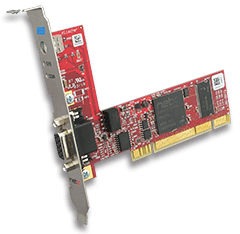

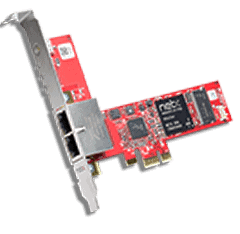

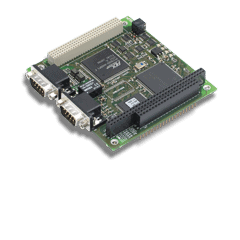

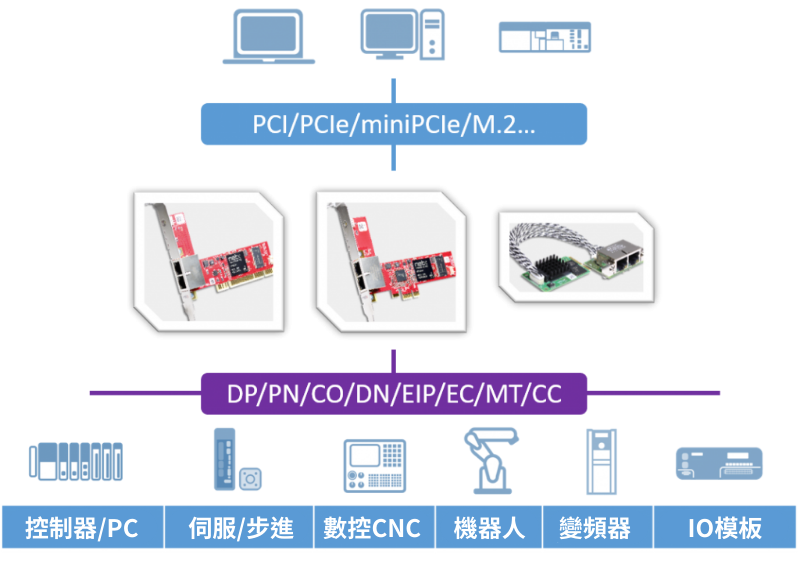

Efficient PC-based communication solutions

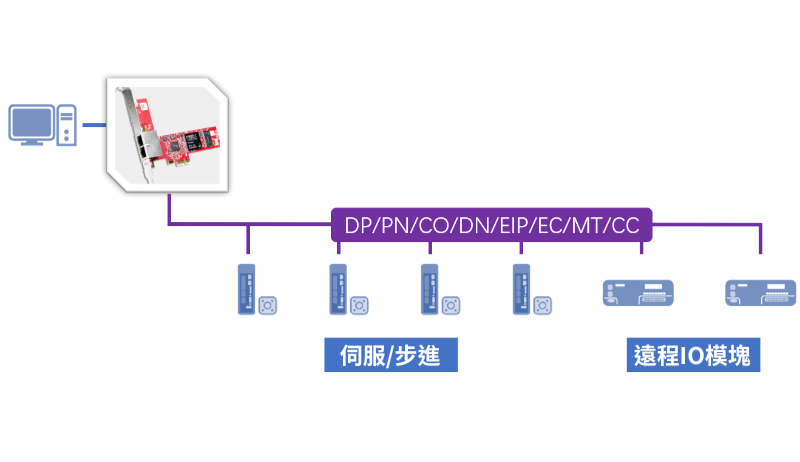

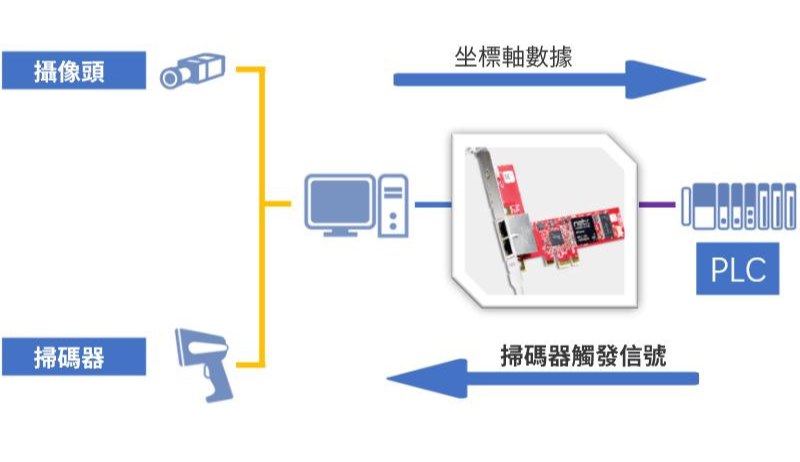

Supports multiple industrial buses and Ethernet protocols, designed for automation, realizing flexible protocol switching on a single platform and adapting to a variety of industrial needs. With excellent data transmission performance and low latency, it is widely used in machine control, industrial manufacturing and process monitoring, greatly enhancing system integration and operational efficiency.

