CoreTigo Industrial Wireless Communications

Factory solutions

CoreTigo's solutions enable machines and production lines to do more by cost-effectively expanding their flexibility and capacity.Intelligent, ultra-reliable wireless communications in the plant are enabling previously impossible applications that drive operational efficiency, production and machine optimization, improved adaptability, sustainability and smarter business management.

Learn about CoreTigo products

Solutions Manual

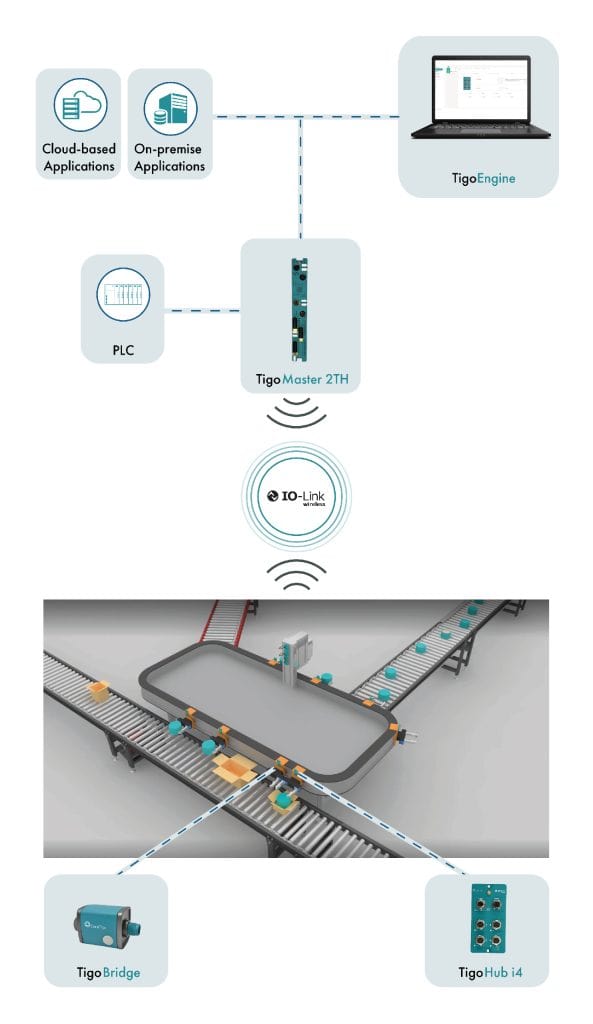

Transportation tracks and conveyor systems

Motion independence - for high production flexibility and throughput

Wireless and contactless communications on conveyor systems are critical to creating fully automated, innovative and competitive machine designs for packaging, assembly, logistics and material handling that were not possible before.

CoreTigo's IO-Link wireless communications solutions are revolutionizing the industry by providing real-time, cable-grade wireless connectivity for sensors and actuators on dynamic mobile machine components.This allows equipment such as grippers, pumps and valves mounted on movers or separate units within the conveyor system to perform actions seamlessly while in continuous motion.

Wireless Advantages of Transportation Tracks

Adaptable, Efficient, Sustainable

Eliminate manual and automatic conversion of multiple products/packages and small batches

