Temperature monitoring solutions for cryogenic liquid nitrogen containers

Proven, reliable performance down to -200 °C for liquid nitrogen tank temperature monitoring

Proven, reliable performance down to -200 °C for liquid nitrogen tank temperature monitoring

API raw pharmaceuticals, freeze-dried substances and human samples must be transported and stored in the glass phase at the lowest possible temperature. For this purpose, specialized dry liquid nitrogen tanks can be used to maintain temperatures at -196°C using liquid nitrogen (LN2.) Temperature monitoring of cryogenic tanks is not only challenging due to the extremely low temperatures, but also requires more complex operational procedures such as pre-cooling and refilling with LN2.

Temperature testing during storage and transportation in liquid nitrogen tanks is very important for raw pharmaceuticals, freeze-dried substances and human subjects, and its importance is mainly realized in the following aspects:

1

2

Some biomarkers or pharmaceuticals are extremely sensitive to temperature fluctuations. Excessively high or low temperatures may affect their safety or even lead to product contamination or hazards. Through temperature monitoring, temperature anomalies can be detected and avoided in time to ensure product safety.

3

4

When a product quality problem occurs, temperature monitoring can trace the temperature condition during the entire storage and transportation process, help to determine the responsibility and cause, and then improve storage and transportation management to reduce the possibility of quality problems.

Temperature testing during storage and transportation in liquid nitrogen tanks is very important for raw pharmaceuticals, freeze-dried substances and human subjects, and its importance is mainly realized in the following aspects:

The very low temperature of liquid nitrogen, typically around -196 degrees Celsius, means that temperature monitoring equipment and sensors need to be able to function and maintain accuracy at extremely low temperatures.

Liquid nitrogen tanks are usually hermetically sealed, which means that the temperature monitoring equipment needs to be able to be safely placed in the tank and the sealing of the tank must not be compromised in a way that would affect the accuracy of the temperature monitoring.

When monitoring temperature in liquid nitrogen tanks, there is a need to ensure that temperature data can be reliably transmitted, and consideration needs to be given to maintaining the stability of data transmission, especially in special transportation environments.

Temperature monitoring equipment operating in extreme environments needs to be highly reliable and able to operate stably for long periods of time without failure, which poses a challenge to the design and selection of the monitoring equipment itself.

In order to realize temperature monitoring, you can consider using temperature sensor/temperature probe or temperature recorder, which will be placed in the liquid nitrogen tank and stored or transported together with the samples, and continuously record the temperature during the whole process. During the storage and transportation process, you can use liquid nitrogen special & stable temperature probe and cloud platform technology to realize real-time monitoring and recording of temperature, and alert the relevant personnel to take timely measures when problems or abnormalities occur.

PDF/Bluetooth temperature logger with external probe

Temperature logger with external probe for real-time transmission.

Temperature logger with external probe for real-time transmission.

Suitable for refrigeration, ultra-low temperature and liquid nitrogen applications.

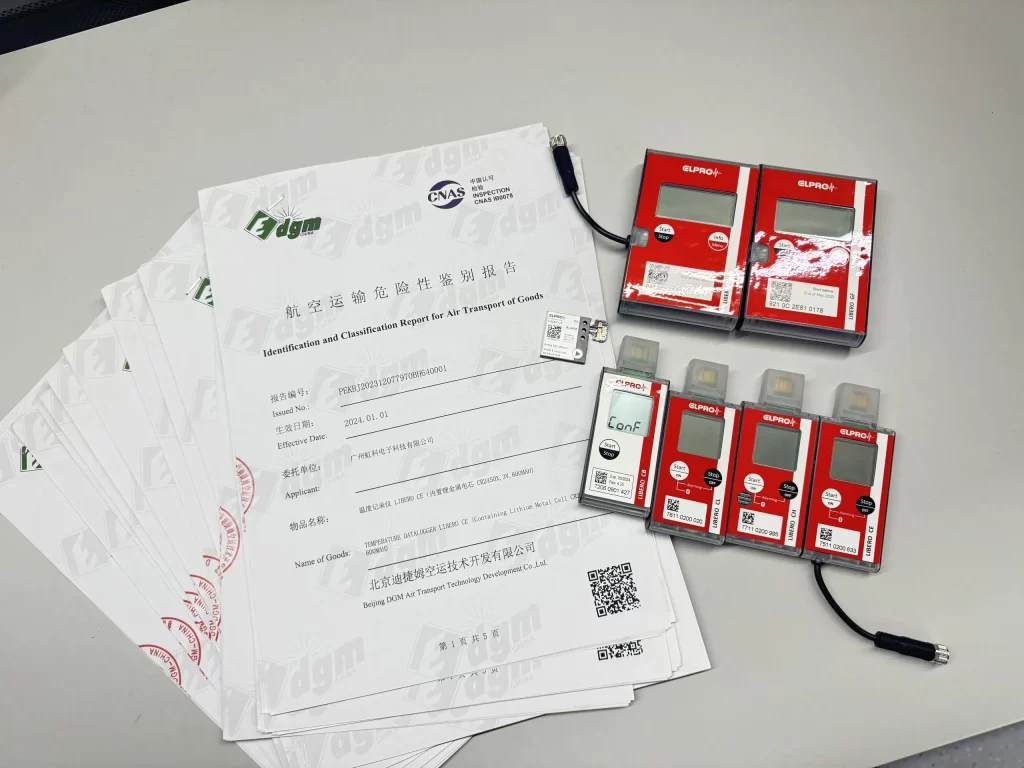

All of the liquid nitrogen tank transportation and storage temperature monitoring products provided by Honghong have obtained the aviation safety appraisal report (Cargo Transportation Condition Appraisal Certificate) from Beijing DGM and Shanghai Institute of Chemical Technology, and can be safely transported by air.

Our professional Honghong team will be the first to respond and provide you with the best service to solve all your problems.

Address: 3F, No. 99, Jingye 1st Road, Zhongshan District, Taipei City, Taiwan (Da Wan Technology Center Building)

3rd Floor., Dawan Technology Center Building, No. 99 Jingye 1st Road, Zhongshan District, Taipei City, Taiwan

©2025.hongtronics. All Rights Reserved.