Laser Texturing - Background

With the rapid development of aerospace, optoelectronics, and semiconductor manufacturing industries, traditional mechanical processing methods have become increasingly difficult to meet the needs of high-end industries. Therefore, people began to explore more advanced processing methods. Laser as a light source with high brightness, strong directionality, good monochromaticity, strong coherence and other characteristics.

Applications in processing began in the mid to late 20th century. Today, ultrafast laser technology continues to break new ground, and laser processing is moving toward a new level of sophistication.Higher precision, faster speed, better quality, more diversified applications.The development in the area of AndLaser texturing is one of the new applications.

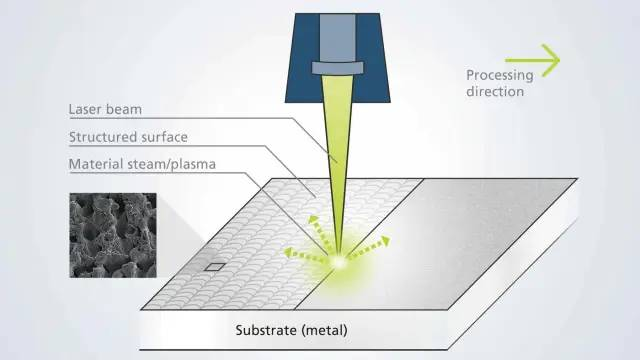

Laser texturingIn this case, the laser creates uniformly distributed geometries within the surface layer or substrate, which can be targeted to change the material's properties and create new functions. For example, the use of lasers forroughening of surfacesProcessing or introductionSmooth textureto achieve the desired sliding properties of the material. The individual elements of such textures are usually only a few micrometers in size.

Short laser pulses generate high energy densities at very high pulse powers, thus vaporizing (sublimating) most materials directly.The laser pulse generates only one fine line per pulse. At the same time, each laser pulse produces only one fine grain, virtually eliminating the metal melt or debris that would be produced by conventional processing.

With laser texturing, uniformly distributed geometric shapes can be reproducibly produced on a surface by the action of laser radiation, primarily pulses. The laser beam will controllably melt the material, which is then cured to a predefined texture by an appropriate process control system.

Laser texturing can produce certain properties in materials that affect, for example, friction properties, electrical conductivity or thermal conductivity, etc. In addition, laser texturing can be used to enhance the adhesion and durability of parts. In addition, laser texturing can be used to enhance the adhesion and durability of parts.

Texturing Applications

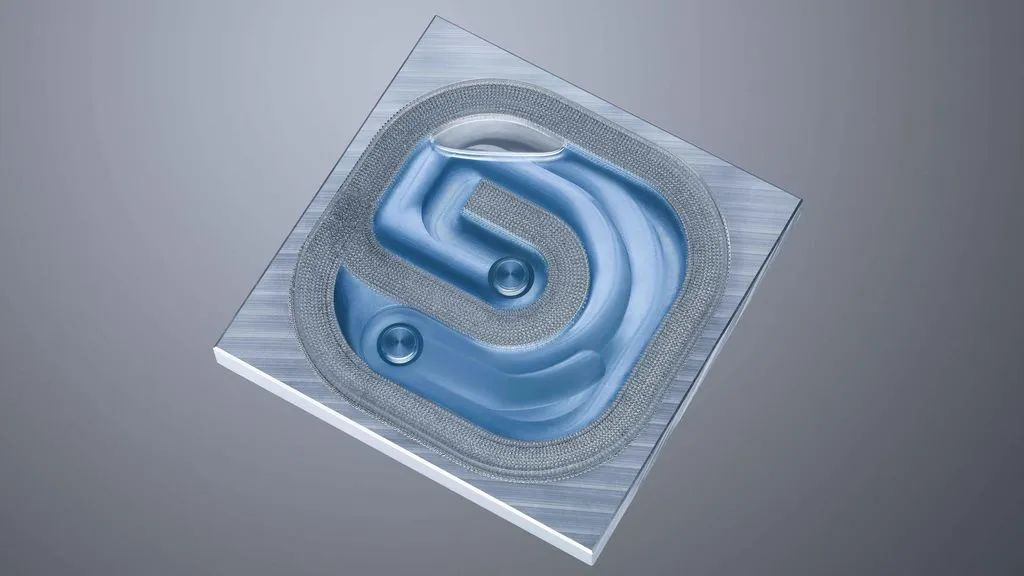

01 Connection of components in heat exchange systems

The laser produces undercut microtextures in the metal bonding material, firmly bonding the composite material to the metal surface. This connection occurs in cooling and heating systems, such as in battery packs.Battery System CoolingIn the center. Ensures good operating conditions for battery system cooling.

02 Preparing for gluing

Laminating TechnologyClean and slightly textured surfaces of the parts are required. In a pre-bonding step, a laser is used to texturize and clean the local joints. Texturizing results in better wetting of the bonding material. This improves the adhesion and long-term stability of the bonded connection. This laser process can be easily integrated into automated production lines.

03 Laser texturing of connecting rods

Friction characteristics of functional surfaces can be precisely modified by laser texturizing. The process can be used forManufacture of automotive components。

04 Connection of metals and synthetic materials

Laser lasers create microtextures with undercuts in metal bonding materials, resulting in a strong bond between the composite material and the metal surface. This process is used, for example, in the manufacture of automobile parts or white goods. Metal-composite composites are playing an increasingly important role in lightweight construction because they combine the high strength and rigidity of metals with the light weight and design freedom of plastics.

How to control the quality of the process immediately?

Honghong's partner New Infrared Technologies (NIT) has developed aHigh-speed non-cooled infrared cameraThe laser process for the LAMPAS project was satisfied.The camera will be able to detect in-line the heat accumulated during the laser surface texturing process.The camera became one of the most important technologies integrated in the LAMpAS online surveillance system. The camera became one of the key technologies integrated in the LAMpAS online surveillance system.

Tachyon 16K at NITAn upgraded version of the camera, this camera utilizes a very unique sensor technology that allows the camera to be used in theNon-cooledFocal plane arrays with excellent sensitivity in the MWIR spectral range (1-5 microns) are processed in this case.

Camera upgrades developed for LAMpAS allow for a snapshot configuration in theCaptures over 4000 full resolution (128×128) images per secondNew features such as flexible RoI (region of interest) selection and new AR coatings for optics and windows as well as integrated NUC (non-uniformity correction) have been realized. New features such as flexible RoI (Region of Interest) selection, new AR coatings for optics and windows, and integrated NUC (Non-Uniformity Correction) have been implemented.

innovativeTexture monitoring technology

LAMpAS Project Monitoring System IntegrationHigh-speed infrared imaging和Instant FFT(Two technologies, Fast Fourier Transform (FFT), are used for online monitoring of laser surface texturing processes. This innovation is aimed at the early detection of instabilities and machining defects in microscopic fine machining processes directly using the laser interferogram method.

However, with LAMpAS' prototype online monitoring system, combined with a high-speed CIR camera, the solution is now available. It'sThe principle of operation is to use the mathematical method of Fourier analysis to detect and process the light reflected from the laser processing area.。

The recorded images are then analyzed by an algorithm that reveals the reflective patterns of theChanges in shape and brightnessIt is therefore easy to detect small deviations in the surface appearance of the processed ground during the manufacturing process. As a result, small deviations in the surface appearance of the processed ground during the manufacturing process can be easily detected, and critical information about the manufacturing process can be provided to the user.

To learn moreProduct InformationWant to get in touch with us? Feel free to contact us!