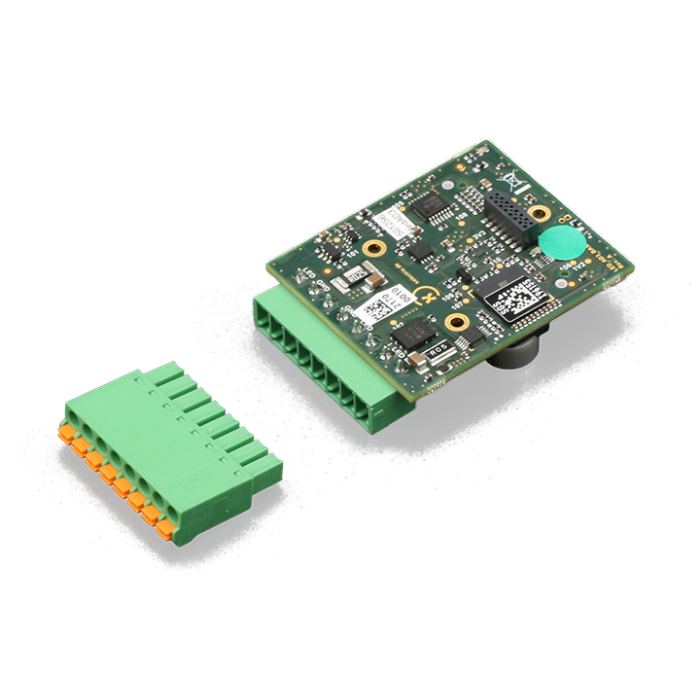

ledAD3 Basic LED Adapter Plug-in Module

Functional overview:

- Suitable platforms: proFRAME 3.0 baseboard PCIe, supports synchronization with camera modules.

- Core functionsLEDs: Up to 60 Hz / 6 ms operating frequency, supports 2.5 A pulse length, LED current adjustable.

- Advanced AdjustmentPulse rate and duty cycle are adjustable, and a built-in 12-bit ADC provides accurate current measurement.

- Durable EnvironmentThe operating temperature range is -20°C to +60°C, making it stable for use in a wide variety of scenarios.

Description

Product Parameters

| descriptive | Basic LED adapter plug-in module for installation on proFRAME 3.0 baseboards, designed to power illumination LEDs and synchronize with the camera adapter (camAD3). |

|---|---|

| Standalone Driver Interface | One of 2 independent LED driver interfaces (ledAD3 Base + ledAD3 Expansion) |

| Operating Frequency | Up to 60 Hz / 6 ms pulse length |

| Pulse Current | Supports 2.5 A pulse lengths |

| Adjustable parameters |

|

| Current Measurement | 12-bit ADC for accurate current measurement |

| Operating Temperature Range | -20 °C to +60 °C |

Applications

Hardware-in-the-Loop (HiL) Systems

Realize analogies and simulations of the system.

It can capture HD video data in real time and synchronize it with other systems.

Provides more comprehensive data support for HiL testing.

ADAS development, diagnosis and validation

real-time analysis of road conditions, vehicle and pedestrian information.

and diagnose and verify the functionality and performance of the ADAS system.

Ensure system stability and accuracy.

Digital Microscope Technology

Researchers in the fields of biology, medicine, materials science, etc. can use proFRAME

Observe microstructures, perform image analysis and measurements, and promote the progress of scientific research.

EOL Testing

Testing and evaluating to ensure product compliance.

At the same time, it can help optimize production line efficiency and quality management.

