preamble

Daimler AG, headquartered in Stuttgart, Germany, is the world's largest commercial vehicle manufacturer, the world's number one producer of luxury vehicles and the second largest producer of trucks. The company's four business units include Mercedez-Benz Cars, Mercedez-Benz Light Commercial Vehicles, Daimler Trucks and Daimler Financial Services.

I. Case background

An important part of Daimler's manufacturing process is the configuration and testing of the electronics used to operate a Mercedes-Benz. There are approximately 70-100 electronic control units (ECUs) in a Mercedes-Benz that operate functions such as brakes, lights, locks, entertainment systems, etc. Daimler created the Vehicle Diagnostic System (VDS) to coordinate the production of these control units for debugging and testing.The production of ECUs generates a large amount of data that needs to be sent to the IT department for further analysis and application.

The Vehicle Diagnostic System (VDS) is a critical part of the automotive manufacturing process, and a failure of more than 10 minutes can paralyze the manufacturing line. This is because the VDS performs some of the core functions in the manufacturing process of automotive electronic/electrical components, such as calibrating ECU-controlled sensors, quickly displaying new firmware, personalizing the vehicle's keys, and testing to ensure that each ECU is functioning correctly, as well as generating the test documentation required by the regulations of the country where the vehicle is destined for use.

II. Problems Ahead

Networks in factories are often not stable, which makes the connection of equipment in the factory unprotected. The VDS test equipment often needs to be moved around the factory floor, which can often result in network outages. However, as mentioned earlier, if the VDS fails for more than 10 minutes, it can cause the assembly line to stop, so it is important to minimize the impact of the network state on data transfer.

In summary, Dailmer will face the following challenges:

- Ensure that the VDS is not paralyzed;

- A reliable messaging platform is needed to realize the connection between factory data and the cloud;

III. Solutions

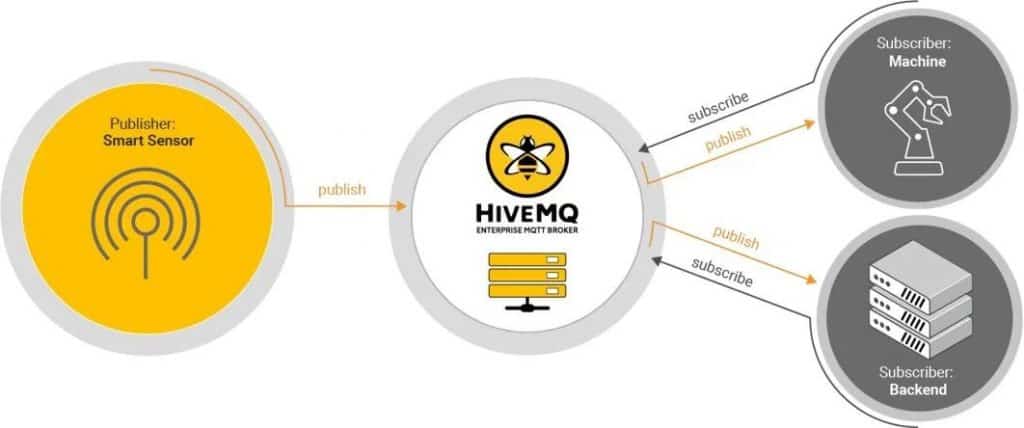

The strength of the HiveMQ solution lies in the simplicity and lightweight of the protocol itself, making it a fast, efficient and simple way to share information between factory floors and enterprise IT systems.

MQTT pub/sub ensures that test equipment will continue to function properly during disconnections and reconnections, and Daimler ultimately decided to use the MQTT protocol, adopting the HiveMQ Broker provided by HiveMQ as the core infrastructure service for its Vehicle Diagnostic System (VDS) to manage the flow of information between the test equipment and servers in the factory floor and the organization's IT systems.

Each instance of VDS consists of multiple test devices in a factory shop that are connected to a HiveMQ Broker located in the factory. On the server side, a series of microservices act as MQTT clients to the HiveMQ Broker. These microservices serve as the front-end to the various information databases and enterprise IT systems necessary to complete automotive VDS debugging and testing.

Daimler utilizes VDS at 24 of its plants worldwide, with approximately 10,000 test devices connected to VDS, sending 166 messages per second, or a total of nearly 470 million messages per month through the HiveMQ Broker for data transfer.

Why HiveMQ?