IO-Link Wireless System Integration

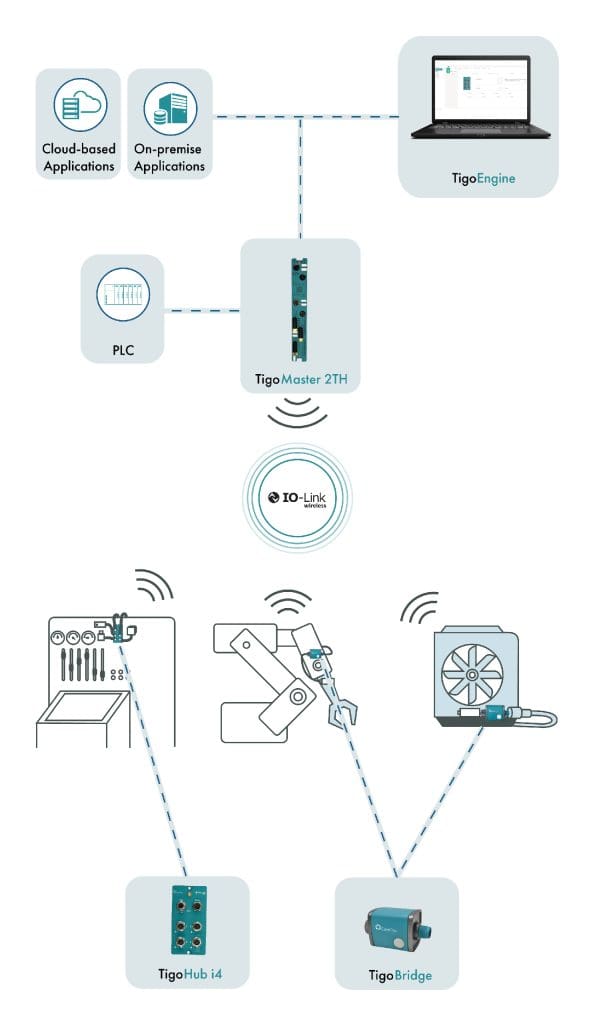

CoreTigo's solution provides real-time data connectivity to sensors and actuators on individual movers without the need for additional external robots or equipment. Each mobile is equipped with an IO-Link wireless multiport hub (TigoHub) or an IO-Link wireless bridge (TigoBridge), which provides multiple sensors and actuators with a connection to the mobile itself.

The IO-Link Wireless Master (TigoMaster) communicates wirelessly with all devices on mobile devices, connects to PLCs for automation control, and connects to the Internet of Things and enterprise IT-level servers for data monitoring.CoreTigo's unique antenna solution enables a highly reliable, scalable, and secure solution for wireless communication with hundreds of mobile devices and equipment. wireless communications with hundreds of mobile devices and equipment.

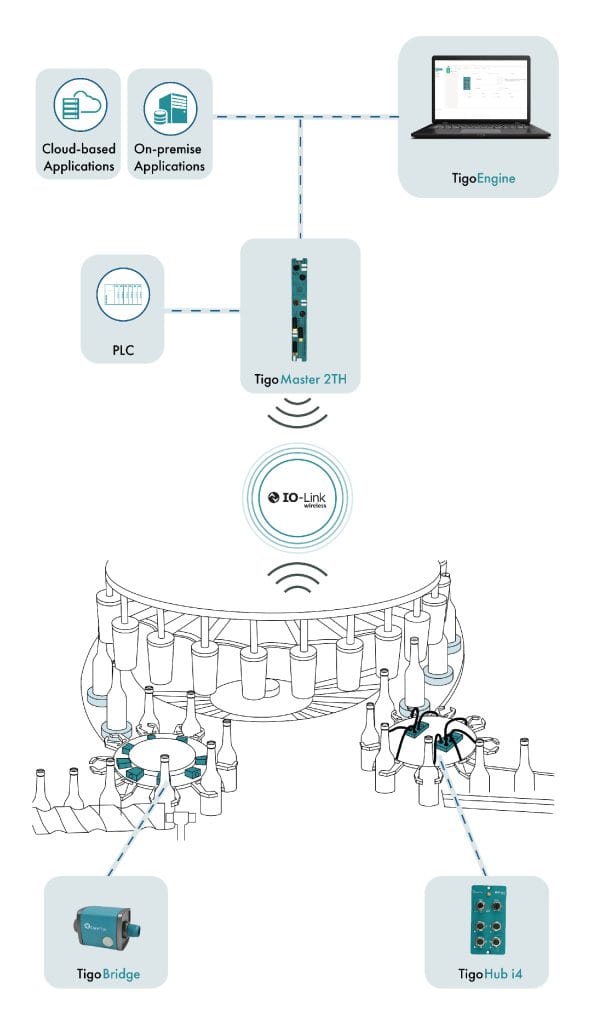

Turntables and Turntables

Efficient wireless connectivity supports adaptive and simplified design

Easily add connectivity to fast rotating equipment on turntables and dials with an industrial-grade wireless real-time communication solution. Without unnecessary cables or slip rings, you can add sensors (e.g., load cells, volume sensors) and actuators (e.g., valves, servo motors, grippers) to dynamically rotating machine components such as tables and turntables.

Products are processed in the most flexible manner while in constant motion, eliminating the need for manual changeovers while reducing maintenance and deployment efforts.

Wireless Advantages of Turntables and Dials

Reduced conversion, multiple product and package designs, simplified deployment and maintenance

Simple and flexible operation

CoreTigo's solutions provide real-time wireless connectivity to multiple sensors and actuators on rotary tables and turntables in continuous motion.

The sensors and actuators on the rotary device are connected wirelessly to one of the following devices:

.TigoBridge - Direct and seamless connection, no need to integrate with sensors or actuators, turning them into IO-Link wireless devices.

.TigoHub - Multiple sensors and actuators can be connected to CoreTigo's TigoHub, which converts four to six digital, analog or IO-Link devices in parallel to IO-Link wireless.

.Embedded Modules- Integrated IO-Link wireless device design without external adapters.

TigoMaster (IO-Link Wireless Master) allows real-time transmission of device data and control to and from automation PLC's. Master supports a wide range of industrial Ethernet protocols (e.g. Ethernet/IP, EtherCAT, Profinet, or OPC-UA) and can send monitoring and control data to IIoT platforms or any other application. The Master is fully flexible and easy to deploy, as no communication cables are required between the Master and the rotary devices on the turntable and table.

