preamble

Client: Muller Martini AG, specialist for the printing and converting industry

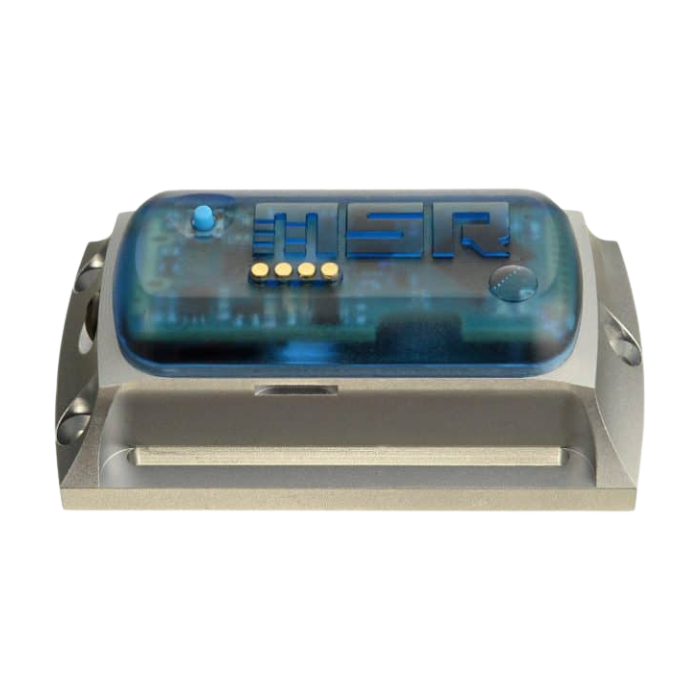

Application:HH-MSR165 Acceleration Data Recorder

Application Scenario: In the process of developing a new saddle bookbinding machine, a faulty sensor was found and the cause of the fault was determined using the HH-MSR165.

First, HH-MSR165 Accelerometer for Sensor Troubleshooting

01 Application Background

An edge sensor used in a new saddle-binding machine's three-blade trimmer failed during customer testing.Analysis revealed that the sensor element had suffered mechanical damage, possibly caused by vibration. Due to the dynamic motion of the machine, this problem can have a number of possible causes, so it is necessary to record the vibrations of the sensors to identify the source of the interference as accurately as possible, in order to draw the right conclusions and quickly verify the effectiveness of the measures taken.

After searching and comparing and communicating with the technical consultant, the global enterprise confirmed that the HH-MSR165 series micro data logger is the suitable measurement equipment.

02 Troubleshooting: HH-MSR165 Data Logger

The HH-MSR165 data logger is capable of performing 1600 measurements per second for up to five years. Its core component is a high-resolution 3-axis digital accelerometer, which is suitable for vibration measurements and shock monitoring, such as transportation monitoring, troubleshooting and load testing.Provides powerful data evaluation and graphical analysis functions with automatic report generation.

Figure 1: HH-MSR Micro Acceleration Data Recorder

The HH-MSR165 can monitor shocks up to ±15 g or ±200 g and record 32 measurements before an event occurs. It has a storage capacity of more than 2 million data points, enough to record more than 10,000 impacts, which can be expanded to 1 billion data points (10 million impacts) via microSD card. All data can be quickly transferred to a PC via USB or microSD card with PC setup and data analysis software and MSR ShockViewer software.

03 Measurement and test results

The DataCORDER was secured to the fault sensor of the new machine using double-sided tape, and during operation, the x-axis acceleration was as high as 218 g (Fig. 2); whereas, during the comparative measurements on the old machine, the acceleration was only 35 g (Fig. 3), which explains the damage to the sensor on the new machine.

Fig. 2: Acceleration measurement results of the new machine

Fig. 3. Acceleration measurement of the old machine

In addition, the acceleration waveforms of the old and new machines recorded in the field showed significant differences. By shutting down the subsystems, it was quickly determined thatThe huge acceleration is mainly caused by the pneumatic stops.A different length of hose was found between the valve and the stopper. After adjusting the hose to the same length as the old machine, the acceleration was restored to a reasonable level and the sensor manufacturer optimized for the higher acceleration, and the failure has not occurred since.

Fig. 4: Acceleration measurement waveform of the new machine

Fig. 5. Acceleration measurement waveform of the old machine

Case Summaries

The HH-MSR165 Data Logger is a key tool to ensure rapid fault location and resolution.This makes it possible to identify the cause of new machine sensor failures in a short period of time, significantly reducing the risk of production downtime.

Contact Macronix today for a complete HH-MSR impact vibration detection solution!Stay tuned with us for more technical updates!

Product Recommendation

MSR 175 Plus Transportation Vibration Data Logger

- For transportation monitoring and troubleshooting

- High-resolution sensor and long battery life

- Large data storage capacity and easy transfer

- Provides comprehensive vibration and shock data

MSR165 Shock Vibration Data Recorder

- Designed for shock and vibration monitoring

- 1600 measurements per second for accurate recording

- Storage capacity of over 2 million data points

- Fast data transfer via USB and microSD card