Honghong will provide you with any support you need!

Our professional Honghong team will be the first to respond and provide you with the best service to solve all your problems.

Honghong NIT Infrared Camera Series

Covering short-wave (SWIR), medium-wave (MWIR) and long-wave (LWIR) infrared bands, it meets the high-precision requirements of different application fields.

Short-wave infrared cameras based on different sensor materials: BeyonSense 1 based on germanium, which is 5 times lighter and 10 times cheaper than a typical SWIR camera, and GaAs-based high-performance short-wave infrared cameras, which combine high sensitivity with stable image quality.

High-speed MIR industrial camera: A cost-effective choice for machine vision with frame rates up to 1000 Hz. Miniature MIR camera for industrial production lines with a peak wavelength of 3.7 μm and a maintenance-free design to effectively reduce costs.

Long-wavelength infrared camera: Compact size, industrial connectivity and Industry 4.0-oriented features make it the ideal system for industrial IoT and machine vision applications.

The world's first smartphone-compatible shortwave infrared camera that supports Android, Windows, and iOS systems. It can be operated via wireless connection to BeyonSense's proprietary application.

Adopting Ge-based shortwave infrared technology, it is 5 times lighter, 10 times more energy-efficient and 10 times cheaper than a typical SWIR camera.

Support 5V/1A USB power supply, standard version with C lens and built-in 800-1700nm pass filter (visible light cutoff). It is suitable for various short-wave infrared imaging tests, laboratory scenes, and in-line inspection for industrial research.

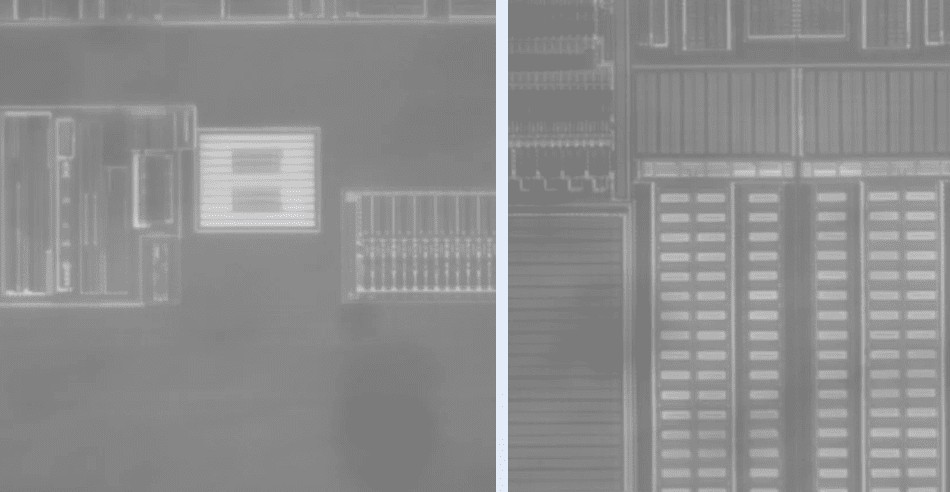

USB3.0 interface short-wave infrared camera utilizing SONY IMX991 SENSWIR InGaAs sensor.

With 400nm-1700nm wideband response, 330,000 pixels high resolution, high quantum efficiency and high sensitivity, it provides stable and accurate image performance in various applications.

It is suitable for semiconductor inspection, near-infrared two-region in vivo microscopic imaging, high spectral imaging, laser spot observation, machine vision, infrared detection, spot photography and analysis, and many other application scenarios.

Uncooled high-speed mid-infrared industrial camera with built-in self-developed VPD PbSe infrared sensor, frame rate up to 4000fps, and IP67-grade protective metal casing for durability.

Wide range of applications in additive manufacturing, industrial process monitoring, machine vision, gas and flame detection, spectroscopy, and glass manufacturing quality control.

Compact size (66 × 62 × 62 mm) with a minimum detectable temperature of 100°C, allowing accurate imaging and monitoring in high-temperature environments. It enables precise imaging and monitoring in high-temperature environments.

Cost-effective choice for machine vision: Frame rate up to 1000Hz, miniature MIR camera for industrial production lines, peak wavelength 3.7μm.

Convenient connection, plug and play: USB2.0 high-speed communication interface (480Mbps), the back of the industrial-grade M12 micro USB connector, stable and durable.

Wide range of industrial and system integration applications: including industrial process control (welding, cutting, etc.), laser process monitoring, gas and flame detection, machine vision and OEM integration applications.

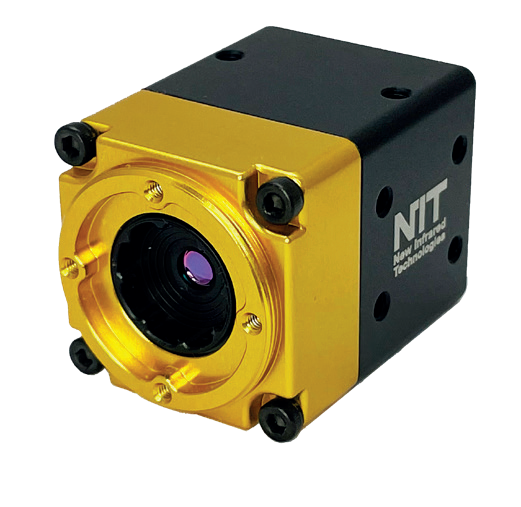

Compact design with industrial-grade connectivity and Industry 4.0-oriented features. Ideal for industrial IoT and machine vision applications.

With 320×240 pixel resolution and 12μm pixel pitch. Provides 4mm and 9.1mm optical options, and outputs calibrated, high-quality thermal images at a 27fps frame rate.

With professional visualization software, it can be flexibly applied to a variety of industrial scenarios to achieve the best balance between cost-effectiveness and performance.

