Droplet generation research background

Droplet generation studies have developed rapidly over the past few years, mainly due to the significant advantages of the method, especially for high-throughput single-cell analysis: millions of single-cell-reactive droplets in an eppendorf tube are equivalent to >10,000 96-well plates with one cell per well.

The applications of droplet generation are far-reaching, ranging from drug discovery and diagnostics to food and cosmetics production and industrial applications such as paints. Microfluidic droplet generation offers significant cost savings compared to conventional production techniques.

Working Principle

Droplets are generated by precisely controlling immiscible liquids (typically water-based and oil-based) in microfluidic wafers with precise geometries using microfluidic pumps. There are typically three types of wafer geometries:

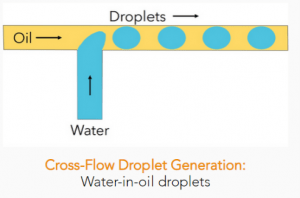

Crossflow:

T-connectors or Y-connectors in microfluidic wafers. For water-in-oil droplets; the oil sample (continuous phase) flows in one direction. The water sample (dispersed phase) flows into the oil sample at the T- or Y-joint. When the water sample is added to the oil sample, the shear force of the continuously flowing oil breaks the water sample into droplets. In this case, the droplet size is determined by the ratio of the flow rates of the oil and water samples flowing in the microfluidic wafer channel, as well as the viscosity, velocity and interface tension of the oil sample.

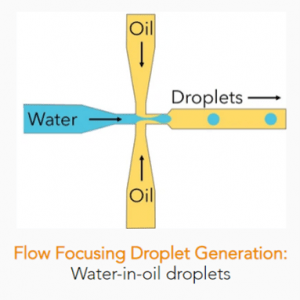

Stream Spotlight:

The “+” or X-junction geometry in a microfluidic chip. For water-in-oil droplets; the water sample (dispersed phase) meets the oil sample (continuous phase) at the junction, where the channel usually narrows. Similar to crossflow, the flow rate of the continuous phase (in this case oil) is usually higher than that of the dispersed phase (water). In this case, the droplet size can be increased by decreasing the flow rate of the continuous phase. In order to obtain oil-in-water droplets, the liquids are reversed.

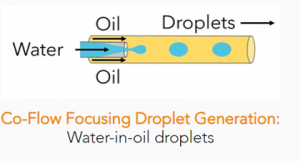

Co-current focusing:

The dispersed phase channel is enclosed within the continuous phase channel. As the dispersed fluid enters the continuous phase fluid, it is subjected to the shear forces of the continuous phase fluid until it eventually breaks up and forms droplets by dropping or ejecting.

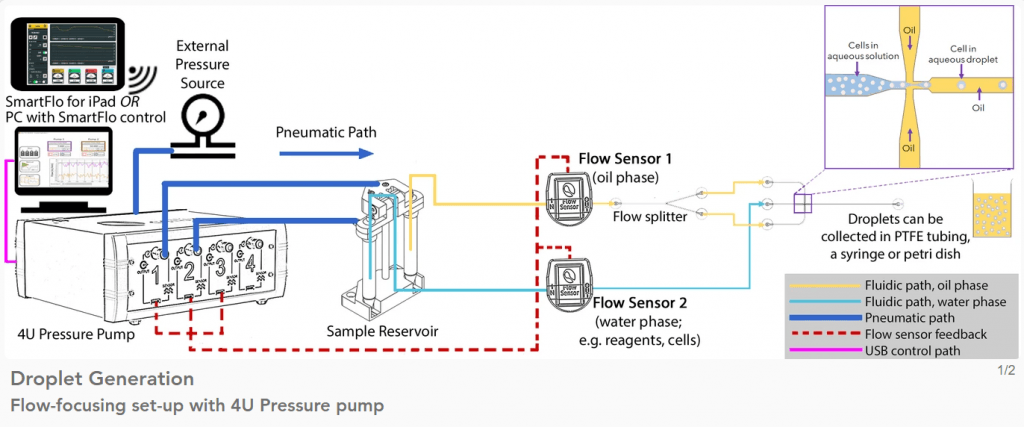

Working Principle

A PC or iPad with SmartFlo software is connected to the 4U pressure pump via USB cable or WiFi. An external air compressor pumps pressure from the two channels of the 4U pump into the liquid reservoir, where the fluid passes through two flow sensors connected to the pump and the chip, and the liquid in the different channels flows through the chip to form droplets.

Honghong Total Process Solution for Droplet Generation

We provide you with high quality instruments for your droplet generation process. Click on “Learn More” to go to the corresponding product page for more information.

Exigo Syringe Pumps

- Fast switching with response time as low as 50ms

- Purge mode with reversible flow direction or programmable design of perfusion mode (constant, ramp, step, sinusoidal)

- SmartFlo software on PC for stroke design.

