Risk Assessment of Shock Vibrations Using MSR165 Data Logger with Accelerometer in CTI Research Project

01 Background of the Project

The volume of artwork being transported around the world continues to grow. During transportation, paintings are exposed to many stresses and risks, such as shock and vibration. Paintings can be damaged when moving them in museums, loading and unloading boxes, trucks traveling on bumpy roads, and moving cargo at airports.

Back in May 2012, CTI presented ”Risk Assessment and New Prevention Strategies for Shock and Vibration in the Transportation of Fragile Paintings” (CTI).www.gemaeldetransport.chThe use of the MSR165 data logger was considered for the first time in the research project, with the aim of finding a new way to classify shocks and vibrations occurring during transportation, assess the associated risks, and develop preventive strategies to determine tolerances. The results of the study have provided a wealth of new information to improve risk assessment and existing transportation and packaging issues. A follow-up project is also underway, aimed at developing optimal vibration protection strategies for the transportation of fragile paintings.

The interdisciplinary research team consisted of experts from the University of Applied Sciences (BFH)/University of the Arts (BUA) in Bern, Switzerland, in conservation and restoration (KUR) and the Institute for Electrical and Mechanical Systems (ifms). The project is also supported by four commercial partners, including a Swiss insurance company and three leading Swiss art transportation companies. As partners with practical experience, experts from Switzerland's major museums are also involved in the project and can offer their practical experience in this field.

02 Progress of the Project: Comparative Measurement of Existing and New Transportation Packages

The choice of packaging type depends on the type of painting, the transportation route and the mode of transportation. In practice, countless methods and combinations of materials have been used to minimize the shock and continuous vibration of paintings during transportation - from simply wrapping paintings in bubble wrap to the use of complex double-insulated boxes. Previous studies have found that some packaging is ineffective and in some cases may even increase the vibration to which the painting is subjected.

Therefore, in this research project, the vibration damping properties of various buffer materials were tested using an electric vibration testing device (vibrator). In addition, drop tests were conducted to evaluate the response of the paintings to impacts. Then, the business partner (transportation company) developed various prototypes based on the test results and redesigned the vibration damping system.

In order to compare the vibration damping capabilities of the newly developed prototype and the existing packaging system under real environmental conditions, several tests were conducted on trucks equipped with air suspension. Each truck was loaded with four identical test paintings, each with a different packaging method, to ensure that all packaging types were subjected to virtually the same stresses on routes covering country roads, highways and city streets.

03 Test Method: Original Customized Measurement System vs MSR165

The previous project used a customized, individually assembled measurement system to record the impacts and vibrations of the paintings inside the boxes during transportation. The system consisted of a control unit, an external battery and a number of external accelerometers. This allows continuous, high-precision measurements (up to 2,000 Hz) to be taken over several days (with a large battery capacity and up to 32 GB of memory, depending on the hard disk used).

Although the system has high performance and accuracy, it is not feasible for practical applications.Firstly, the separate components are very expensive and complex to use (requiring customized application software), and secondly, it is very bulky. As a result, it was not possible to package the system with the painting, but rather it had to be placed in its own technical box and connected via a cable to the acceleration sensor mounted in the painting's box.Therefore, the ideal alternative is to use MSR165 RecorderThe product will be secured to the test paintings, the outside of the package, and the cargo area of the truck.

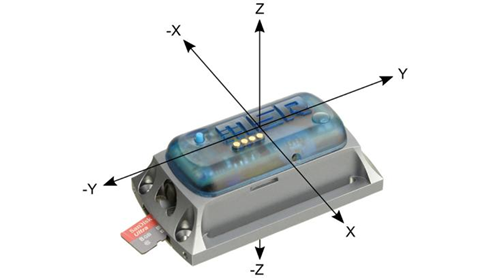

The MSR165 DataCORDER's small form factor and light weight, as well as the fact that the sensors and power supply are integrated into the recorder, allow it to be mounted directly on the frame of the painting or inside the packing box without the need to lay cables, which can cause obstacles when transporting the packing box. In contrast to previously used measurement systems, the MSR165 DataCORDER can be easily recharged via the USB interface of a laptop, and at the same time the measurement parameters are programmed in such a way as to simplify operation considerably.

The MSR165 has only been used to measure impacts and vibrations on the frame of a painting or the inside of a box. However, with its four additional analog inputs, the device can be configured to connect another single-axis acceleration sensor so that the vibrations of the material supporting the painting can be measured. However, this third-party sensor requires an additional, self-developed external power supply.

It is not only mechanical influences that can cause damage to paintings, but also climate change that poses a potential risk. Therefore, the configuration of the equipment used in the transportation measurementsConsider adding a built-in humidity sensor so that ambient humidity and temperature, as well as shock and vibration inside the box, can be additionally recorded with a single device.

A total of 13 MSR recorders were used for the test.The recorder is equipped with an internal 3-axis acceleration sensor, an internal humidity sensor and a 4GB micro SD card slot for memory expansion. The recorder can still record up to 3 days of continuous measurements (without threshold) at a maximum measurement rate of 1,600Hz during transportation.Reducing the measurement rate further extends the maximum execution time. To be able to fully utilize the storage capacity of the SD card, the ECORDER should be used with the Loop Storage mode enabled.

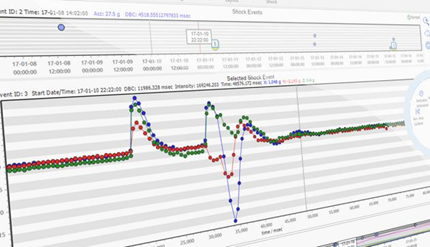

This means that when the SD card is full, the earliest data will be overwritten and deleted automatically. Therefore, it is necessary to determine the maximum possible measurement time in advance, so that the expected start time of the transfer is set as the start condition and the time when the SD card is full is set as the stop condition. The measurement data is then evaluated using the MATLAB software.

To evaluate the vibration damping capabilities of various types of packaging, tests measured how vibrations were transferred from trucks and packages to the test paintings. This includes determining and comparing maximum values, RMS (root mean square) levels and dominant frequencies. The test results will reveal the strengths and weaknesses of each packaging method and highlight further improvements that can be made.

Click to learn >> MSR165 products