preamble

In today's increasingly prominent consumer sovereignty, rapid changes in market demand has become the norm. Personalized and customized demand has become the mainstream of the market, and traditional mass production methods can hardly satisfy this fast-changing market demand. Digital technology combined with BI's analytical capabilities can realize flexible production, quickly respond to market changes, and accurately locate target customer groups. At the same time, through intelligent equipment, automated processes and data analysis, enterprises can accurately manage production resources, reduce waste, optimize inventory, further reduce costs and improve production efficiency. In addition, the digital platform also promotes knowledge sharing and innovation collaboration, accelerates the research and development cycle of new technologies and products, and brings unprecedented innovation vitality to the manufacturing industry.

Figure 1: Business Intelligence Data-Driven Decision-Making Tools

The Inevitability of Digital Transformation in the Manufacturing Industry

In today's increasingly prominent consumer sovereignty, rapid changes in market demand has become the norm. Personalization, customization demand has become the mainstream of the market, the traditional mass production mode is difficult to meet this rapidly changing market demand. Digital technology combined with BI's analytical capability enables flexible production, rapid response to market changes, and precise positioning of target customer groups. At the same time, through intelligent equipment, automated processes and data analysis, enterprises can accurately manage production resources, reduce waste, optimize inventory, further reduce costs and improve production efficiency. In addition, the digital platform also promotes knowledge sharing and innovation collaboration, accelerates the research and development cycle of new technologies and products, and brings unprecedented innovation vitality to the manufacturing industry.

BI in the Manufacturing Industry

1. production planning and scheduling optimization:By analyzing historical production data, inventory levels, order demand and other information through BI, manufacturing companies can more accurately predict future production demand, optimize production plans, and reduce inventory backlogs and production surpluses. At the same time, BI can also monitor the status of the production line in real time and automatically adjust production scheduling to ensure maximum utilization of production resources and improve production efficiency.

2. quality control and defect prediction: BI is able to integrate a large amount of data from the quality inspection process and use machine learning algorithms to identify abnormal patterns and potential defects in the production process, realizing early warning and pinpointing the source of the problem. This not only reduces the defective rate, but also shortens the problem solving cycle and improves product quality and customer satisfaction.

3. Cost containment and benefit analysis: Using BI tools, manufacturing enterprises can conduct in-depth analysis of multi-dimensional data such as raw material procurement, production costs, logistics costs, etc. to identify cost-saving opportunities, optimize supply chain management, and reduce operating costs. In addition, by comparing the profitability of different product lines and market regions, BI provides data support for resource allocation and strategic adjustment.

4. IOT data network analysis: The use of connected IoT devices can instantly collect a variety of data on the production line, such as equipment status, energy consumption, production volume, and so on. These data can be processed and analyzed by the BI system to provide real-time production monitoring and alerts, thus avoiding production interruptions or energy wastage.

5. Logistics tracking and scenario planning: By integrating logistics data, such as transportation time, transportation routes, cargo status, etc., BI system can provide real-time logistics tracking function for enterprises. This helps enterprises optimize their transportation plans, reduce transportation costs and improve logistics efficiency. At the same time, the BI system can analyze the logistics data in depth to help enterprises identify potential bottlenecks and risks in logistics, so as to formulate more effective logistics strategies.

The Transformation Path of DHL Temperature Control Solutions

In the field of drug transportation, temperature control is very important.DHL, a leading logistics service provider, faced the challenge of monitoring and capturing millions of data points generated during transportation in real time to troubleshoot problems. At the same time, their system was limited in the number of tables and data sources that could be merged to meet the in-depth data analysis requirements.

To meet these challenges, DHL introduced Domo, a BI platform.The introduction of Domo brought about a significant change for DHL:

1. Data manipulation: DHL members can use Domo to combine data in any way they want, and after importing all the data into Domo, they can do whatever they want with it.

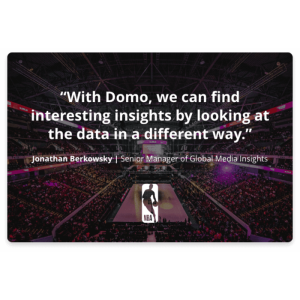

2. Translating information into action: At the same time, with Domo, DHL is able to visualize data that was previously unavailable and derive action plans from it, improving decision-making accuracy and efficiency.

Figure 2: Information Transformation Actions

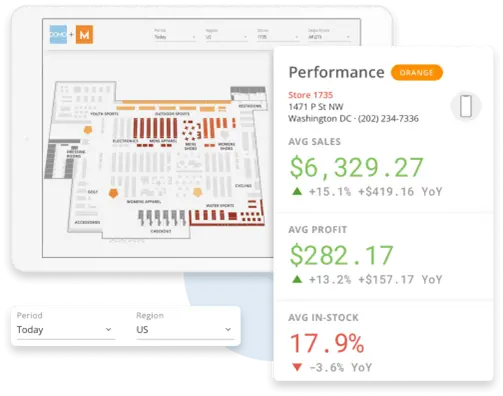

3. Intuitive visualization Visualization provides DHL with an intuitive overview of information, not only at the macro level, but also at the micro level of detail, enabling team members to understand details and respond faster.

Figure 3: Intuitive Visualization

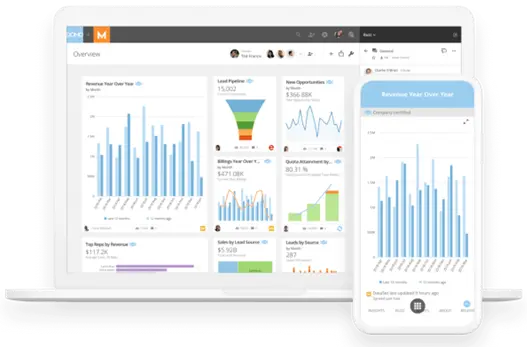

4. Precision targeting With Domo, DHL is able to pinpoint problems that were previously undetectable. For example, by creating heat maps, DHL can accurately recognize when a product has recurring problems on a particular transportation route, at a particular site, and take targeted action to solve the problem.

5. Enhance customer interaction Domo enables DHL to provide customers with transportation reports and visualizations that were previously unavailable. Employees are able to see the story behind the data more clearly and communicate it to customers, resulting in increased customer satisfaction and loyalty.

Figure 4: Enhancing Customer Interaction

In conclusion, it can be observed that the DHL temperature management solution through the Domo platform not only realizes a quantum leap in data processing, but also significantly improves operational efficiency and service quality, providing customers with a more transparent and efficient logistics service experience.

Conclusion

The application of BI in the manufacturing industry is a key part of promoting the transformation and upgrading of the manufacturing industry and realizing intelligent manufacturing. It not only helps companies optimize production processes, improve product quality, and reduce costs, but also enhances market sensitivity and customer response time, laying a solid foundation for sustainable development.

In the future, BI will be more deeply integrated into all aspects of the manufacturing industry, from supply chain management, production planning to marketing, to help enterprises realize intelligent and lean management, and to build an efficient, green and sustainable manufacturing industry.

Business Intelligence (BI) Analysis Tools-Domo Business Cloud Platform

Domo is a comprehensive business intelligence tool that integrates data, BI, and workflow and is used by 2,000+ well-known companies worldwide. It provides customized, real-time, interactive dashboards and 1000+ data interfaces, supporting custom application building and Buzz sharing. With cloud flexibility, anomaly management, embedded analytics, and best-in-class data governance and security, it helps enterprises simplify data integration, improve decision-making efficiency, and accelerate digital transformation.

Go to product page