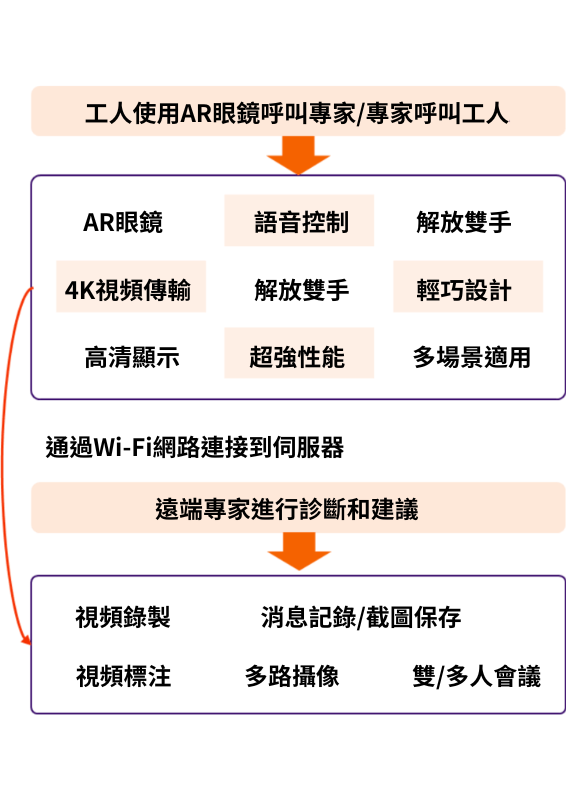

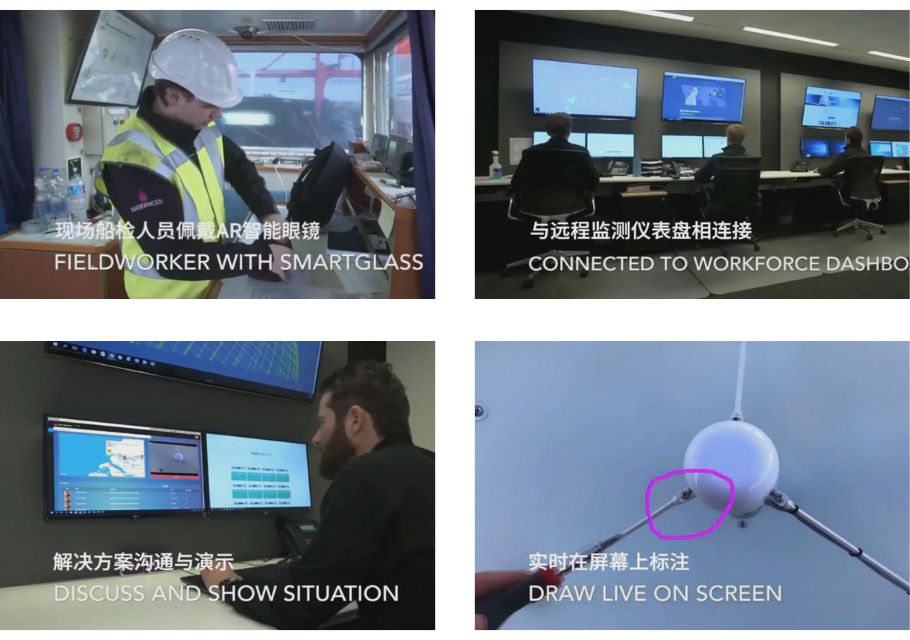

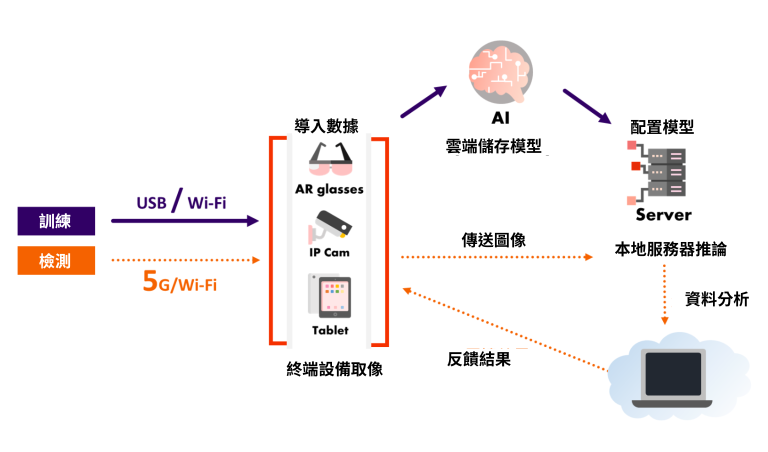

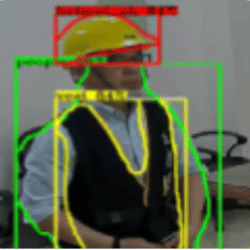

AR Ship Industry Solutions

Utilizing AR glasses and AI function, it solves the problems of ship maintenance, such as hands being occupied, data being difficult to obtain instantly, insufficient first view angle, and difficulties in the recording process, etc. It effectively improves the operation efficiency and supports the whole process of traceability, which is suitable for various scenarios such as classification societies, shipyards, and so on.