What is a Screw Conveyor?

Screw conveyor is a kind of continuous conveying equipment made of steel, which can be used for conveying chemical and building material products such as powder or solid granule with higher temperature, commonly known as “winch”. In the technical field of material conveying equipment, the traditional screw conveyor occupies a large proportion.

It can convey horizontally, inclined and vertically, and adopts a closed conveying structure, which is especially suitable for conveying dusty materials. Because of the advantages of no dust emission, accurate material conveying, simple conveyor structure, convenient operation, green and high efficiency, the screw conveyor is widely used inMinerals, food, energy, feed, construction and chemicals.It has been widely used in the industry.

Why does a screw conveyor need a relay?

Screw conveyors are simple in structure and easy to operate, but in the process of conveying materials onlyRun in the specified directionIf the system is connected in wrong phase sequence when starting up, it will cause the rotating direction of the blades on the rotary shaft to change. At this time, the screw conveyor runs in the reverse direction, which will easily cause damage to the blades, deformation of the shell, and the motor that drives the rotary shaft will be easily burned due to the blockage.

In addition, when the three-phase power supply in the line is out of phase, the three-phase current is unbalanced or too large, which will cause the equipment in the line, such as the motor to burn out quickly. In this way, the screw conveyor will not be able to work normally and affect the production process in an orderly manner.

Honghong Solutions - tele Phase Sequence Monitoring Relay

In order to ensure the safe and orderly operation of the screw conveyor, so that it stops running when the phase sequence of the power supply is abnormal or out of phase, to avoid the impact on the performance of the equipment, you can use theHK-E1PF400VSY01 Phase Sequence and Phase Loss Monitoring Relay。

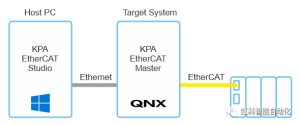

Phase sequence monitoring relays are mainly used for phase sequence and phase loss monitoring and protection.

When the phase sequence monitoring is normal, the relay will operate and the three-phase circuit will run normally. When the phase sequence and phase loss monitoring is not normal, for example, when any one of the three-phase circuits is out of phase, the output relay breaks down and the three-phase circuits enter into the protection state, which can effectively prevent the wrong reverse movement of the screw conveyor equipment and avoid the danger of the transmission load caused by the phase loss.

Characteristic parameters:

- Power supply voltage = measured voltage;

- Accuracy: Basic accuracy: ≤5% (nominal value); Adjustment accuracy: ≤5%; Repeat accuracy: ±2%;

- Two LEDs are used for continuous status monitoring;

- Self-extinguishing plastic material, protection class IP40;

- Can be mounted on DIN rail TS 35 according to EN 60715, easy and quick;

- 1 switching contact

- Width only 17.5 mm

Functional Description

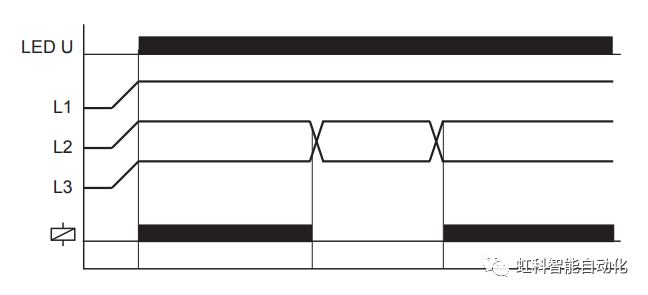

01 Phase Sequence Monitoring

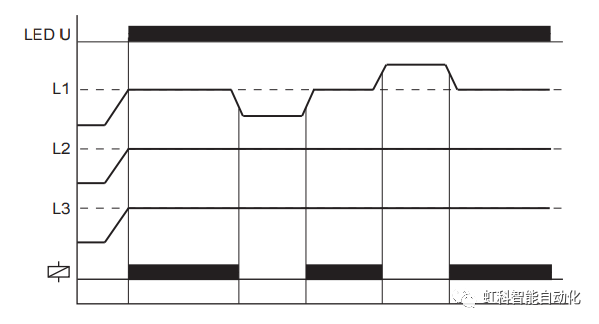

When all phases are connected in the correct sequence and the measured asymmetry is less than a fixed value, the output relay switches to the ON position (yellow LED illuminates). When the phase sequence changes, the output relay switches to the OFF position (yellow LED does not light up).

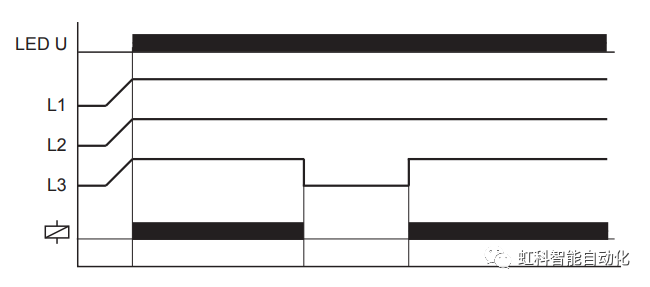

02 Phase Fault Monitoring

If one of the phases fails, the output relay R is disconnected (yellow LED does not light up).

03 Phase asymmetry monitoring

When the asymmetry exceeds the setting of the ASYM-regulator, the output relay R switches to the off position (yellow LED does not light up). The reverse voltage of the electrical equipment (e.g. d-motor continues to run on only two phases) does not affect the disconnection.

Honghong has launched a variety of relays: time relays, monitoring relays, switching relays and other energy efficient management solutions!