Focusing on the photovoltaic industry, combining application scenarios and technical advantages, Honghong provides you with customized integrated solutions.

Outstanding, fearless comparison! With six core advantages, it leads the new standard of infrared imaging technology.

We offer a wide range of shortwave, mediumwave and longwave infrared cameras covering a wide range of wavelengths to meet the needs of various project applications.

Provides miniature short-wave infrared cameras made of platinum-based materials, realizing high performance and efficiency at low cost.

The Gallium-Arsenic (GaAs) sensor chip has a wide wavelength range of 400nm-1700nm.

The high-speed MIR camera has a frame rate of up to 4000 fps to support a wide range of industrial manufacturing and scientific research applications.

Provides miniature MIR cameras with frame rates up to 1000Hz and peak wavelengths of 3.7μm, suitable for various industrial line applications.

Compact dimensions, industrial-grade connectivity pages and functional design for Industry 4.0

BeyonSense Mini Shortwave Infrared Camera:

SWIR 330KMA / 1300KMA:

High-speed mid-infrared industrial camera: Uncooled high-speed mid-infrared industrial camera with integrated self-developed VPD PbSe infrared sensor, frame rate up to 4000fps.

Compact size, high temperature probing: The metal housing is IP67 rated and measures 66 (L) × 62 (W) × 62 (H), and can detect temperatures down to 100°C. The temperature range is from 0.5°C to 0.5°C.

Rich industrial and research applications: Suitable for additive manufacturing, industrial process monitoring, machine vision, gas and flame detection, spectroscopy, glass process quality control and R&D.

Machine Vision is a cost-effective choice: Frame rates up to 1000 Hz for industrial production line miniature MIR cameras with a peak wavelength of 3.7 μm.

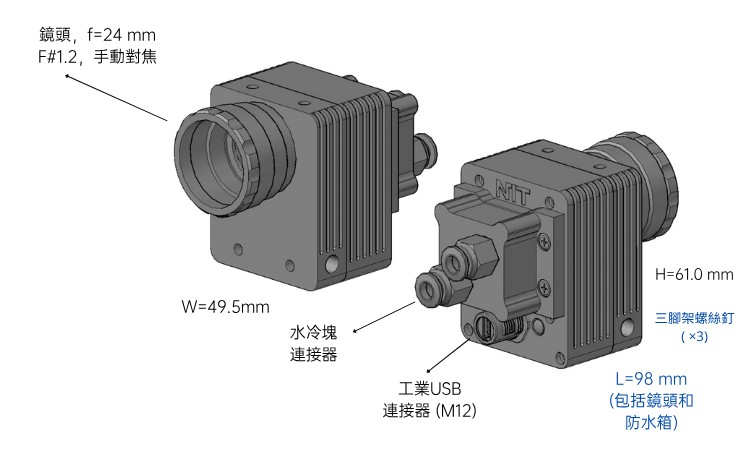

Conveniently connected, plug and play: Utilizes USB2.0 interface to support high-speed communication (480Mbps) and features an industrial-grade M12 micro USB connector.

Multiple application scenarios: It can be applied to industrial process control (welding, cutting, etc.), laser process monitoring, gas and flame detection, machine vision and OEM system integration.

High performance thermal imaging camera: The VST LIR320 features a compact form factor, industrial-grade connectivity and functional design for Industry 4.0.

It is an ideal system for industrial IoT and machine vision applications.

The thermal image quality has been corrected: With 320×240 resolution and 12μm pixel pitch, it offers 4mm and 9.1mm optical options.

Outputs high-quality, calibrated thermal images at a frame rate of 27fps.

Wide range of applications with visualization software: The LIR320 is a cost-effective imaging solution.

It meets the needs of various industrial applications and provides stable and excellent image performance.

BeyonSense shortwave infrared cameras have already been introduced in a number of fields, and the main applications include:

Infrared light source and lamp bead inspection: Lighting quality and wavelength consistency testing by infrared light source and LED lamp bead manufacturers.

Infrared laser laboratory testing: It is used in scientific research units to analyze the output and spot characteristics of infrared lasers.

Used by measurement and testing organizations: For example, metrology and optical inspection related organizations for equipment calibration and performance testing.

Universities and research institutes apply: It is involved in the fields of agricultural product quality analysis, spectroscopic detection and primary infrared research.

With the advantages of light weight, high sensitivity and cost-effectiveness, BeyonSense has become the ideal choice for short-wave infrared detection in research and industrial applications.

Welcome to contact Honghong team, our professional technical engineers will assist you in camera selection and provide complete customized solutions according to project requirements.

Data Interface: Wireless transmission design. The camera can set up its own Wi-Fi hotspot for wireless control and image transfer from a cell phone or computer.

Power Supply Interface: Use USB-A to USB-microB cable for power supply only (5V/1A), data transfer function is not supported.

As the camera utilizes the latestGe Sensor and Process TechnologyThe structure is different from that of a conventional photodiode, and therefore the QE (quantum efficiency) The test is also different.

The current spectral response range is 400-1700nmThe QE data is available in a variety of formats, and several imaging examples are available. Specific QE data is subject to validation and testing of various methods before more detailed test results can be provided.

Honghong's professional technical team is at your service. With many years of experience in machine vision and optoelectronic inspection, we have successfully built a number of mature customized projects.

Our professional Honghong team will be the first to respond and provide you with the best service to solve all your problems.

Address: 3F, No. 99, Jingye 1st Road, Zhongshan District, Taipei City, Taiwan (Da Wan Technology Center Building)

3rd Floor., Dawan Technology Center Building, No. 99 Jingye 1st Road, Zhongshan District, Taipei City, Taiwan

©2025.hongtronics. All Rights Reserved.