Intelligent Battery Management System (BMS)

Battery Management System (BMS)A key component of modern battery technology, its main role is to intelligently manage and maintain the status of each battery unit. the BMS can instantly monitor and control the charging and discharging process of the battery, effectively preventing over-charging or over-discharging phenomena, thus extending the battery life and ensuring its safety and stability.With the boom in electric vehicles and renewable energy, BMS has become a key technology for improving battery performance and reliability.Now that Li-Ion batteries have become the mainstream of energy storage applications, the importance of BMS has become more and more prominent.

Top - Battery Management System (BMS) Core Controller Functions

Typically, BMSs use a variety of protocols to connect battery monitoring modules, stack controllers, and power interfaces, supporting protocols such as Modbus and Ethernet.CAN (Controller Area Network) ProtocolWith its stability, real-time performance, fault tolerance and noise immunity, it has become the communication method of choice for many energy storage applications.In a BMS, the CAN protocol effectively transmits critical data to ensure efficient system operation.

Fig. 1 - Application of BMS in Wind Energy Storage

BMS Core Application Areas

- Electric Vehicle Applications

The BMS is one of the core components in electric vehicles, and plays an important role in all kinds of electric vehicles such as passenger cars, commercial vehicles, trucks, etc. It is also widely used in electric machinery, such as electric forklifts and golf carts, etc. In these applications, the battery pack usually communicates with the battery control module through a CAN bus to ensure the safe and efficient operation of the battery. Battery packs in these applications usually communicate with the battery control module via a CAN bus to ensure safe and efficient battery operation.The BMS not only ensures the safety of the EV battery, but also improves the energy efficiency and performance of the entire vehicle. - Grid Electricity Infrastructure

In the power infrastructure, battery packs provide backup power to the grid or act as a safeguard against power fluctuations.BMS are used in areas such as cell phone towers, AC substations, Internet infrastructure equipment, aviation ground support systems, communication towers and weather stations, and play an important role in decentralized energy systems, such as solar and wind power plants.The BMS helps to balance the load on the grid and enhance the stability and reliability of the power system.

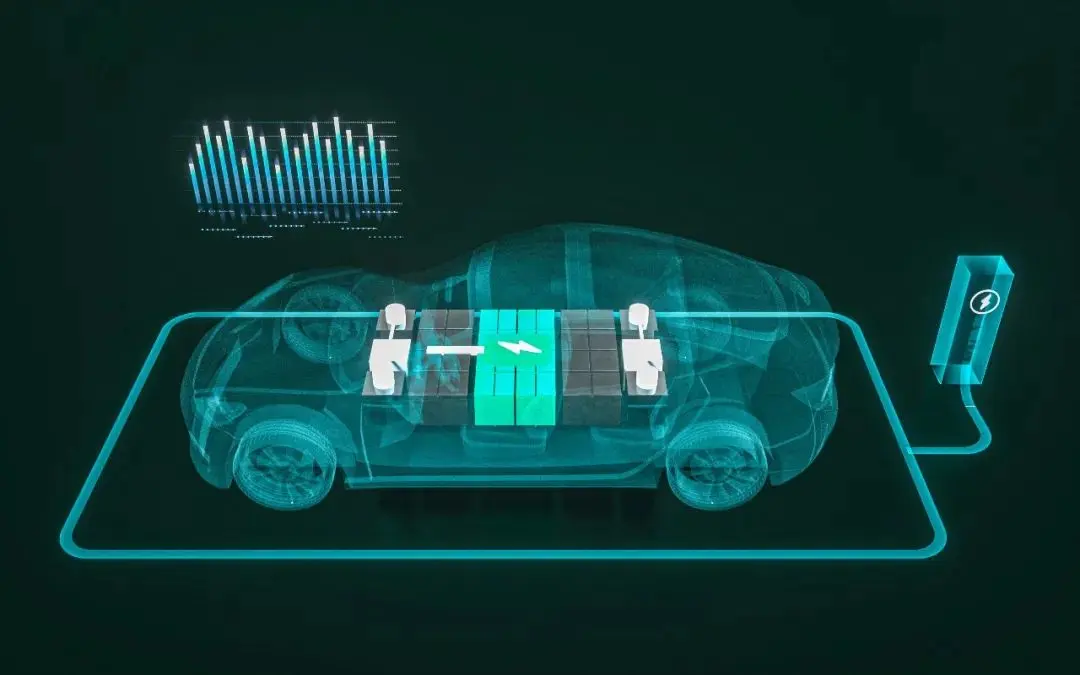

Figure 2 - EV Battery Structure under BMS System

BMS communication protocol and its application

Fig. 3 - BMS monitors the charging status of EVs in real time

To ensure that the Battery Management System communicates smoothly with other systems in the vehicle or with the Power Storage Converter (PCS), the BMS usually follows the following standardized high-level communication protocols:

- iso 11898-1:2015This is an international standard for CAN bus data link layer and physical signaling, which mainly defines the structure of a CAN data frame, including frame start, frame end and data fields.