At the outset, Daimler considered AMQP and OPC UA, but found these protocols to be too complex and cumbersome for them. In addition, unlike HTTP, MQTT supports broadcasting messages, which is useful for VDSs that need to communicate with all their test devices. Daimler also considered solutions such as Mosquitto or RabbitMQ, but ultimately opted for the HiveMQ Broker because of its professional enterprise support and maintenance services.

“We wanted a solution that offered maintenance, testing and support. the HiveMQ team impressed us from the start. They responded quickly to our questions and requests and delivered a high quality product.

Jochen Vajda, Chief Architect, VDS

Now that the HiveMQ Broker provided by Symphony has been running in Daimler VDS for more than 4 years, Daimler is very satisfied with the reliability and stability of the HiveMQ platform. Marius Hertfelder, VDS Operations, said, ”We have been running VDS with HiveMQ for 4 years and the HiveMQ Broker has never failed. When we need to restart the HiveMQ Broker for some reason, the restart is quick and the downtime is very short. This is especially important because we can't stop the assembly line at the plant, and HiveMQ provides the stability and reliability we need for our system.”

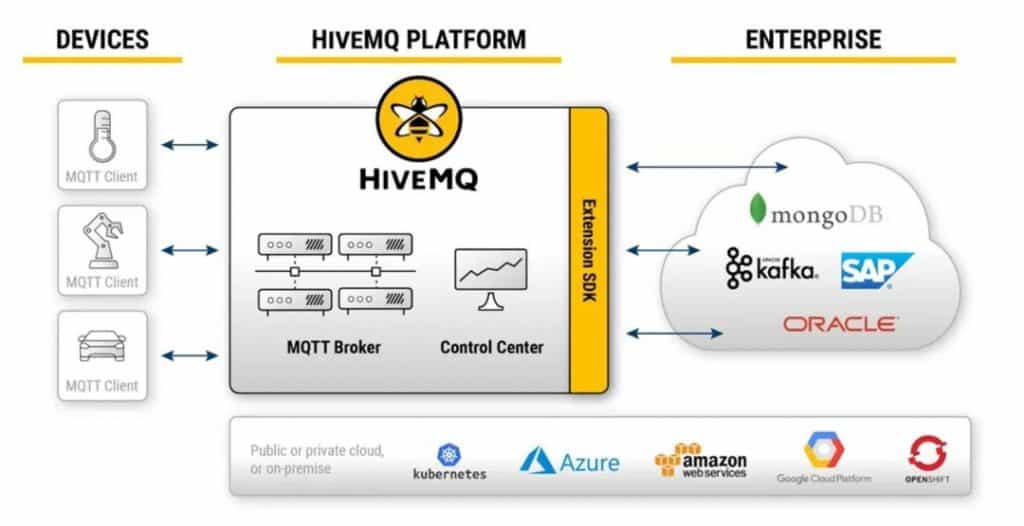

Introduction to HiveMQ

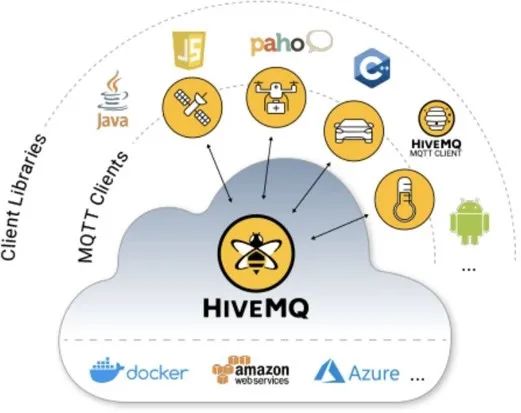

HiveMQ is a communication platform based on MQTT data transfer.Designed to deliver data quickly, efficiently and reliably to connected IoT devicesHiveMQ uses the MQTT protocol for real-time, bi-directional data push between devices and the enterprise platform.

HiveMQ was built to address some of the key technical challenges that organizations face when building new IoT applications, including:

- Building reliable and scalable business-critical Internet of Things applications

- Fast data delivery to meet end-user expectations for responsive IoT products

- Reduce operating costs through efficient utilization of hardware, network and cloud resources

- Integrate IoT data into existing enterprise systems

HiveMQ providesFree version、Professional Edition、Enterprise EditionMQTT Broker product with Kafka, Enterprise Security and MQTT Broker BridgeThree Enterprise Extension PacksHiveMQ also provides an efficient MQTT client and cloud platform to fulfill user needs in various aspects.