- Plug-and-play flow sensor for active feedback and precise flow control

- Controlled by iPad mini or PC (LabVIEW, Matlab, Python, etc.), up to 4 pump modules can be independently controlled or programmed

- Connects to all microfluidic biochips using standard tubing

- ExiGo Microfluidic Syringe Pump

Unigo Pressure Pumps

- Short response and stabilization time

- Connected to the ExiGo microfluidic syringe pump, combining the best features of a pressure pump and a syringe pump in one microfluidic device

- Purge mode with reversible flow or programmable perfusion mode (constant, ramp, step, sinusoidal)

- Controlled by iPad mini or PC (LabVIEW, Matlab, Python, etc.), up to 4 pump modules can be independently controlled or programmed

4U Four Channel Pressure Pump

- Short response and stabilization time

- Purge mode with reversible flow or programmable perfusion mode (constant, ramp, step, sinusoidal)

- Plug-and-play flow sensor for active feedback and precise flow control

- The SmartFlo app runs on an iPad mini or LabVIEW interface and connects to 4 separate channels of a 4U pump, allowing simultaneous control and independent programming of each pump's flow conditions.

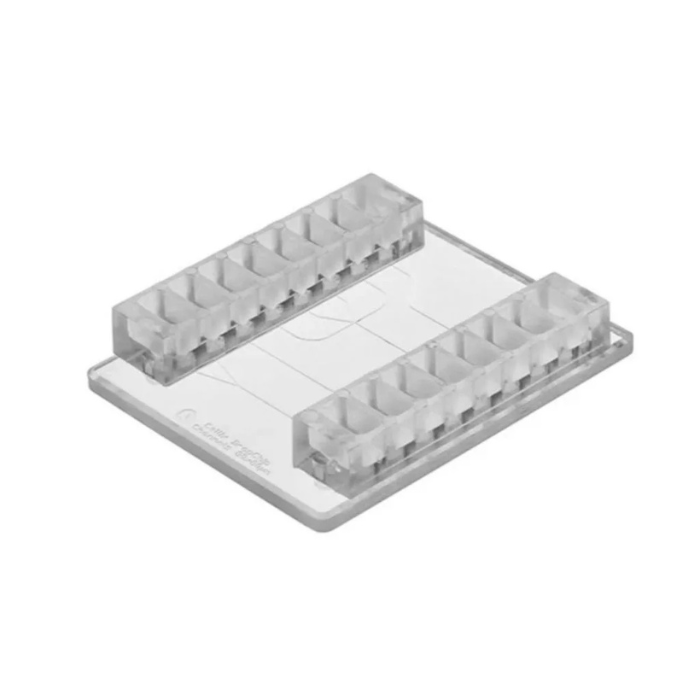

Dropchip

- Generates homogeneous, stable, monodisperse droplets using oil and water phases

- Cellular and Molecular Packaging Sequencing with Separators and Dual-Flow Focused Droplet Generators

- Reusable, with 1 diverter and 3 droplet generators, supports single or double injection

- Plug and play, standard 25G pin header for easy connection, no bulky connectors required

- Suitable for microfluidic syringe pumps and pressure pumps with precise and stable flow rate, suitable for immunofluorescence microscope applications.

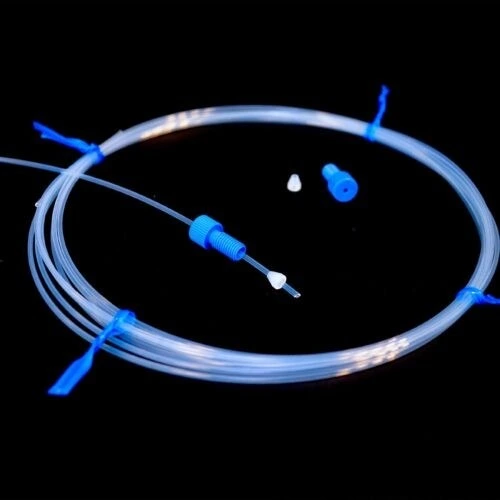

Honghong Droplet Generation Solution Accessories

We offer all the accessories needed for a complete experiment, including connection kits, flow sensors, vacuum compressors, wafer caps, etc.,.High-precision, product-specific fittings can help you complete your experiments smoothly, saving costs and improving efficiency.

Applications

- Cell/Protein Encapsulation and Sorting on Chip

- DNA sequencing for target selection/enrichment

- Sample/reagent mixing and on-chip reaction control

- DNA amplification

- biomolecular synthesis

- Diagnostic Chip

- Drug Discovery

Honghong will provide you with any support you need!

Our professional Honghong team will be the first to respond and provide you with the best service to solve all your problems.