- SAE J1939-21: The protocol is widely used in the automotive industry and specifies data link layer parameters such as data transfer rate and frame format.

- CAN 2.0B: A version of the CAN bus that supports 11-bit standard frames and 29-bit extended frames for communication between battery monitoring modules, stack controllers and power interfaces in BMS.

- BMS-CAN protocol: A customized protocol for battery management systems that defines the communication between the BMS and the vehicle's CAN network, including data format, frame ID assignment and message definition.

- Protocol between the storage converter and the BMSThe standard, developed by the China Chemical and Physical Power Supply Industry Association, specifies the requirements for CAN-based communication layers between BMS and PCS.

These protocols ensure that the BMS effectively monitors and manages the battery cells and accurately transmits and receives data to enhance the safety and operational efficiency of electric vehicles and the electrical infrastructure.Following standardized protocols, the BMS is able to communicate seamlessly with equipment from different vendors.

Application of CAN bus in BMS

Figure 4 - BMS Data Management and Network Connectivity

The application of CAN buses in BMS covers the following key aspects:

- Data Acquisition and Monitoring: The CAN bus collects real-time battery pack parameters such as voltage, current, and temperature, and monitors battery status, including state of charge (SOC), state of health (SOH), and state of power (SOP).

- Battery equalization managementThrough the CAN bus, the BMS can realize the equalization control among battery cells to maintain the consistency of battery packs and improve the overall performance.

- Troubleshooting and AlarmsWhen overcharging, overdischarging or temperature abnormality is detected, the BMS will send an alarm through the CAN bus to notify the system to take action.

- Control of Command Delivery: Sends control commands to actuators, such as contacts and relays, to realize battery charging and discharging management.

- System Integration and Data Sharing: The CAN bus is part of the vehicle's internal network, allowing the BMS to communicate and integrate with other systems in the vehicle, such as the motor controller and on-board charger.

- Application of standardized protocolsThe application of standardized protocols, such as BMS-CAN Protocol V2, improves interoperability between BMSs from different vendors.

- Definition of Data Format: Includes formats for data parameters such as total voltage, total current, SOC, SOH, etc., and covers definitions of information formats such as charging/discharging limit current and voltage.

- Remote Data Request: Remote data request using the remote frame function of CAN enhances the flexibility of data acquisition.

- Auto-Reset Function: The automatic retransmission function ensures the integrity and reliability of the data in the event of an error in data transmission.

The application of these CAN buses significantly enhances the safety, reliability, and extended life of the battery pack.The CAN bus has become a key component in the BMS.

Key Tools for BMS Development and Testing

Figure 5 - Application of BMS in Solar Charging Station

In BMS development and testing, theKvaser's CAN Interface and Data LoggerThe tools provide strong support. These tools measure, collect and transmit data on the CAN bus in an efficient manner to support BMS monitoring, analysis and decision making. In addition, Kvaser tools offer the following advantages:

- increase efficiency: Early detection of faults and predictive analysis.

- Reduced maintenance costs: Effectively reduce maintenance costs through monitoring and automation.

- Improve system performance: Supports multi-battery module monitoring, which helps to improve the overall performance of the BMS system.

All CAN interfaces and data loggers are available for automotive and commercial vehicle applications and support a wide range of industry protocols, such as NMEA 2000®, J1939, CANopen and DeviceNet, to meet the needs of all industries.The use of professional development tools can accelerate the R&D process of BMS and enhance product competitiveness.

Product Recommendation

Kvaser U100

- High performance CAN interface for harsh environments

- Rugged and durable with IP67 rating

- Supports USB connection for easy installation

- Suitable for electric vehicles, industrial automation, etc.

Kvaser Air Bridge Light HS M12 (FCC)

- Wireless CAN solution eliminates cabling constraints

- M12 interface for industry standard applications

- Simple pairing, ready to use right out of the box

- Suitable for BMS systems that require wireless communication.