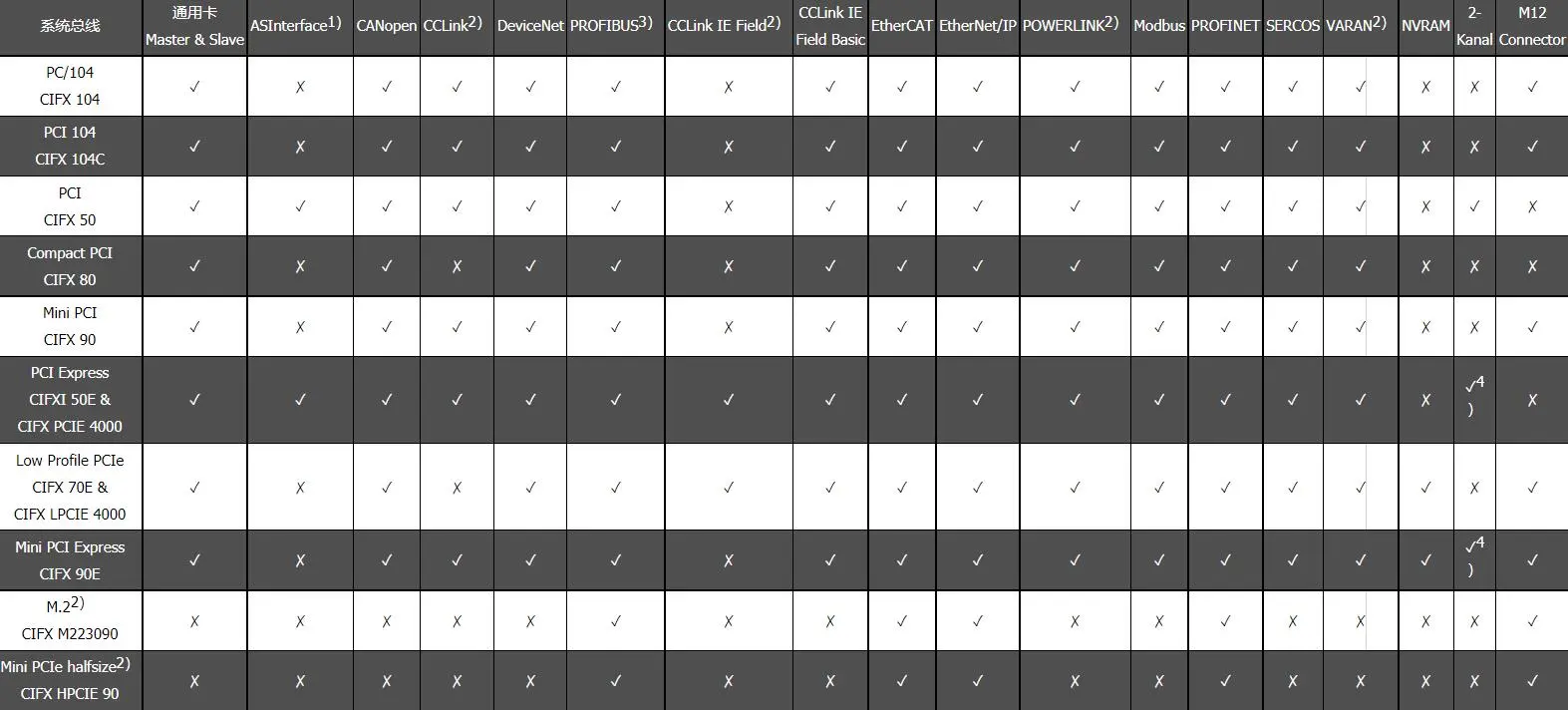

- Multiple protocols supported: EtherCAT, PROFINET, CANopen, PROFIBUS, EtherNet/IP...

- Support multiple interfaces: PCI, miniPCI, PCIe, M.2, PCI104, PC/104, CPCI.....

- Can be used as master or slave