- Supplement I

- Supplement II

- Supplement III

- Supplement IV

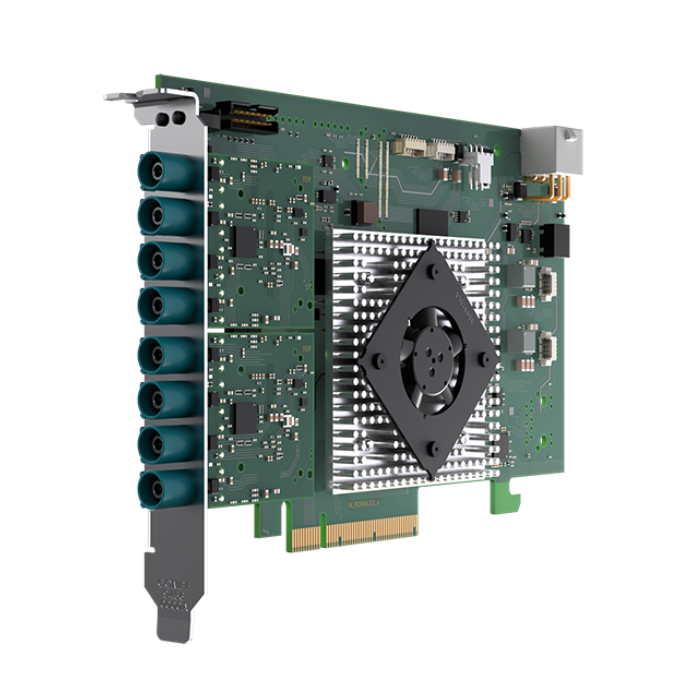

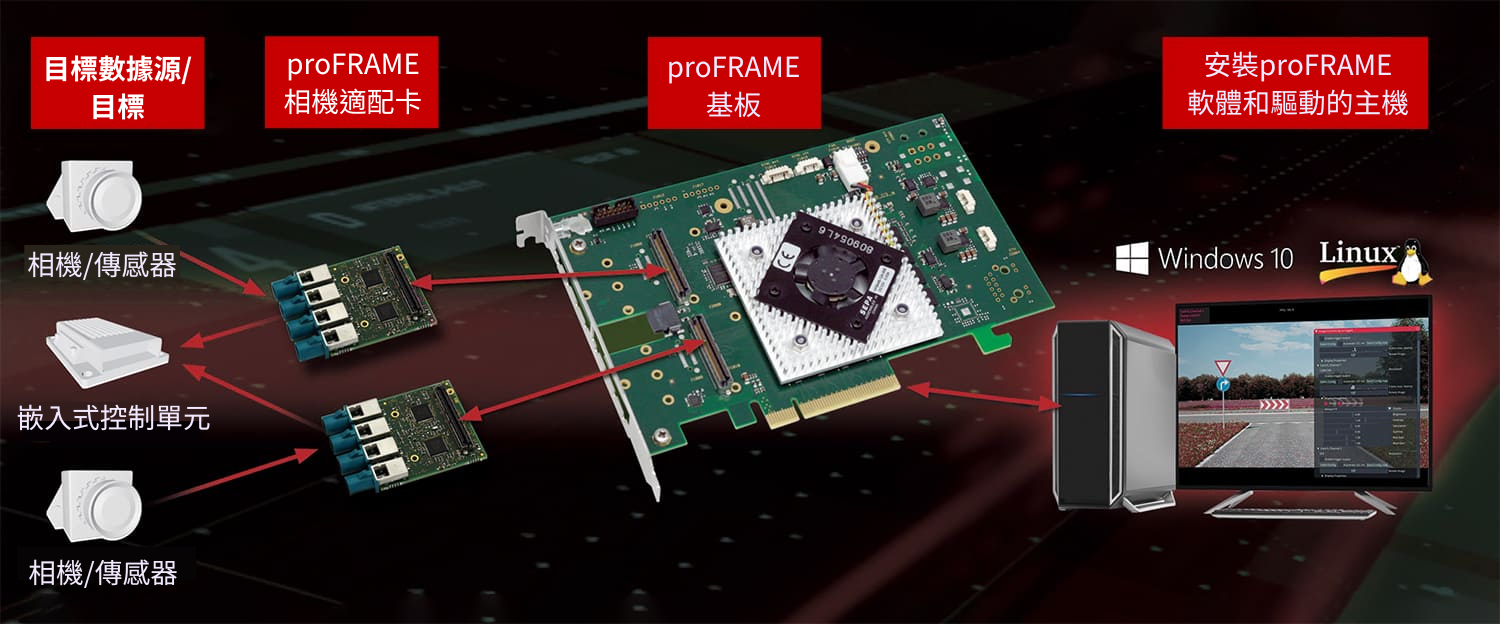

Modular system consisting of three parts with system accessories

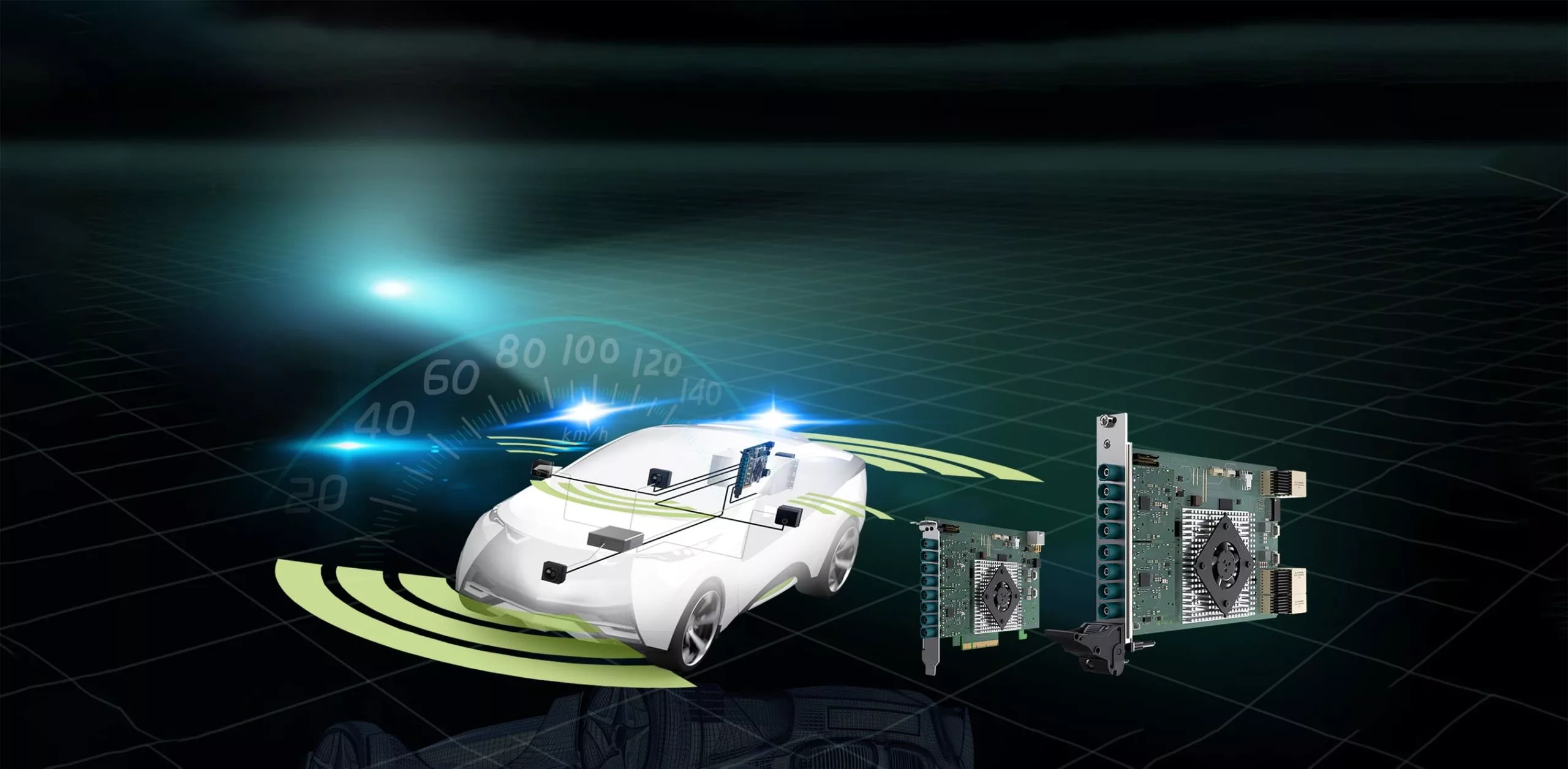

Comprised of a proFRAME baseboard, camera adapter and supporting software, the system is flexible enough to be used with a wide range of system accessories, and supports major transmission technologies such as GMSL2™, GMSL3™, FPD-Link™ III and IV (other technologies are available upon request). The system is capable of efficiently processing raw video data streams for a variety of applications, ranging from ADAS system validation and self-driving function testing in the automotive field to industrialized applications such as medical technology, digital microscopy, and EOL testing.

Validate ADAS/AD embedded control units as intermediate media

In Hardware-in-the-Loop (HiL) testing of ADAS or Autonomous Driving (AD) functionality, the ADAS/AD Embedded Control Unit (ECU) provides driving scenes via video streams recorded during the test drive and relies on precise time stamping for synchronized replay of the video frames. proFRAME systems can efficiently and accurately replay driving scenes in HiL testing, thus enhancing the efficiency of ADAS/AD functionality validation. AD function verification efficiency. Equipped with various camera adapters, the system is compatible with the leading serializers in the market (e.g. GMSL and FPD-Link) and can replay video streams based on single-frame timestamps or external triggers. proFRAME supports the replay of video streams based on single-frame timestamps or external triggers. In addition, proFRAME supports HiL system integration based on ROS or ADTF platforms, providing fast connection between SW APIs and software platforms through proprietary ROS™ packages (ROS 2) and ADTF plug-ins, enabling seamless integration with HiL systems.