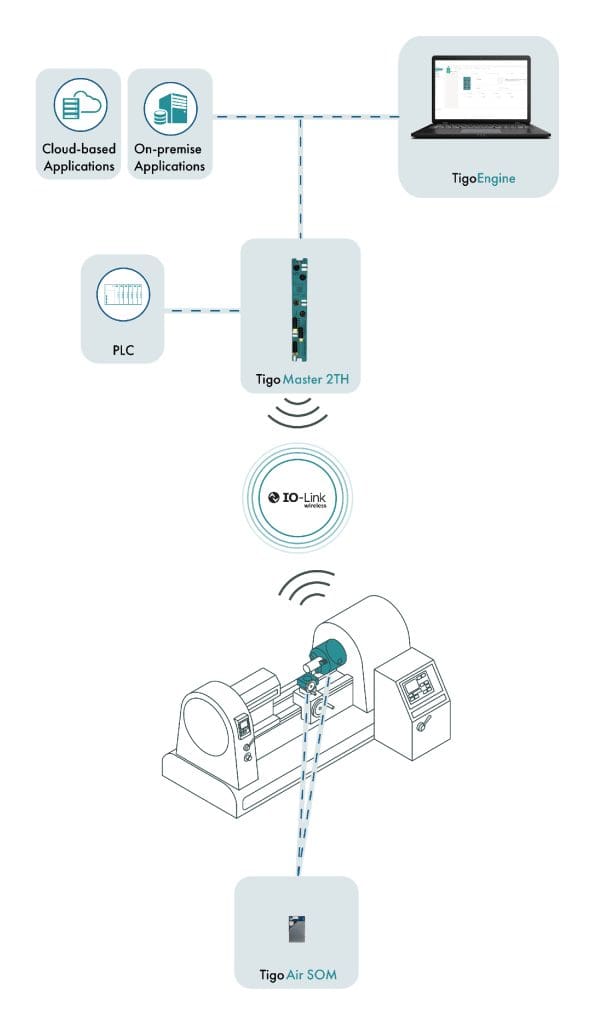

Intelligent beds

IO-Link Wireless Communication for Smart Machine Tools

Taking tooling machines (CNC, grinding, milling) to the next level of intelligence by integrating sensors and actuators throughout the entire machine-rotary tool (jaws, vise, taper, cylinder) through a powerful wireless communication solution.

CoreTigo's IO-Link wireless solutions enable real-time monitoring and control with all the reliability of cable-grade communications for industrial conditions (thousands of RPM, harsh and noisy environments).The most accurate and powerful solution ever designed.

The collection of data (e.g. force, vibration, temperature) at the clamping/machining point during machining enables machine optimization, precise tool setting, predictive maintenance, improved quality and safety.

Benefits of Wireless Pair Bed

Smarter machine operation and maintenance

IO-Link Wireless System Integration

- Terminal Equipment Integration

CoreTigo's TigoAir SOM module can be integrated directly into sensor devices and connected to sensors or actuators like a smart fixture. A specially designed antenna provides the connection and a battery provides the required power.

• Machine Integration

Many wireless devices can be integrated into the machine: swivel ends, mobile units and fixed platforms. Standard IO-Link devices can be connected via TigoBridge, while other analog/digital devices can be connected via multi-port I/D hubs and TigoBridge.

- Complete Solutions

All wireless devices communicate with TigoMaster via the IO-Link wireless protocol. TigoMaster communications are automated at the OT level with PLCs via the Industrial Ethernet protocol or OPC-UA, and at the IT level with enterprise applications or the cloud via the MQTT or OPC-UA protocols, for IIoT, Data analysis and monitoring.

