Water is one of the indispensable necessities in daily life, the good or bad quality of a water plant's water supply is directly related to the health and safety of the general public, and also affects the development of the city and the environment open to the outside world. In order to maximize the improvement of natural water quality and low energy consumption of water plants, the demand for automatic control is greatly enhanced.

Problems encountered with PLCs in water plants

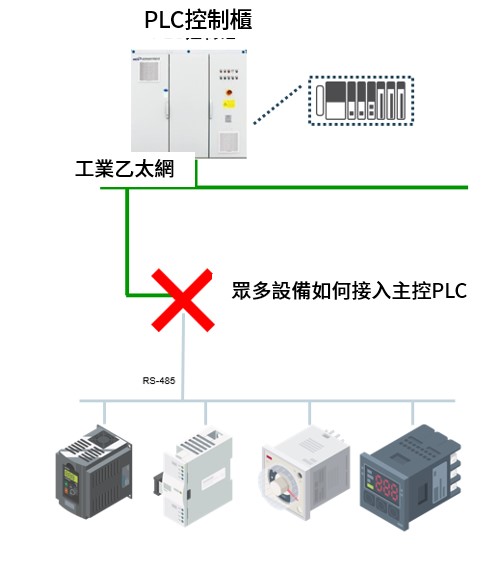

Typical treatment process is water intake → coagulation → sedimentation → filtration → disinfection and water delivery, and PLC has a large number of applications in the automation system, which creates many problems.

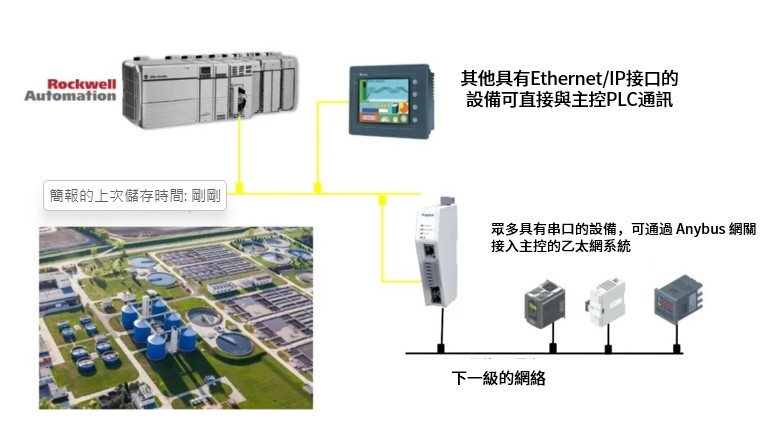

In each PLC sub-system, there are a large number of serial devices need to access the PLC, such as: inverters, relay protectors, flow meters, motor protection and a variety of instruments. In the face of such a large number of devices, the use of traditional PLC expansion communication cards, not only in the number of demand can not be met, the topological structure of the system is not very reasonable, to find a reliable college gateway products, can be effectively integrated into the PLC equipment in the industrial Ethernet system.

The gateway products are simple and easy to use, with powerful debugging functions and expert college services, which can effectively solve the problem of compatibility of different equipment from different manufacturers, which will be encountered after on-site debugging.

Anybus Serial Gateway Solves Communication Problems

Anybus serial gateway can connect any serial RS232/422/485 devices to any mainstream fieldbus or industrial Ethernet network. Many field devices in the water plant can be connected to the main PLC system through the Anybus gateway.

Products

- Web-based drag-and-drop configuration interface

- Bi-directional transfer of up to 1500 bytes of data (requires large forward open)

- -25 to +70 °C Industrial Temperature Range

- Supported by the award-winning NP40 network processor

- Secure Chip, Secure Switch and Secure Activation

Contact Us