| Processor System | Intel-I7 12th generation (optional/upgradeable) |

| Memory | 32GB (optional/upgradeable) |

| Storage | 1T (optional/upgradeable) |

| Power Supply | 12-13.5V DC |

| Housing Dimension | (L) 300mm x (W) 180mm |

| Operating Temperature | 0ºC ~ 60ºC |

| IP Protection Class | IP 20 |

| Power | 70W |

Hong Kong Vehicle Network Communication Test Motherboard (HKIC1-MBM2100)

| External Interface (Rear I/O) | Communication I/O |

|---|---|

| 1 x HDMI (for display) | 8 x CAN (FD) (D-Sub, 9-pin) |

| 2 x GbE (RJ45, network connection) | 2 x 1000Base-T1 (MATEnet & H-MTD) |

| 4 x USB3.0 (5Gbps) |

Hong Kong Vehicle Network Communication Test Motherboard (HKIC1-MBM2100)

| CAN (FD) Transceiver | TJA1044GT |

| CAN (FD) Transceiver | FPGA Implementation |

| Base-T1 Transceiver | RTL8211FI-CG |

Hong Kong Vehicle Network Communication Test Motherboard (HKIC1-MBM2100)

| component | releases |

| Operating System (OS Support) | Windows 8/10/11 & Linux |

| HK-View | Version1.0 |

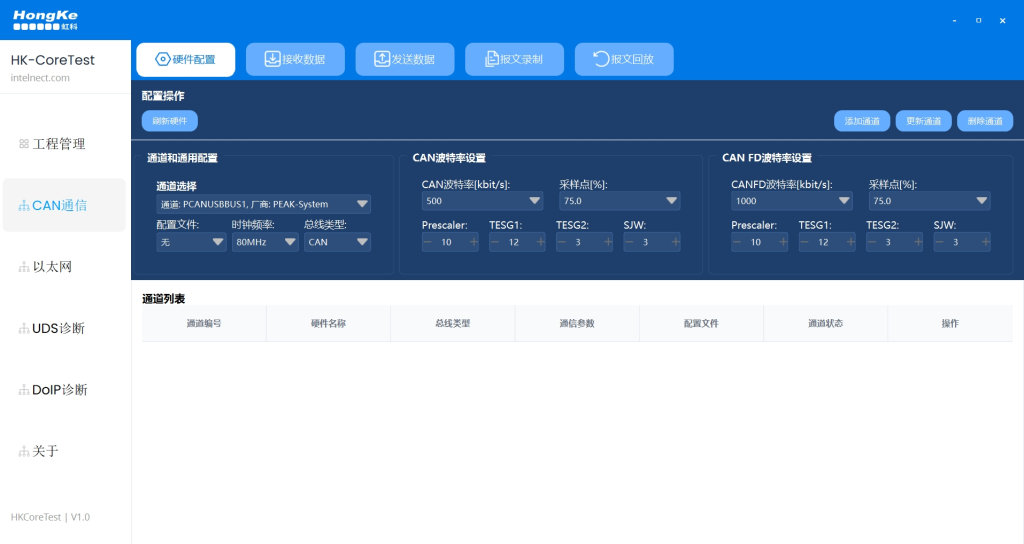

HK-CoreTest is a comprehensive tool for automotive electronic simulation and testing, which can connect, configure and control all Macrohon hardware (including: in-vehicle network communication test motherboards, PCAN-USB / PCIe series, and in-vehicle Ethernet tools) to realize automotive bus monitoring, simulation and diagnostic functions.

Simulated multi-ECU communication environment to test protocol compatibility and real-time performance

Simulate bus errors, network delays, and high load shocks to verify controller robustness.

Complete capture of test process reports to support traceability and consistency analysis

Our professional Honghong team will be the first to respond and provide you with the best service to solve all your problems.

Address: 3F, No. 99, Jingye 1st Road, Zhongshan District, Taipei City, Taiwan (Da Wan Technology Center Building)

3rd Floor., Dawan Technology Center Building, No. 99 Jingye 1st Road, Zhongshan District, Taipei City, Taiwan

©2025.hongtronics. All Rights Reserved.