High-performance system captures multiple camera data streams

ADAS system functions such as traffic sign recognition, lane assistance, parking assistance, and autonomous driving require efficient and accurate collection of real-time data from vehicle sensors, especially the video streams generated by embedded cameras. To validate these capabilities, the video streams from each camera need to be captured synchronously, accurately time-stamped and stored, and then replayed in a hardware-in-the-loop (HiL) test of the driving scene to validate the performance of the ADAS/AD ECU. proFRAME system is the ideal solution for this, supporting most common automotive cameras and recording up to eight 4K video streams synchronously (including I2C sideband communication). The time stamping of the input data is precisely processed by the hardware and can be synchronized with other devices via an external trigger cable. The camera also provides configurable voltage via a coaxial cable (supporting PoC power) for further application flexibility.

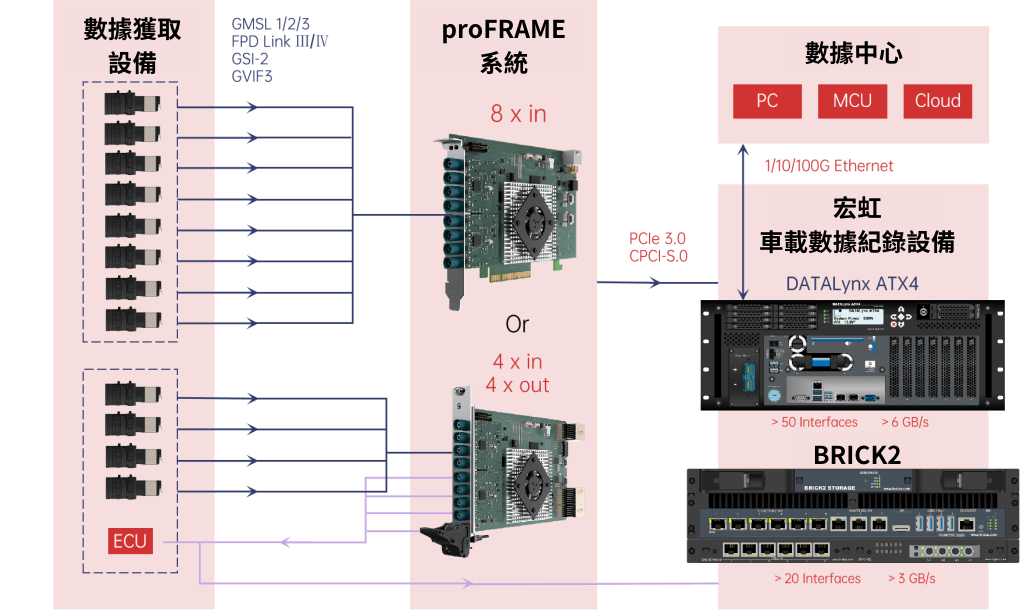

Integration of data acquisition equipment for data recording and analysis

The multiphase data flow includes precise, high-precision time stamping, and the proFRAME system supports bypass functionality for simultaneous data input acquisition and output processing. Through the ATX4 high-performance on-board server or BRICK2 data acquisition platform, the system is able to store, process and analyze the data in-depth, thus creating a complete closed-loop process from on-board multiphase image acquisition to analysis result output and storage, meeting the demand for efficient data processing.

Frequently Asked Questions

- MaxicoM: GMSL2™ and GMSL3™

- TI: FPD-Link™ III and IV

- Sony Semiconductor: GVIF (other technologies available upon request)

proFRAME supports synchronization of multiple cameras per substrate as well as synchronization of multiple substrates. With the proFRAME SYNC adapter, synchronization signals for camera triggering can be taken from an external trigger source and generated on our proFRAME boards. These signals can be sent to the camera or to an external trigger receiver. The adapter is available as input/output and dual input.

As proFRAME has the ability to capture, replay and process raw video data streams in a variety of applications. The system is used in the automotive field to validate ADAS systems, hardware in-situ testing or autonomous driving functions. proFRAME is also used in industrialized applications in medical technology, digital microscopy (e.g. sinaSCOPE, a 3D digital microscopy platform) and end-of-line testing.

You can contact our staff with project information and our machine vision team will provide you with professional selection services.

Honghong will provide you with any support you need!

Our professional Honghong team will be the first to respond and provide you with the best service to solve all your problems.