Pickering Customized Products Undergo Automated, Highly Accelerated Stress Screening Tests

Client :

TBG solutions is a British company specializing in test measurement and control. TGB works with its customers to understand their needs, identifying problems at their root and then providing effective solutions from its hardware and software engineers. Over the past 15 years, the company has successfully delivered more than 300 projects and maximized the use of advanced technology to meet the changing needs of its customers.

Application Areas .

In the defense industry, such as avionics, manufacturing defects and reliability issues can lead to serious problems, some with disastrous and fatal consequences. To avoid these problems, OEMs need to perform Highly Accelerated Stress Screening (HASS) testing to ensure product quality and reliability by exposing potential defects in product components or assemblies. HASS is a production screening technique that quickly reveals defects in a product's process or manufacturing procedure. The goal is to optimize production screening without compromising product reliability. Unlike HALT, HASS uses non-destructive limiting temperature stresses and rates of temperature change.

TBG Solutions needed to develop a solution that could simultaneously test the inputs and outputs of three avionics PCBs. This required multiple processes to be run in parallel for each test cell during a HASS test, each with 500 test points covering a wide range of signal types. The previous test system was based on BPIB and VXI buses, but due to bus limitations, the results could not be obtained in a timely manner.

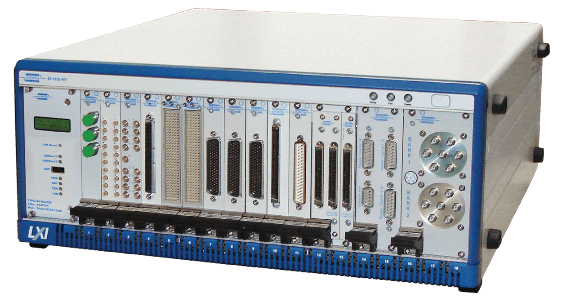

Figure 1 LXI Matrix Module ( *Model: 60 103B 991 )

Solution.

TBG Solutions works closely with Pickering Interfaces, a company that specializes in automated production test and measurement switching solutions, and requires Pickering's PXI and LXI switching products when designing a complete automated test system.

This test system will perform 50,000 electrical tests including voltage, resistance, current, capacitance, frequency, phase and travel on three parallel units in a HASS test procedure. The test system generates and executes HASS profiles that allow operators to add or remove specific tests, adjust temperature, vibration level and slope. The fully automated parallel test design includes on-board simulation, two-part firmware download, highly accurate capacitance measurements, and load trip testing.

TBG Solutions built the system using CAD and computer aids, and controlled it with NI's Labview and TestStand. They decided to use a Pickering 18-slot LXI chassis (Model 60-103B-001) with a full set of Pickering's PXI switch cards, including high power switches, matrix, RF switches, etc., and three Pickering LXI matrix modules (60-551-024 256 X4) with internal relay self-test to facilitate accurate and flexible operation. 551-024 256 X4) from Pickering with internal relay self-test (BIRST) for accurate and flexible testing. TBG created interface drivers for each part of the system, which are very compatible with the API provided by Pickering, allowing them the flexibility to seamlessly connect these drivers to the rest of the test system for on-aircraft sequencing. The TBG takes full advantage of the switching system to test three units in a parallel batch, starting and ending the test at the same time.

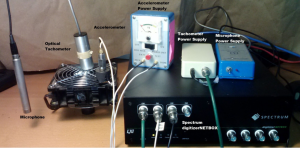

Fig. 2 Test system designed for Pickering's switching products.

“Our team decided to use Pickering's PXI and LXI switching products for this project because they are very flexible and easy to maintain, and both of these advantages will make development and maintenance very easy for us now and in the future” - Steve Bale , Director, TBG Solutions TBG Solutions

System Advantages.

The test system not only solved the problem of testing three units in parallel, but also reduced the test time per unit from 3 hours to 45 minutes. This means that we have increased test speeds by a factor of 12, significantly reducing costs for manufacturers and end customers.

Using the system tools, the operator can change the test sequence, cycles, and HASS parameters such as vibration intensity, temperature, and the respective heating rate. The operator can create a specific profile to simulate specific component failures in a real environment. Due to the great flexibility of the system, the operator can carry out diagnostics, debugging, testing as well as research and development.

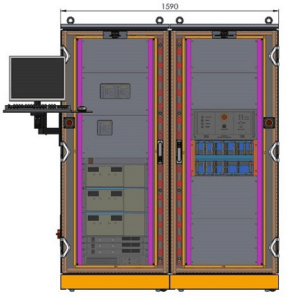

Figure 3 shows a CAD drawing of the front panel of a 19-inch rack that houses a PXI chassis and an LXI matrix.

Conclusion.

Pickering Interface offers a range of flexible, easy-to-use modular switching systems like this one, so that our test system developers and designers can better focus on how to best perform the inspection of the unit under test, rather than designing complex interconnections and circuits. The TBG team used Pickering's LXI and PXI switching products to build a flexible, reliable, and low-maintenance test system that provides a better experience for the end customer. Pickering's BIRST self-diagnostic system ensures that the signaling switches are in good working condition, making it easy to detect system problems and ensure the accuracy of measurements.

Guangzhou Hongke Electronics, as Pickering's agent in China, provides you with the best products and perfect solutions.