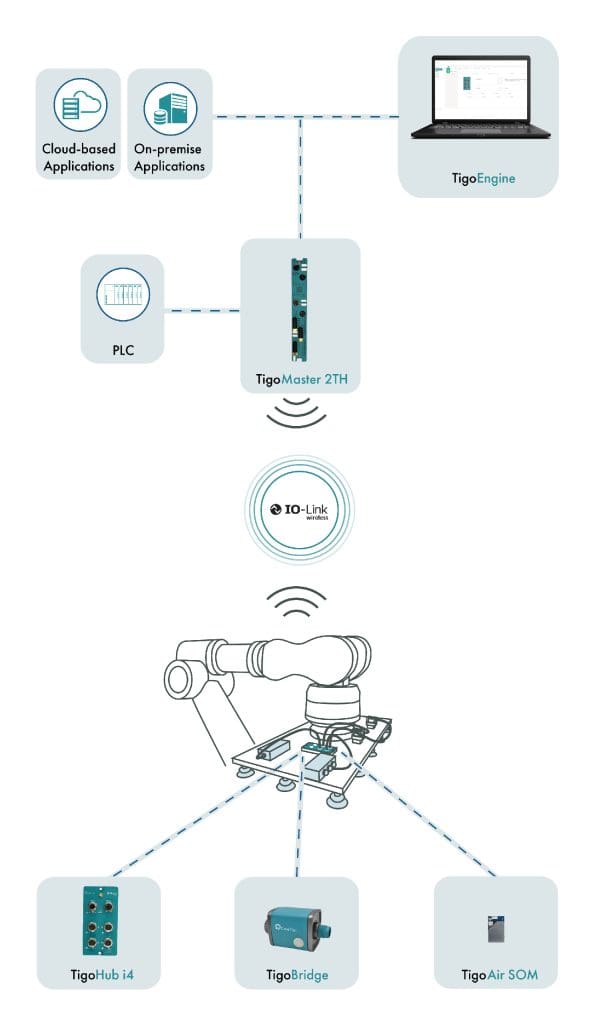

Wireless Robot

IO-Link Wireless for Wireless Robot and Collaborative Robot Communication

Enabling wireless communications for end-of-arm devices for robots and collaborative robots solves a number of challenges. Cables in constant motion are prone to breakage and abrasion, and resistance to bending and torsional loading increases the cost of the cable.

Multiple units (e.g., clamps, valves, sensors) need to be individually wired for data communication, leading to wiring and installation complexity. Cables often impede a robot's range of motion, limiting flexibility. Heavier payloads require larger robots that are more expensive, slower and take up more floor space in the machine/work cell area.

CoreTigo's industrial-grade IO-Link wireless solutions enable robotic end-of-arm devices to realize the low-latency, reliable and interference-free communications required for real-time wireless control and monitoring.

Benefits of wireless technology for robots

Cable-level connection, not limited by cables

Full connectivity of robot end-effectors

The implementation of wireless control and monitoring robotics solutions can be realized in two key ways:

.Embedded IO-Link Wireless Module

CoreTigo's TigoAir wireless device connection SOM (System on Module) is integrated at the end of the arm at the device/connector, providing an IO-Link wireless connection and receiving power directly from the robot arm.

.External IO-Link Wireless Hubs and Bridges

Other end-effectors can be retrofitted to any robotics/collaborative robotics platform using CoreTigo's TigoBridge or TigoHub, allowing any IO-Link, analog and digital device to be seamlessly converted into an IO-Link wireless device with no special design or prior integration.The TigoBridge and TigoHub are separate units with IP67 enclosures, allowing them to be used as-is with no integration effort. TigoHub as standalone units with IP67 enclosures allow them to be used as they are, with no integration work required.

In both cases, the IO-Link wireless device is connected wirelessly to the TigoMaster, which can be placed on the robot itself or in a control box on the production line, controlling numerous end-effectors and robots.

TigoMaster transmits data and control commands in real time to and from PLCs via the preferred industrial Ethernet protocols such as Ethernet/IP, EtherCAT, Profinet or OPC-UA. It can also send monitoring data to IIoT and other enterprise applications.

Condition monitoring and machine modifications

Data collection via wireless connection

Data needs to be collected anywhere throughout the plant. In addition to optimizing manufacturing planning and processes, accessing data from sensors throughout the plant allows for powerful analysis and decision-making.

Data-based applications are leading to smarter solutions and better efficiency and cost reduction planning.

Benefits of Wireless Status Monitoring

Factory-wide visibility

Simple and scalable

CoreTigo's TigoBridge IO-Link wireless bridge:

The Direct and seamless connection, no need to integrate with any IO-Link device.

The Convert off-the-shelf hubs to IO-Link wireless - Convert connected digital/analog sensors

Non-IO-Link and IO-Link sensors can be connected to CoreTigo's TigoHub:

The Converts up to 6 digital sensors in parallel to IO-Link Wireless

The allows for mixed IO-Link, digital and analog sensor connections

The Support for off-the-shelf equipment

The TigoMaster.

The Real-time data transfer and control with automation PLCs

The Supports preferred industrial Ethernet protocols (e.g. Ethernet/IP, EtherCAT, Profinet or OPC-UA)

The TigoEngine engineering tool enables efficient setup of IO-Link wireless masters and devices.

The Supports installation, configuration and monitoring of the IO-Link wireless system

The provides access to monitoring, analysis, visualization and automation tools.

The Analyzing Process Data

The Includes an advanced MQTT publisher for IOT and other enterprise applications locally or in the cloud.

TigoCounter:

The Connects to digital output and enables object counting and wireless data transmission.

The Fully integrated counting and IO-Link wireless devices in one device

The For applications such as product object counting, motor revolution counting, or power consumption measurement.

Honghong will provide you with any support you need!

Our professional Honghong team will be the first to respond and provide you with the best service to solve all your problems.