01 Case background

The benefits of using pressure sensors are no secret. The ability to convert pressure in the physical world into a voltage signal that we can analyze with an oscilloscope allows us to quantify things that we would otherwise be unable to do.

If you are not familiar with the use of pressure sensors, variables such as crankshaft speed and throttle position can radically affect the measurements provided by the pressure sensor.

One technique that helps eliminate many variables is to use 2 sensors at the same time. By installing one sensor into a suspect cylinder and the other sensor into the matching cylinder for that cylinder, we now have two traces. We think one of the cylinders may be defective, while the other is hopefully known to be good. Since the measurements were taken at the same time, engine speed, throttle opening, temperature and most other variables have been taken into account and mitigated.

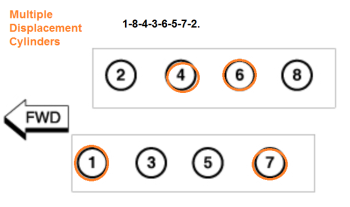

In the following example, we will introduce the 2011 Jeep Grand Cherokee with a 5.7L V8 engine. The driver's complaint is that the engine is running erratically. The check engine light comes on and flashes. The ECM retrieved a P0302 Cylinder 2 misfire diagnostic trouble code. The customer replaced the ignition coil and two spark plugs for cylinder 2. For reference, this engine has a multi-displacement system that disables cylinders 1, 4, 6, and 7.

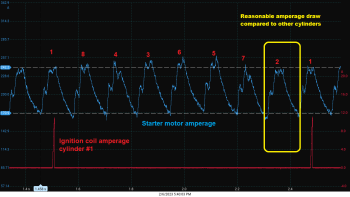

After personally verifying rough running and DTC, a clicking sound was also noted. A relative compression test was performed at this time. While the capture was not the ideal smoothing pattern, it was stable enough to conclude that we were not looking at a massive compression leak.

Ignition coils and injector drivers were also checked and found to be valid.

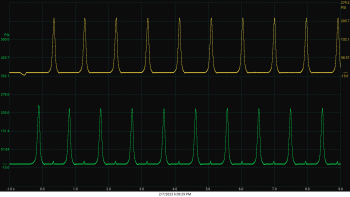

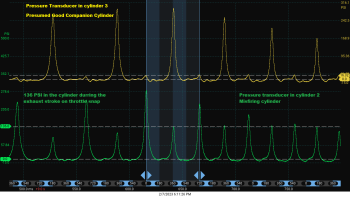

It is time to go to the cylinders. the ignition coils and injectors for cylinders 2 and 3 have been disconnected. The engine's ignition sequence is 1-8-4-3-6-5-7-2, which makes cylinders 2 and 3 companion cylinders. After removing the coils and removing one of the two spark plugs from each cylinder, a pair of WPS 500X pressure sensors were installed. Comparing the start-up compression test of the 2 cylinders began to show the cause of the customer's complaint. The pressure rise at the end of the exhaust stroke in the green track tells us that the pressure in the cylinder rises when one or both valves should open. Keep in mind that this is capturing at start-up speeds, so we usually don't see much activity between the compressor towers.

Next, start the engine and open the throttle a couple of times while running to get the engine revving. Prior to starting the engine, compression peaks at 95 PSI on the suspect cylinder and 102 PSI on the companion cylinder.The real difference can be seen in the pressure rise at the end of the exhaust platform. The pressure rise peaks at idle at close to 50 PSI, and as the engine accelerates, the pressure on cylinder #2 of the exhaust stroke exceeds 130 PSI!

To confirm the diagnosis of a worn camshaft exhaust cam on cylinder #2, the valve cover was removed and the engine was turned by hand. It was observed that the intake valve was lifted open about 1/2” and the exhaust valve was lifted less than 1/8”.

Although this diagnostic does not require the use of 2 sensors, it does make it easier to explain the problem to the customer.

This article is reprinted from the official website of Pico Technology (UK).